Force balance type electric cylinder featuring fluid circulation

A technology of fluid circulation and force balance, applied in the direction of fluid pressure actuation devices, etc., can solve the problems of waste of resource costs, unbalanced positive and negative torque output of electric cylinder motors, etc., achieve cost reduction, increase work reliability, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

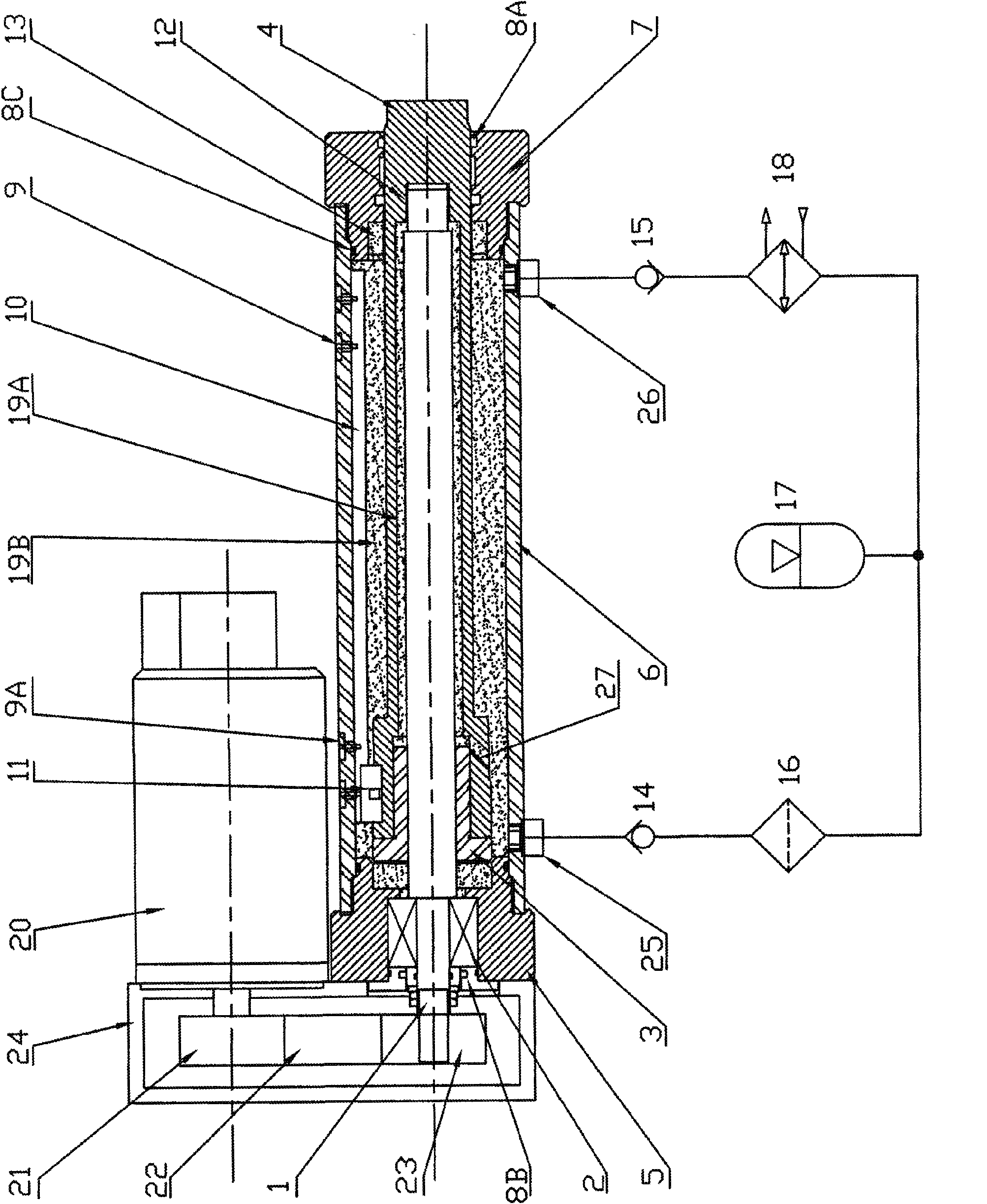

[0016] The force balance fluid circulation electric cylinder of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] A force-balanced fluid circulation electric cylinder, including a machine base 24, a motor 20, a motor synchronous wheel 21, a synchronous belt 22, a screw synchronous wheel 23, a bearing 2, a screw 1, a screw nut 3, an oil cylinder body 19, and an oil cylinder The body 19 includes a cylinder 6 and a piston rod 4 that can move back and forth in the cylinder 6. The front and rear ends of the oil cylinder 19 are respectively provided with a front end cover 7 and a rear end cover 5. The screw rod 1 is supported and installed on the rear end cover 5 through a rolling bearing 2. , the screw nut 3 is rigidly connected to the piston rod 4, the first oil chamber 19A is formed between the screw 1 and the piston rod 4, and the second oil chamber 19A is formed between the cylinder barrel 6 of the oil cylinder block 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com