Full-automatic lensmeter

A focal meter, fully automatic technology, applied in the field of focal meter, can solve problems such as troublesome operation, offset of reticle center, displacement of cylinder lens axis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

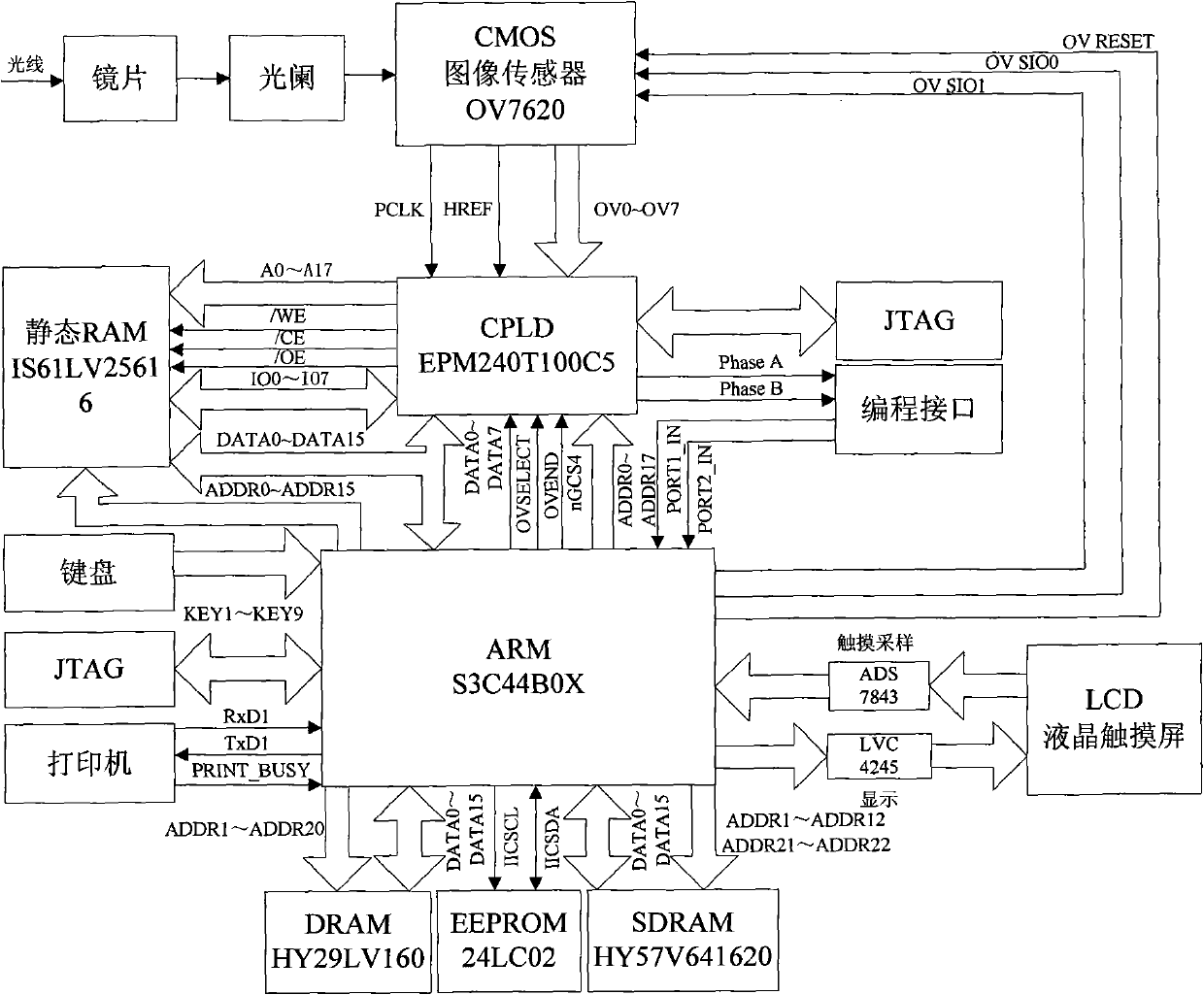

[0062] refer to Figure 1 to Figure 9 , a fully automatic lens meter, comprising: an image sensor, used to collect light signals passing through the lens to be detected;

