Double support pipe cutting equipment

A technology of pipe cutting equipment and double supports, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of low processing efficiency, high installation accuracy requirements, and affecting processing quality, and achieve high processing accuracy and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

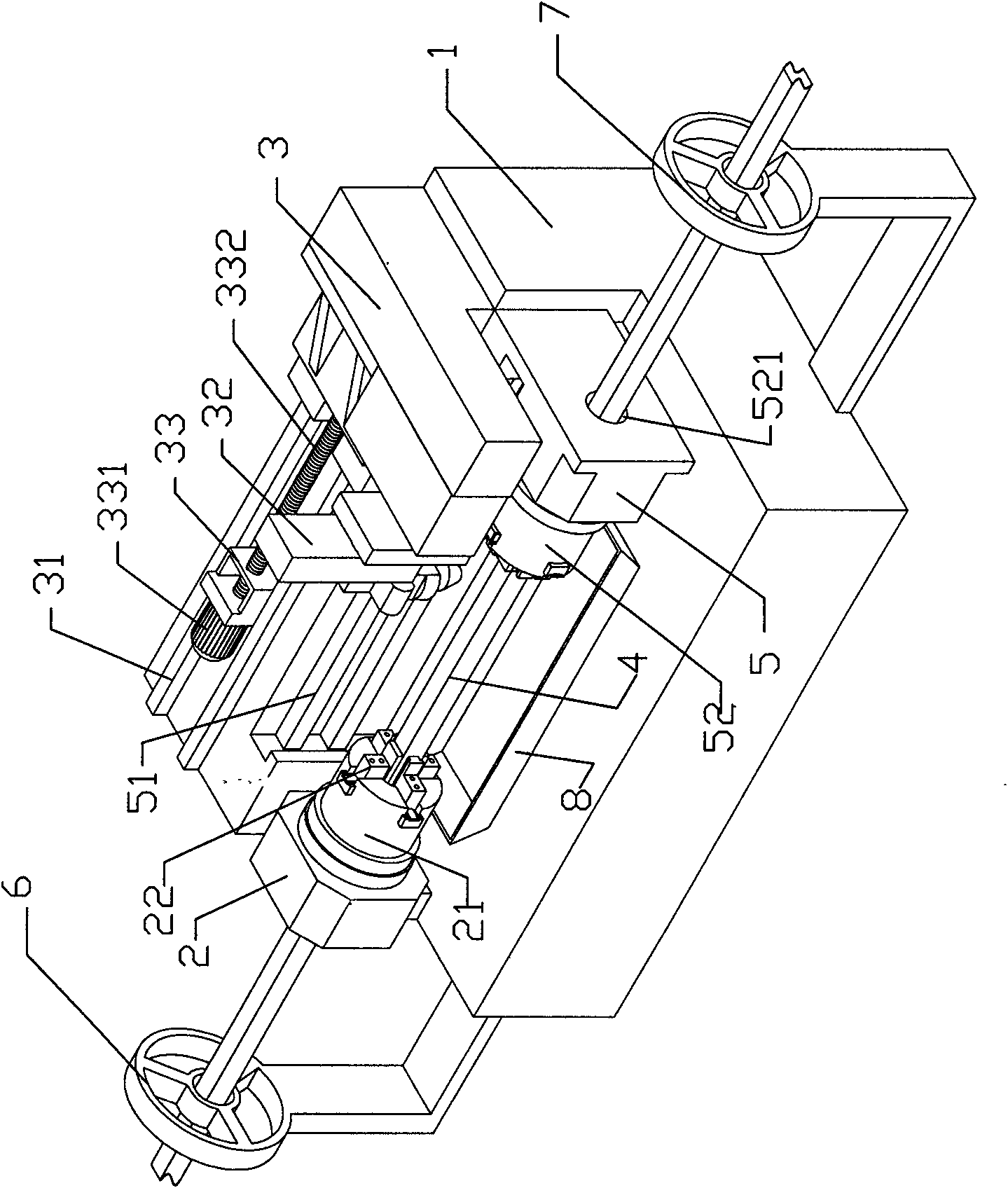

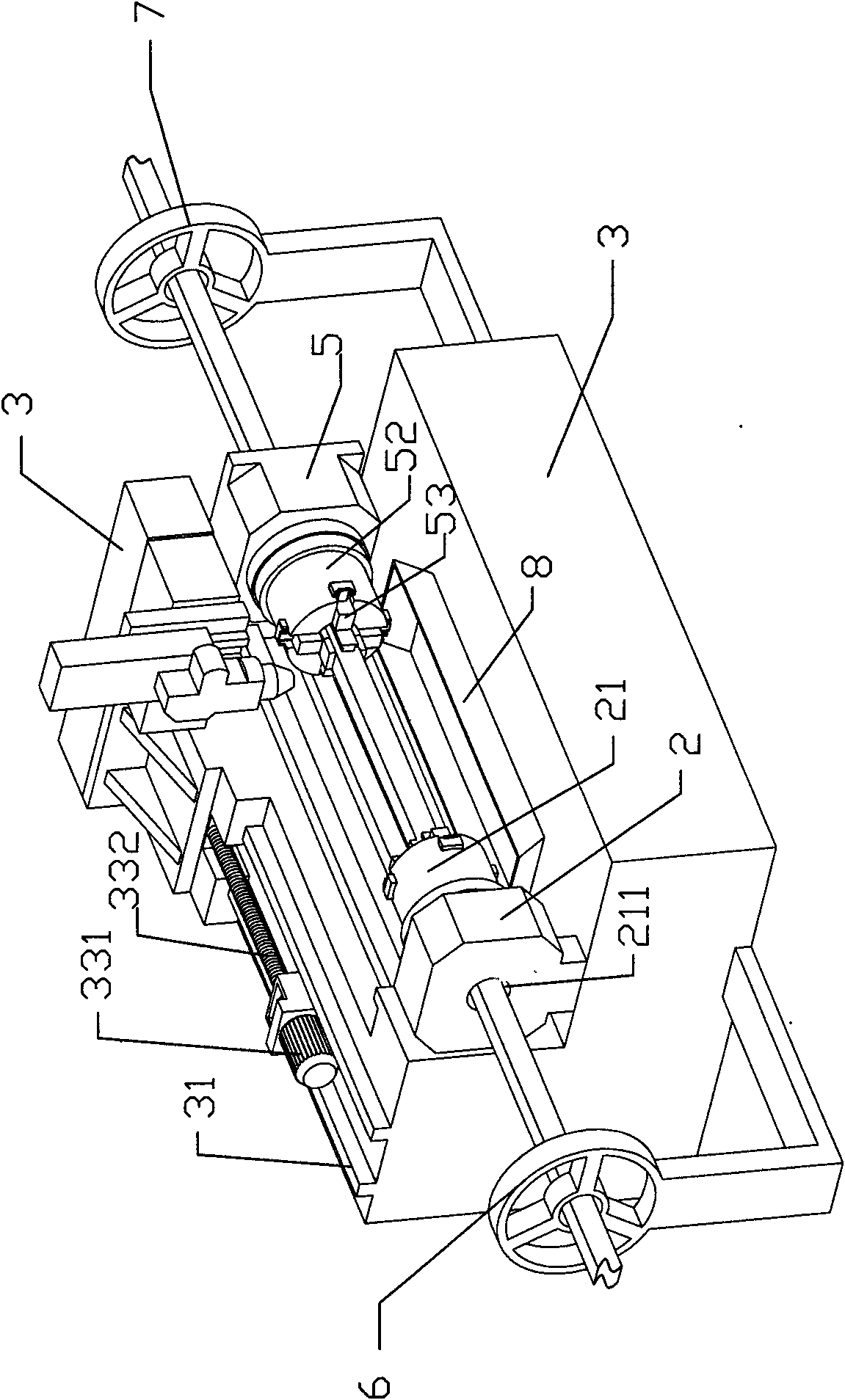

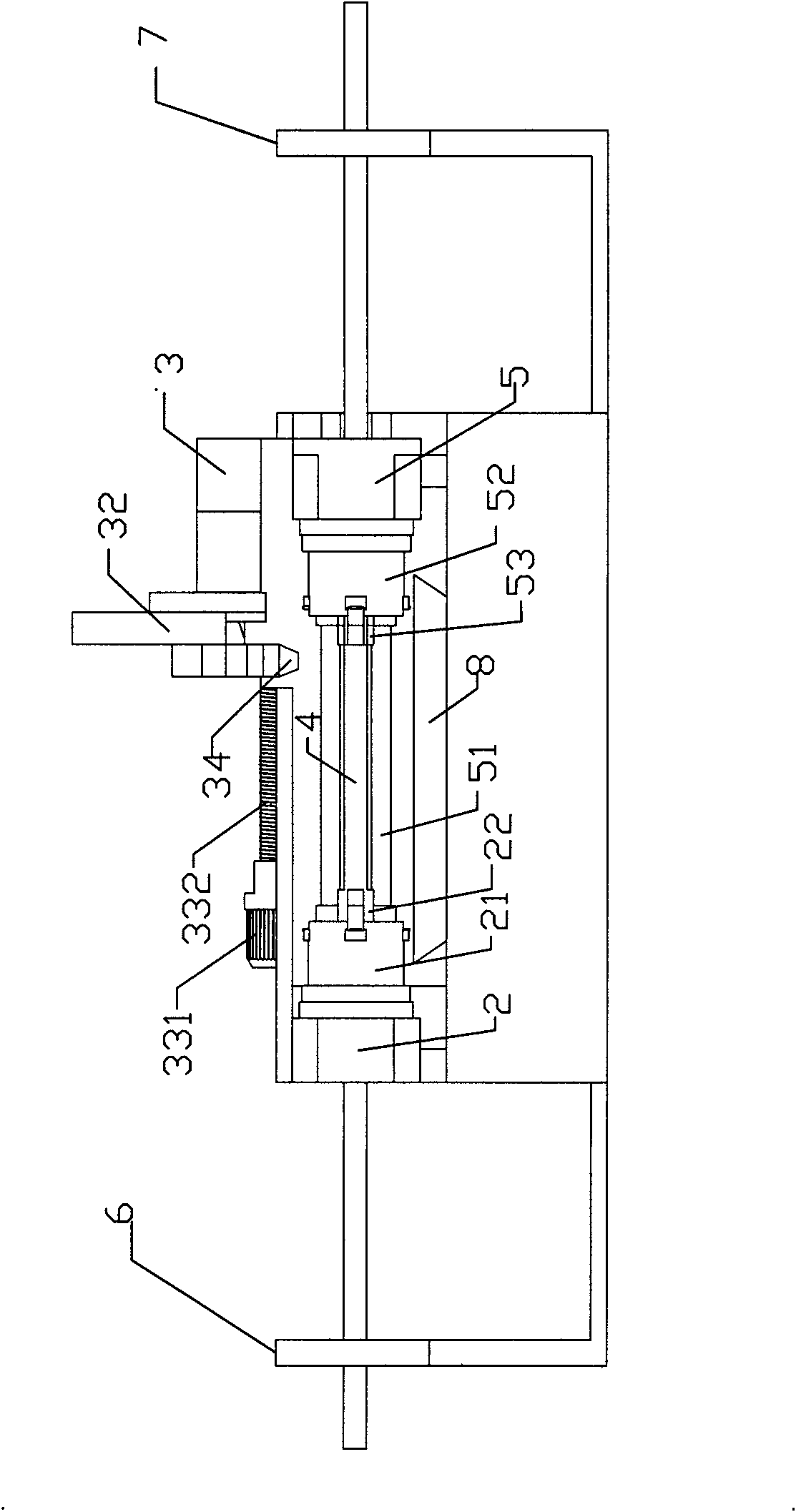

[0025] With reference to accompanying drawing, further illustrate the present invention:

[0026] The double-support pipe cutting equipment includes a frame 1, and the frame 1 is provided with a support mechanism 2 for receiving incoming pipe materials and a cutting mechanism 3 for slitting and processing the pipe 4;

[0027] The support mechanism 2 includes a first support seat 21 fixed on the frame 1 and a first clamp 22 for clamping pipes;

[0028] Described cutting mechanism comprises the cutting guide rail 31 that is fixed on the frame, the cutting support 32 that is slidably installed on the cutting guide rail 31, and the pushing mechanism 33 that promotes cutting support 32 sliding; Described cutting support 32 is equipped with A laser cutting head 34 positioned directly above the pipe material 4;

[0029] The double-support pipe cutting equipment also includes a feeding mechanism 5, and the feeding mechanism 5 includes a feeding guide rail 51 fixed on the machine tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com