Quasi-plastic cuttlefish-imitating pulse jet propeller

A pulse jet, squid-like technology, applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of poor bionic effect, low propulsion speed, low thrust, etc., achieve fast propulsion speed, delay turbulence, and reduce resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

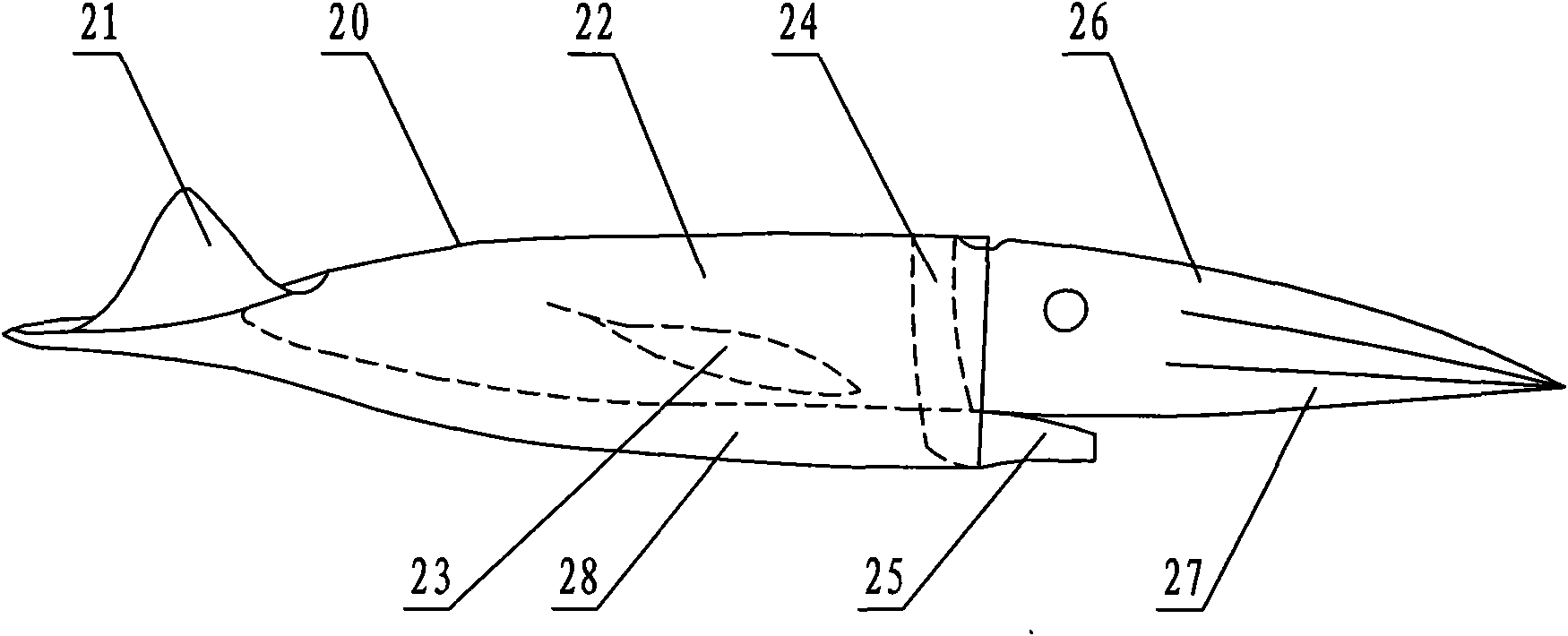

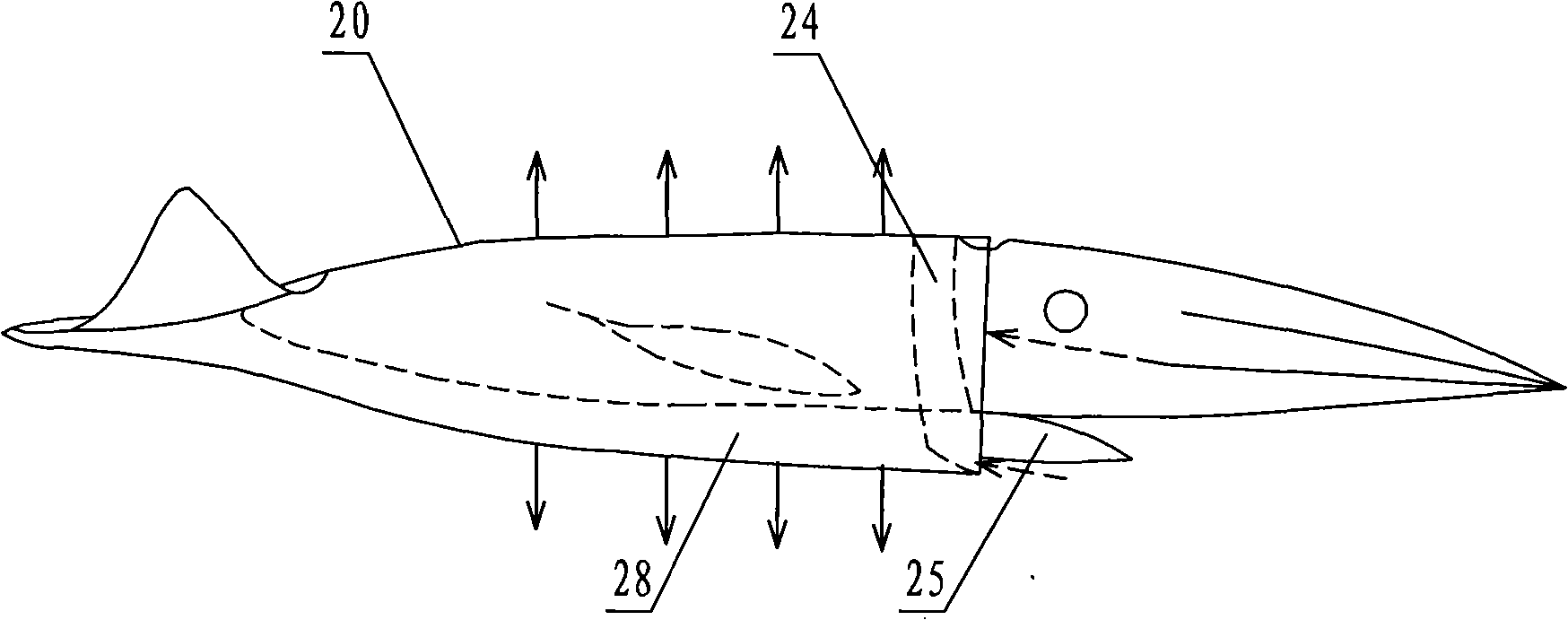

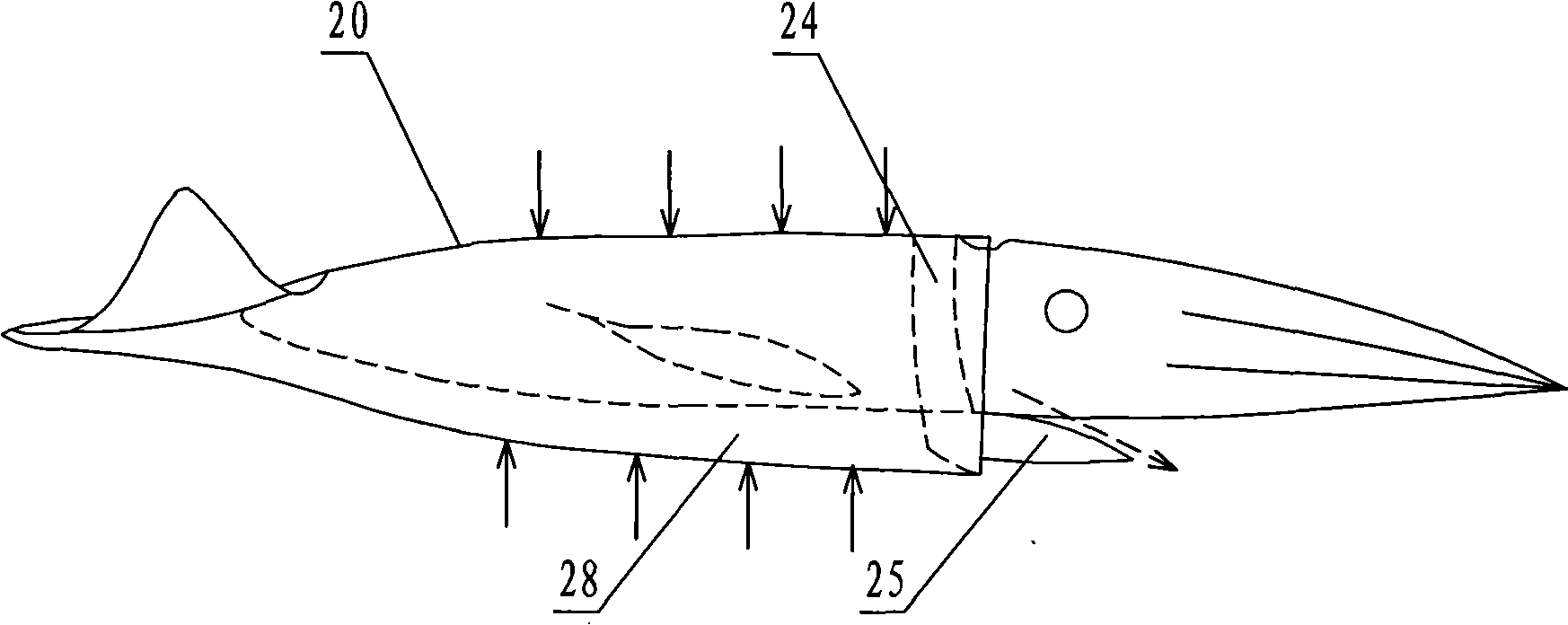

[0020] Specific implementation mode one: combine Figure 7 ~ Figure 10 Describe this embodiment, a kind of quasi-flexible imitation squid pulse jet thruster of this embodiment comprises silica gel funnel 2, imitation squid mantle 3 and cabin body 4, and described imitation squid mantle 3 is made of many shape memory alloy wires 5, The silicone flexible body 6 and a plurality of ribs 7 are composed, the large-diameter end of the silicone