Holographic dealuminized composite film material and anti-counterfeiting object

A composite film and dealumination technology, which is applied in the field of anti-counterfeiting and valuable items, can solve the problems of being difficult to apply high-end anti-counterfeiting, limiting the scope of application of holographic films, and single anti-counterfeiting means, so as to retain the effect of holographic patterns and improve the anti-counterfeiting effect , improve the effect of visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Figure 2(A) is a common logo after dealumination. Since the film after dealumination is transparent, it is easily affected by the color of the substrate after it is attached to paper or card.

[0034] Fig. 2 (B) and Fig. 2 (C) are respectively the embodiment provided by the present invention, that is, after completing the fine dealumination, the mark made of the electromagnetic functional layer is plated, and the intrinsic metal color of the electromagnetic functional layer itself makes the fine dealumination layer It is more obvious in appearance, easy for the public to identify with naked eyes, and will not destroy the original holographic effect. Since the difference in reflectivity enhances the contrast of the pattern, the details of the fine dealuminated pattern are easier to recognize, such as the letters or numbers on the edge of the fine dealuminated pattern; Figure 2 (C) is a more complex improvement scheme, through the holographic layer. It is realized by part...

Embodiment 2

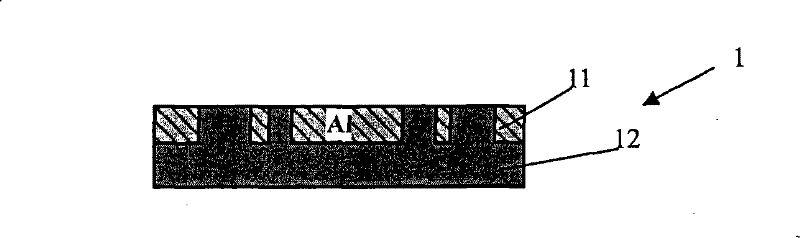

[0036] Hot stamping anti-counterfeiting labels such as image 3 In the composite structure shown in the figure, a peeling layer 2, a protective layer 3, and a holographic molding layer 4 are sequentially coated on the PET white film (on which a holographic pattern is molded and transferred). Sputtering winding coating process or vacuum evaporation prepare metal or alloy electromagnetic anti-counterfeiting functional layer 12 (such as the amorphous film in the embodiment of CN 200710122026.3 specification) on the hollow aluminum layer 11, and finally coat the hot melt adhesive bonding layer 5 to become Hot stamping anti-counterfeiting label.

[0037] During application, use the hot stamping head to press the label to a certain position on the substrate or the substrate in the direction of the arrow, and tear off the PET film through the peeling layer 2 to complete the hot stamping. The anti-counterfeiting pattern seen at this time can be, for example, Fig. 2 (B) or Fig. 2 (C),...

Embodiment 3

[0039] self-adhesive stickers such as Figure 4 The illustrated composite film material of the present invention is a self-adhesive composite structure layer, and a peeling layer 2 and a holographic molding layer 3 are sequentially coated on the PET white film (the molded transfer has a holographic pattern on it), and finely stripped after aluminum plating. Aluminum treatment, then use magnetron sputtering winding coating process or vacuum evaporation to prepare metal or alloy electromagnetic anti-counterfeiting functional layer 12 (for example, the amorphous film in the embodiment of CN 200710122026.3 specification) on the hollow aluminum layer 11, and finally coat The adhesive layer 5 and the backing paper 7 coated with the silicone resin coating 6 become the self-adhesive label of the present invention. Same as the usual self-adhesive labels, the bonding fastness between the peeling layer 2 and the PET is stronger than that of the above-mentioned hot stamping film. Therefo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com