Mechanical seal test system for nuclear main pump

A mechanical seal and experimental testing technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, to achieve the effect of stabilizing pressure and reducing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

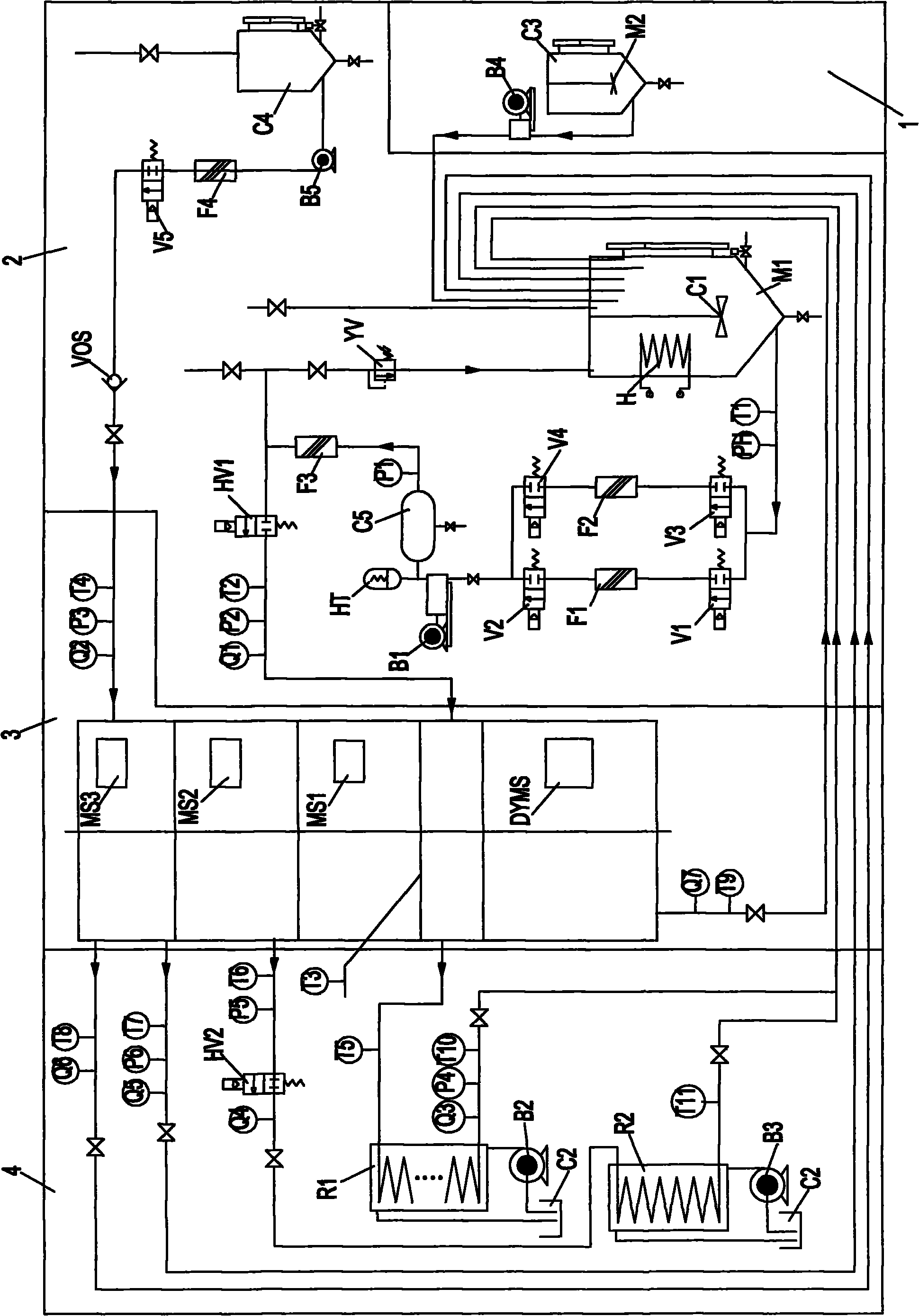

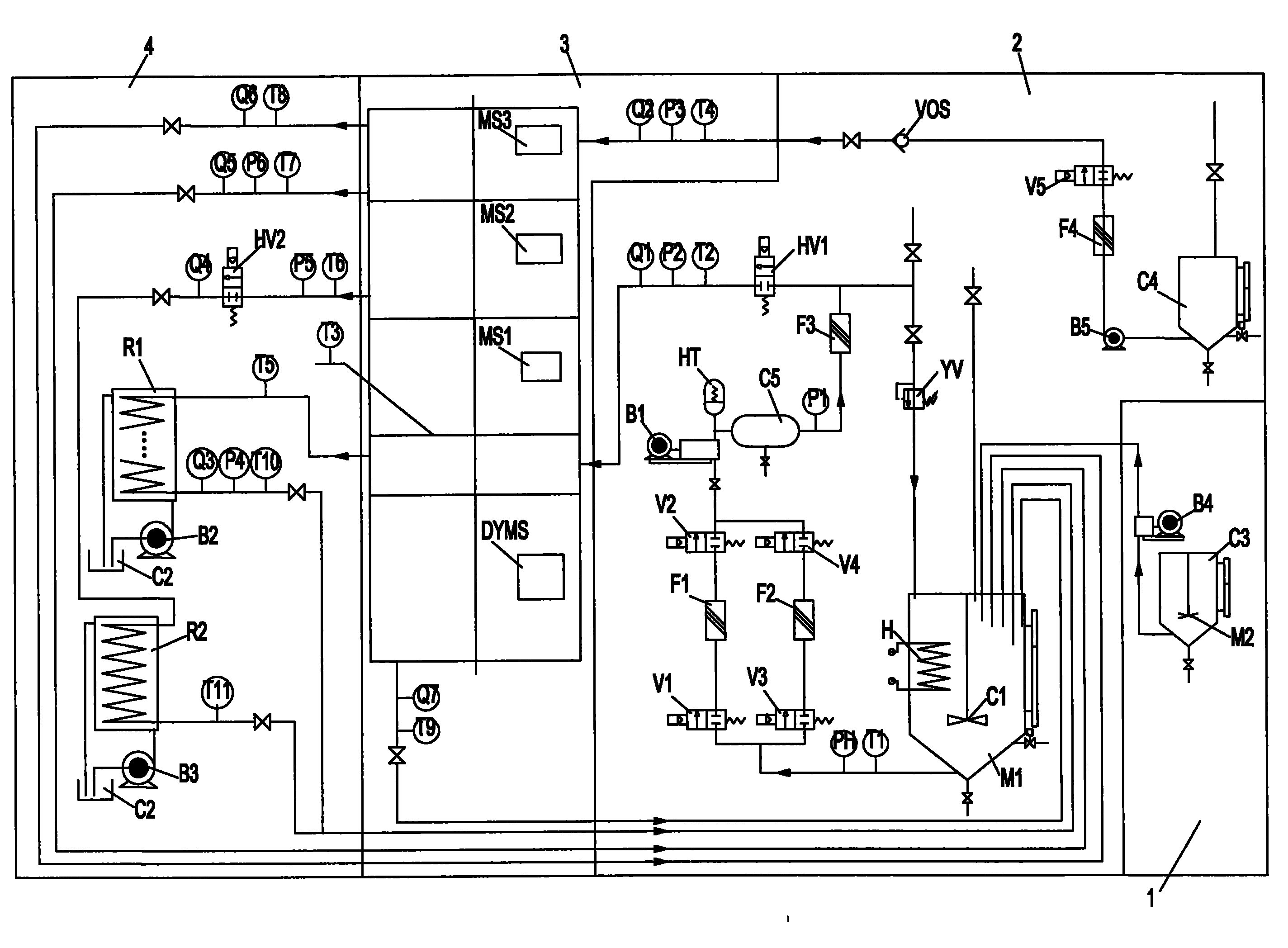

[0023] see figure 1 , the test system of this embodiment consists of a medium concentration control zone (1), an injection medium treatment zone (2), a bench zone (3) and a backflow medium post-treatment zone (4) including leakage, backflow, back pressure and cooling. );in:

[0024] In the bench area (3), the driving force is provided by the frequency conversion motor, and the test spindle is the driven part; a hydrostatic seal or a hydrodynamic seal or a hydrodynamic seal and a static seal are arranged in series on the test shaft. Combined seal with high pressure; the frequency conversion motor can be directly connected to the output, or the output can be output by belt transmission, and the stepless speed regulation can be realized through the frequency converter.

[0025] In the injection medium treatment area (2), a stirrer M1 for stirring the medium is set in the low-pressure container C1 to prevent the crystallization of the medium, keep the concentration of the medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com