funnel 2 is connected to the inner wall of the open end of the imitation squid mantle 3, and the cabin body 4 is arranged in the imitation squid mantle 3, so that A plurality of ribs 7 are evenly embedded in the imitation squid mantle 3 along the circumferential direction of the imitation squid mantle 3, and each rib 7 is arranged along the generatrix direction of the imitation squid mantle 3, and the adjacent two ribs 7 They are connected by a shape memory alloy wire 5, and the shape memory alloy wire 5 is embedded in the imitation squid mantl...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 9 To describe this embodiment, the shape memory alloy wires 5 between two adjacent ribs 7 of this embodiment are arranged in a V shape. In this way, the oblique wiring method with a certain angle to the ribs 7 increases the length of the SMA wires, thereby increasing the relative moving distance between the two ribs 7 . Both ends of the shape memory alloy wires 5 arranged in a V shape are fixed on a rib 7 , and the midpoint of the shape memory alloy wires 5 arranged in a V shape is fixed on another rib 7 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 7 and Figure 8 To illustrate this embodiment, the pulse thruster of this embodiment also has an underwater vector thrust nozzle 1 driven by a shape memory alloy, and the underwater vector thrust nozzle 1 driven by a shape memory alloy is fixed on the small diameter end of the silicone funnel 2 superior. With such arrangement, vector propulsion is realized. The underwater vector thrust nozzle 1 driven by shape memory alloy adopts the vector thrust nozzle disclosed in the patent No. ZL200610010360.5. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertex angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com