Bituminous pavement structure based on traffic condition of soft foundation and heavy load and subgrade processing method

A technology for asphalt pavement and transportation, which is applied to the coagulation pavement, roads, roads and other directions paved on site to achieve the effect of comprehensive cost saving, promotion of progress, and improvement of rebound and deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

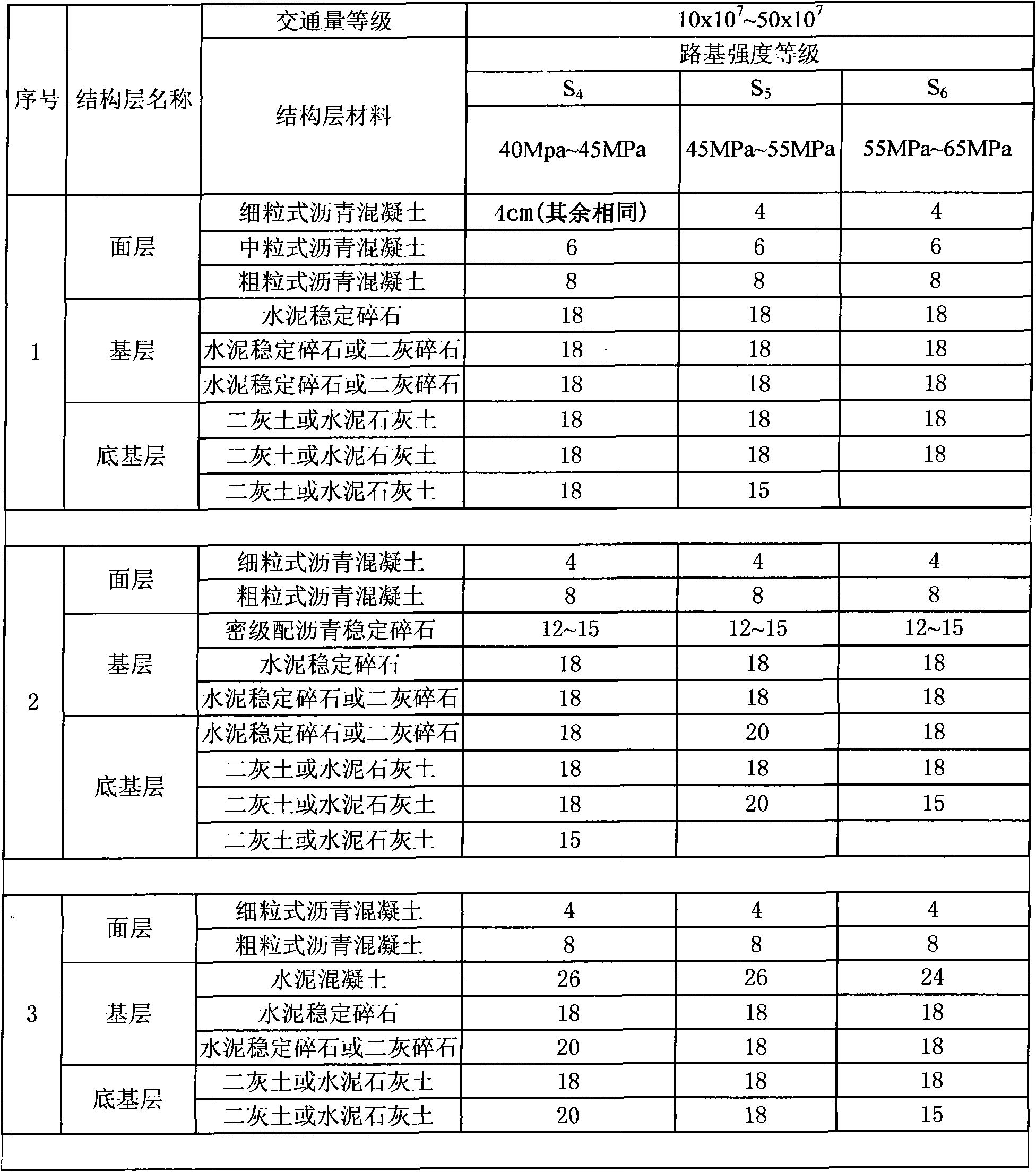

[0044] For a heavy-duty urban expressway on a soft soil foundation, trucks with more than four axles account for 44%, and the cumulative equivalent axle times Ne on a lane within the design period is 67×107 , the road surface elevation is limited by the surrounding elevation and needs to be excavated.

[0045] According to the cumulative number of equivalent axles and the proportion of trucks with more than four axles, the traffic level of the road is determined as special T 2 According to the surrounding elevation, the foundation needs to be excavated. The depth of the subgrade work area is 2.0 meters, and the treatment thickness is also 2.0 meters. The treatment measures are: after dredging and drying, the bottom layer is treated with mixed slag + geogrid + gravel, The thickness of the mixed slag is 70cm, and the thickness of the crushed stone is 50cm. A four-step treatment layer is applied on it. From bottom to top, it is 20cm lime soil (lime 10%)+20cm lime soil (lime 10%)+2...

Embodiment 2

[0051] In a heavy-duty expressway with soft soil foundation, trucks with more than four axles account for 38%, and the cumulative equivalent axle times Ne on a lane within the design period is 35×10 7 , the elevation of the road surface is limited by the crossing passage and bridge structures, and the filling height is between 3.2 and 3.6 meters.

[0052] According to the cumulative number of equivalent axles and the proportion of trucks with more than four axles, the traffic level of the road is determined as special T 1 According to the filling height of the subgrade, it is determined that the subgrade does not need to be excavated. The depth of the subgrade work area is 1.8 meters. The treatment measures are: after the subgrade surface is cleared, fill with 6% lime soil to 80cm below the top of the roadbed, and then fill from bottom to top 40cm lime soil (lime 8%) + 20cm cement lime soil (2% cement + 5% lime) + 20cm cement lime soil (3% cement + 6% lime) for treatment, 20cm...

Embodiment 3

[0059] In a heavy-duty expressway with soft soil foundation, trucks with more than four axles account for 58%, and the cumulative equivalent axle times Ne on a lane within the design period is 3.4×10 9 , the elevation of the road surface is limited by the crossing passage and bridge structures, and the filling height is between 2.5 and 2.8 meters.

[0060] According to the cumulative number of equivalent axles and the proportion of trucks with more than four axles, the traffic level of the road is determined as special T 3 According to the filling height of the subgrade, it is determined that the subgrade does not need to be excavated. The depth of the subgrade work area is 2.3 meters. The treatment measures are: after the subgrade surface is cleared, fill with 6% lime soil to 100cm below the top of the roadbed, and then fill from bottom to top 60cm lime soil (lime 8%) + 20cm cement lime soil (2% cement + 6% lime) + 20cm cement lime soil (4% cement + 6% lime) for treatment, 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com