Temperature-controllable solvent vapor pressure gradiometer

A gradient meter and vapor pressure technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of difficult to control the mixing ratio for a long time, difficult to control the temperature of the system, and serious air pollution. , to achieve the effect of stable solvent vapor gradient, simple and reasonable structure, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

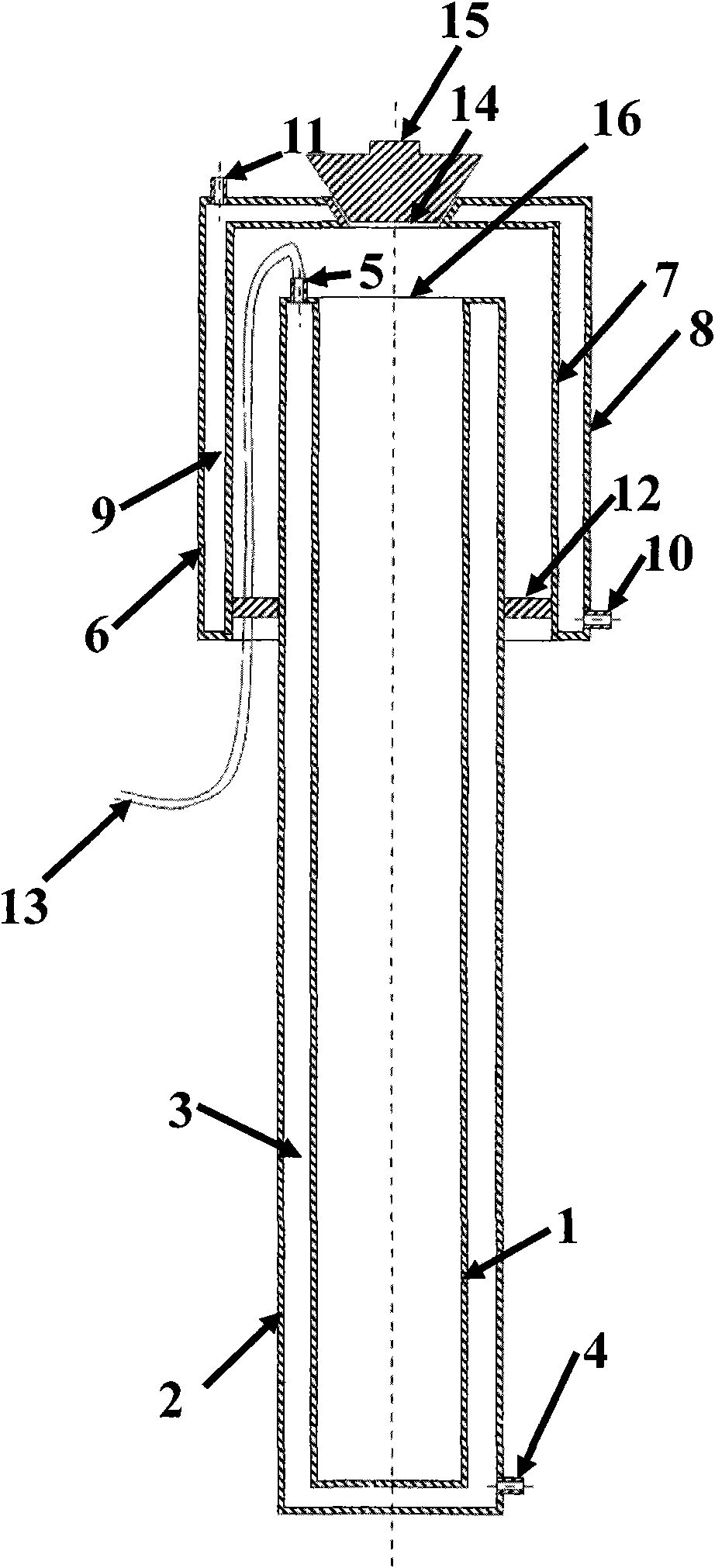

[0021] Such as figure 1 As shown, the composition of the solvent vapor pressure gradiometer includes: a vertically placed circular solvent diffusion tube 1 is placed inside a circular temperature control cylinder 2, and the centers of the two are aligned; the bottom of the diffusion tube 1 and the temperature control cylinder There is a gap in the lower part of 2, and the upper edge of the solvent diffusion tube 1 and the upper edge of the temperature control cylinder 2 are airtightly sealed on the upper surface of the ring to form a ring-shaped columnar solvent diffusion control chamber 3; the solvent diffusion The gap left between the lower part of the tube 1 and the lower part of the temperature control cylinder 2 communicates with the temperature control cavity 3 of the solvent diffusion tube, and the temperature control liquid of the solvent diffusion tube 1 flows through the temperature control cavity 3 of the solvent diffusion tube and the lower part of the solvent diffu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com