System for automatically measuring charge distribution on surface of solid medium

A surface charge and automatic measurement technology, which is applied in the direction of measuring devices, measuring electrical variables, and testing dielectric strength, etc., can solve the problems that the surface charge distribution of solid insulating materials cannot be automatically measured and affects the miniaturization of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

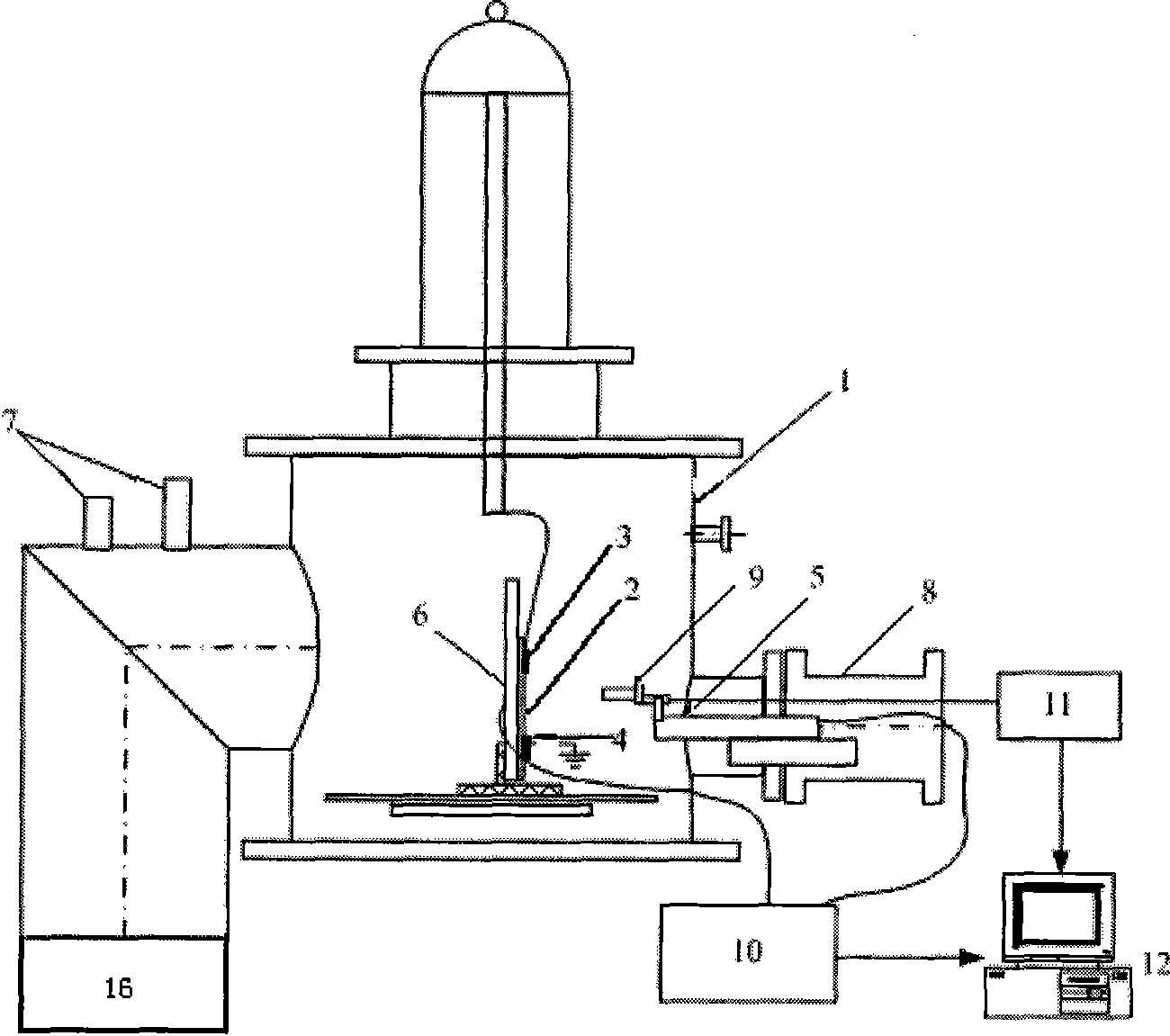

[0020] refer to figure 1 As shown, the system of the present invention includes a stainless steel airtight cavity 1, inside the stainless steel airtight cavity 1 there is an electrostatic capacitance probe 9 arranged on a one-dimensional displacement workbench 5 and a test product 2 fixed on a two-dimensional workbench 6 , A high-voltage electrode 3 and a ground electrode 4 are connected to both ends of the tested product 2 . The one-dimensional displacement table 5 and the electrostatic capacitance probe 9 are arranged in the stainless steel extension cavity 8 of the stainless steel airtight cavity 1 . The air pressure in the stainless steel airtight cavity 1 can be measured by the vacuum gauge 7 arranged on the airtight cavity. On the connecting pipeline of the body 1; the one-dimensional displacement workbench 5 and the two-dimensional workbench 6 are connected to the displacement stage control box 10 through control lines, and the output voltage signal of the electrostati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com