Mems probe fabrication on a reusable substrate for probe card application

A technology of micro-electromechanical and probe card, applied in the field of micro-electromechanical, can solve the problems of unevenness, uneven outline, lack of smooth transition and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

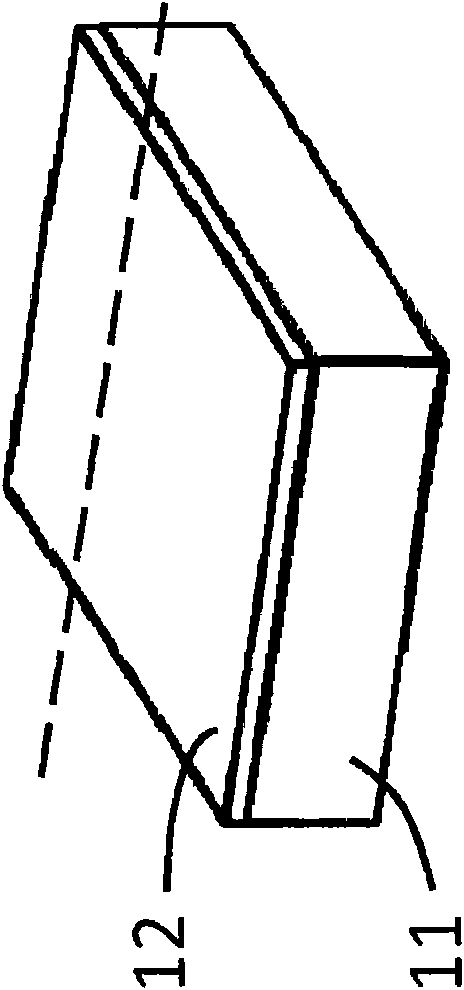

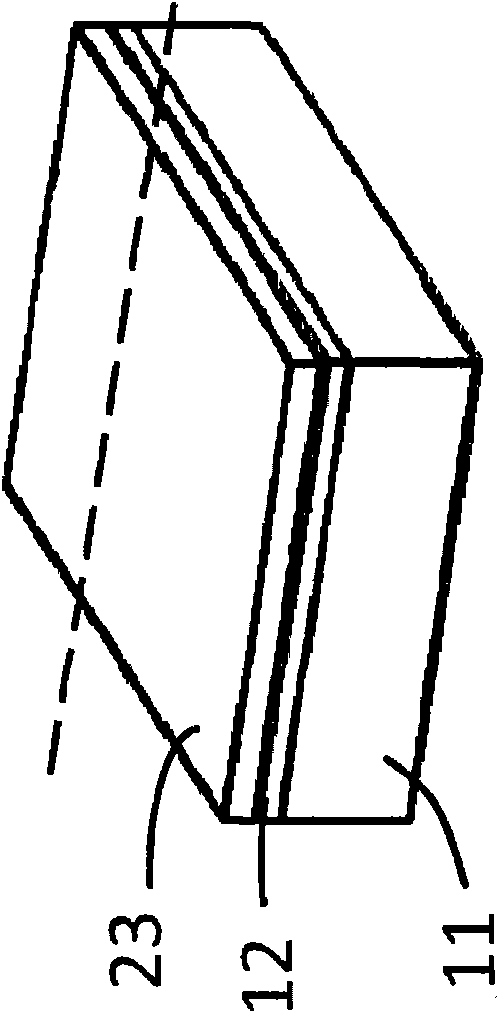

Image

Examples

Embodiment Construction

[0029] In the description below, numerous details are set forth. However, it will be readily understood by those skilled in the art that the present invention may be practiced without these specific details. In some instances, well-known structures and devices are shown in block diagram form rather than in specific detail in order to avoid obscuring the present invention.

[0030] The term "MEMS probe" herein refers to a probe made by microelectromechanical technology. It should be understood that the techniques described herein can also be applied to other MEMS components (such as mechanical components, optical components, electrical components, etc.). Typically, the dimensions of MEMS parts range from 10×10×10 microns to 5000×5000×5000 microns. Examples of MEMS components include a probe, a laser module, optical lenses, microgears, microresistors, microcapacitors, microinductors, microdiaphragms, microrelays, microsprings, waveguides, microgrooves, and the like.

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com