Extrusion device for rigid polyvinyl chloride sheets used for packaging

A technology of rigid polyvinyl chloride and extrusion equipment, which is applied in the field of chemical sheet extrusion molding processing equipment, which can solve the problems of large surface temperature difference, flow lines, cooling and solidification of the sheet surface, etc., and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

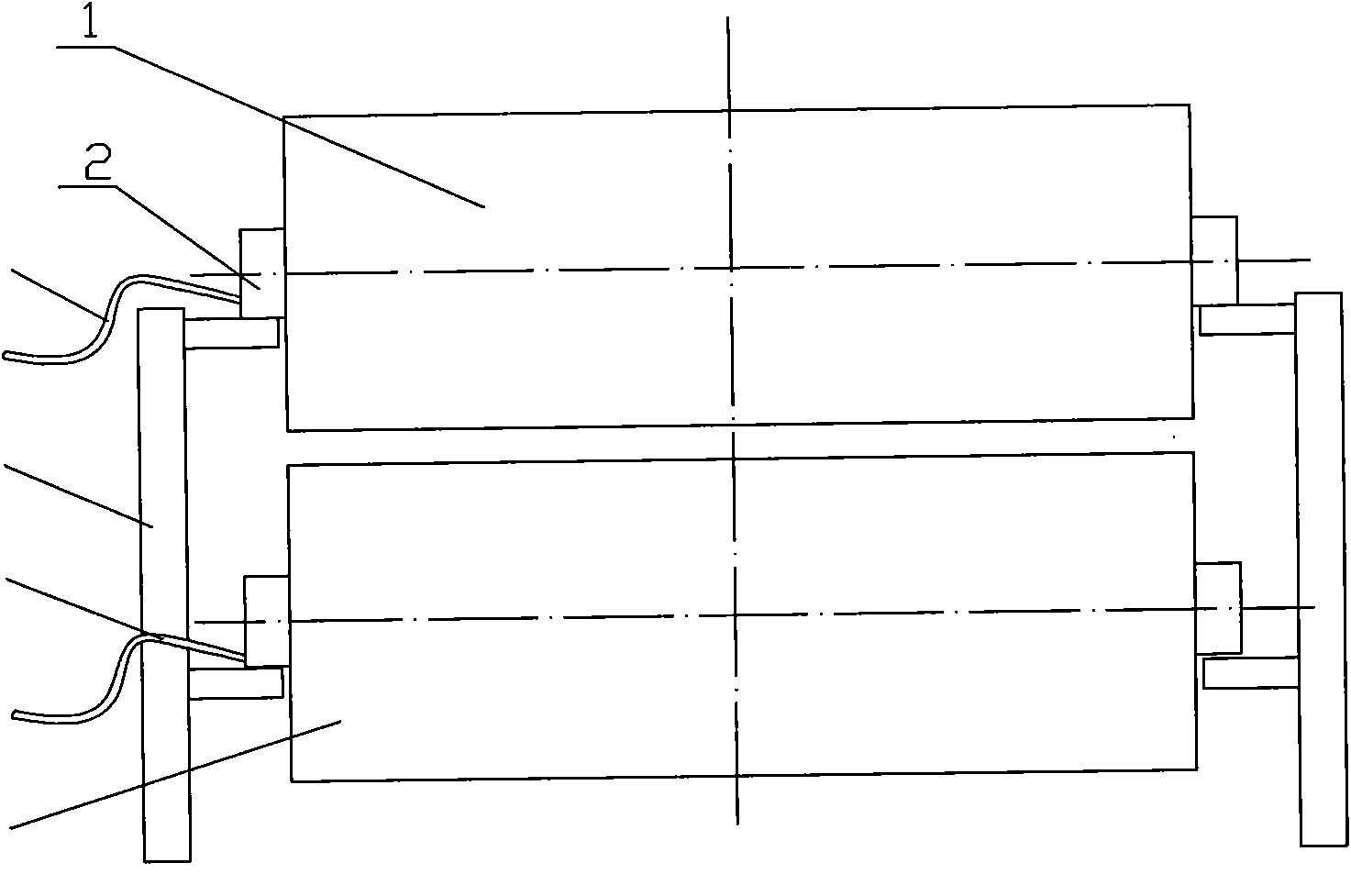

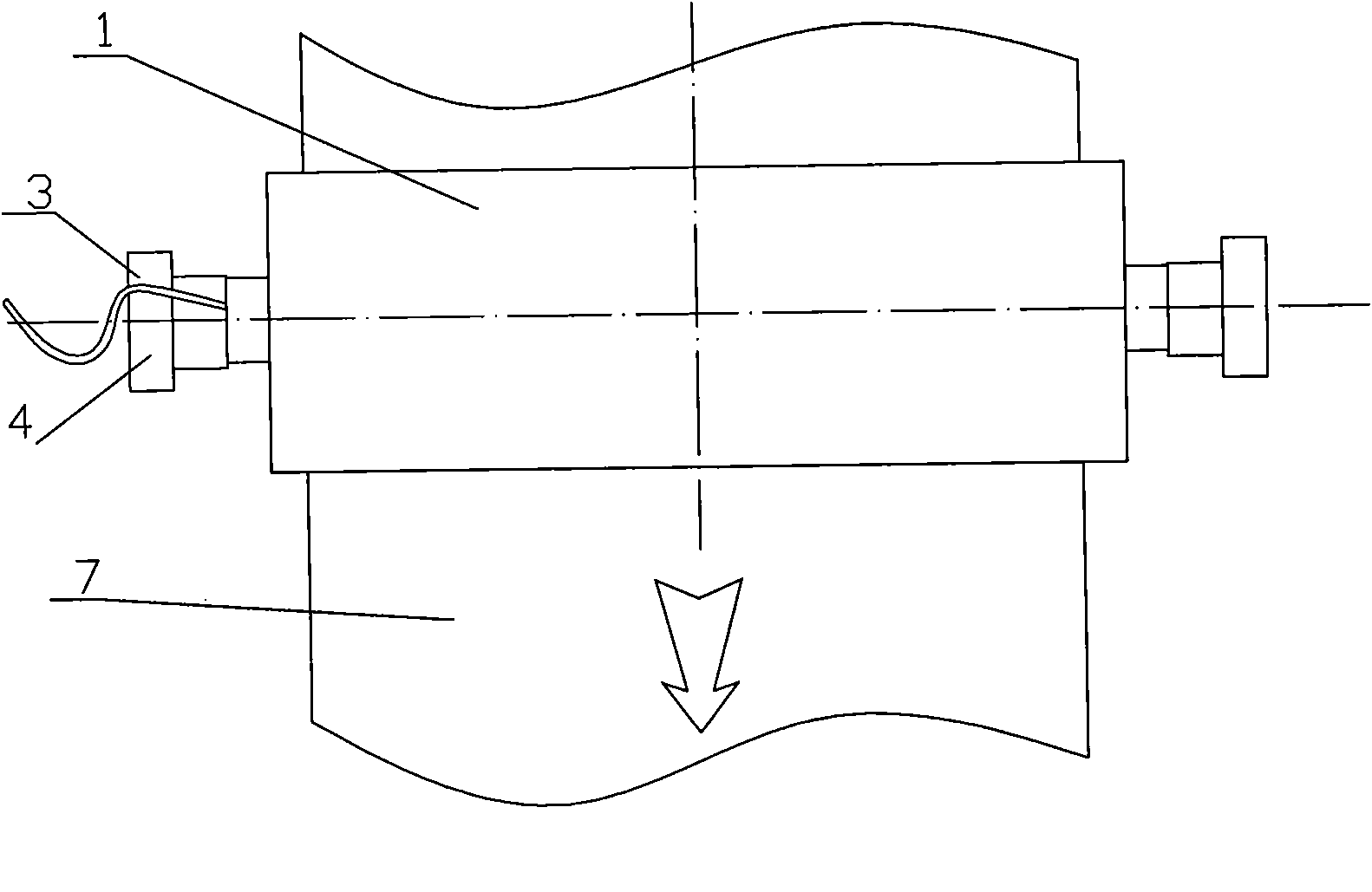

[0014] The present invention as figure 1 , 2 Shown, comprise frame 4, upper pressing roller 1, lower pressing roller 6, are respectively provided with the heating device that makes it can heat up and keep temperature on upper pressing roller 1, lower pressing roller 6. The heating device adopts an electric heater, and electric heaters are respectively arranged inside the upper pressing roller 1 and the lower pressing roller 6, and the electric heaters can be respectively supplied to each electric heater through the upper pressing roller heating device brush wire 3 and the lower pressing roller heating device brush wire 5. The heater is powered.

[0015] In order to overcome the deflection and deformation of the pressure rollers during extrusion, the upper pressure roller 1 and the lower pressure roller 6 deflect 0.5 to 5° on the horizontal plane relative to the centerline of their respective axes, and the upper pressure roller 1 and the lower pressure roller 6 deflect in opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com