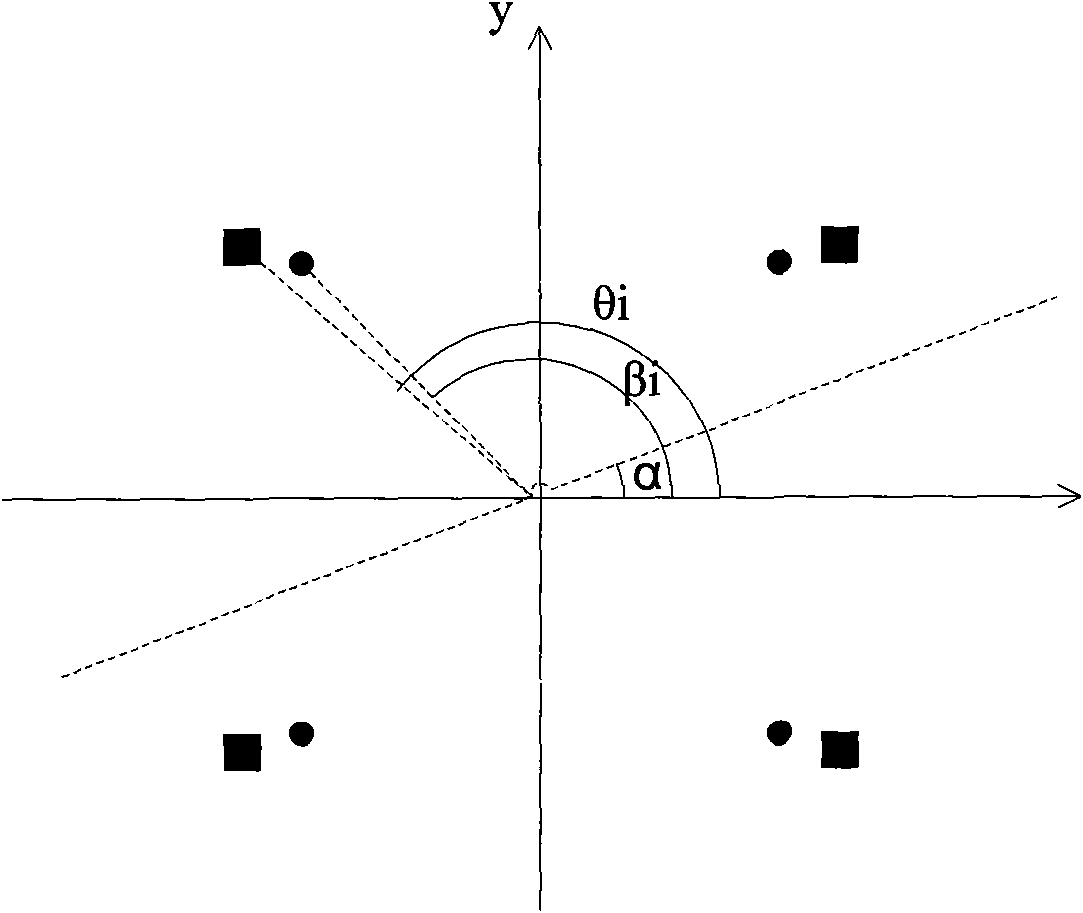

[0063] A programmable logic device and a microprocessor ARM module are used to receive the optical signal, and the coordinates of the initial spot position are set as (x i ,y i ), the distance to the center of the circle is R i , the angle between the line connecting the origin of the coordinates and the x-axis is β i ; The coordinates of the spot position after putting in the lens are (x i ,y i ), the distance to the center of the circle is r i , the angle between the line connecting the origin of the coordinates and the x-axis is θ i . The included angle between the baseline of the astigmatism and the x-axis is α, and the coordinates of converting the above two points into the coordinate sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com