Drying method of lead-acid storage battery plate

A technology of lead-acid batteries and pole plates, which is applied in the direction of lead-acid battery electrodes, drying, dryers, etc., can solve the problems of time-consuming and energy-consuming costs, shorten drying time, facilitate popularization and application, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

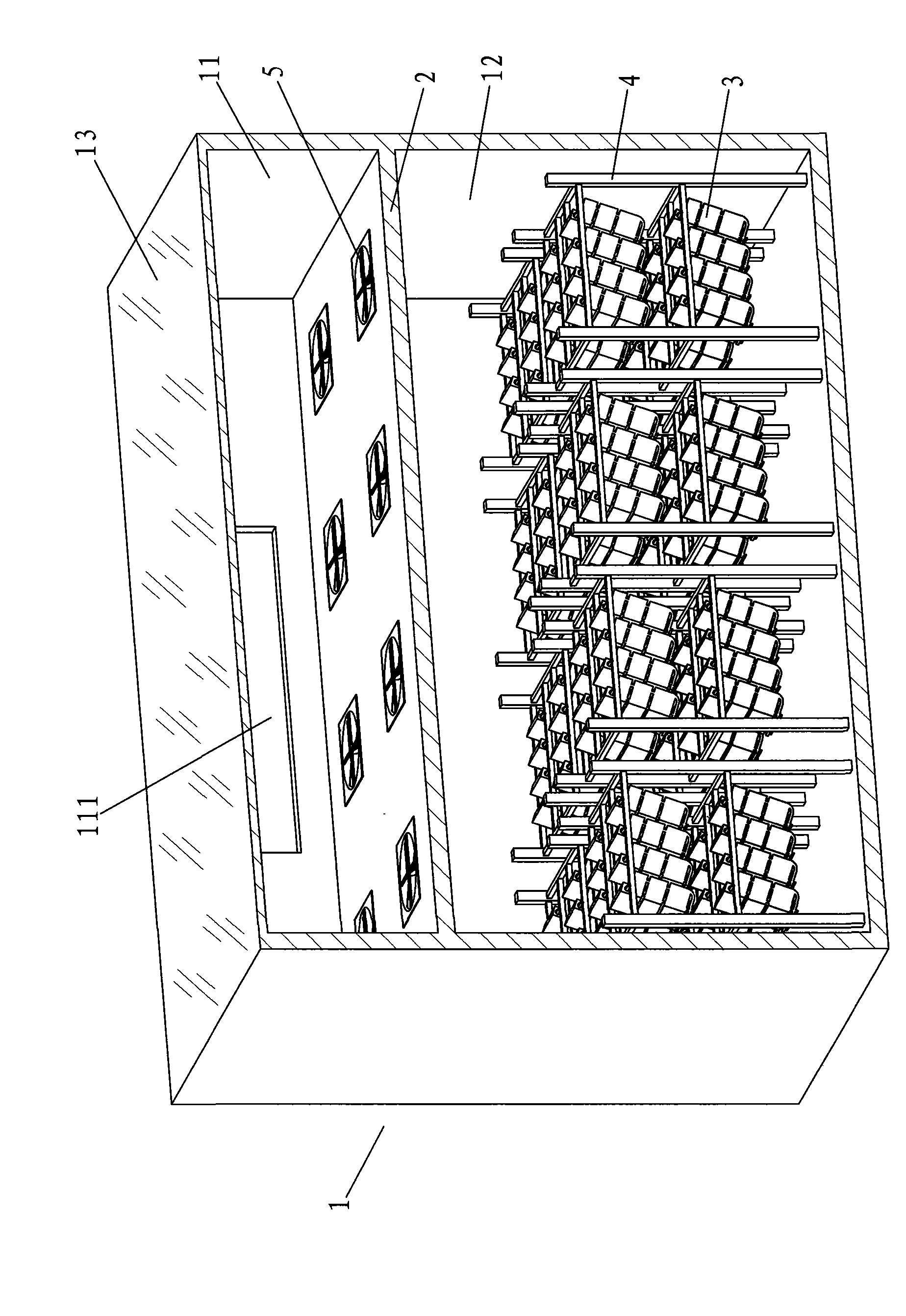

[0010] A kind of drying method of lead-acid battery pole plate of the present invention, as figure 1 As shown, taking the drying room 1 of 2.5 meters * 4.8 meters as an example, the drying room 1 is divided into an upper layer 11 and a lower layer 12 through a partition 2. The height of the upper layer 11 is 1-2 meters, and the upper layer 11 is provided with an air inlet. 111, an induced draft fan can be installed in the air inlet 111, the height of the lower layer 12 is about 2.5 meters, and the roof 13 of the drying chamber is designed as a light-transmitting roof, and the pole plate 3 is suspended on the lower layer of the drying chamber through the iron frame 4 12. There are air outlets on the partition 2 corresponding to the top of each iron frame 4, and each air outlet is respectively equipped with an axial flow blower 5 with a power of about 1KW, and each axial flow blower 5 is respectively blown to each iron frame 4 .

[0011] Wherein, the roof 13 can be made of glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com