Wind-spring type expandable sampling rod

A technology of sampling rod and coil spring, which is applied in the direction of sampling device, etc., can solve the problems of large space occupation, small working stroke, failure of sampling rod, etc., and achieve the effect of increasing area, expanding stroke, reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

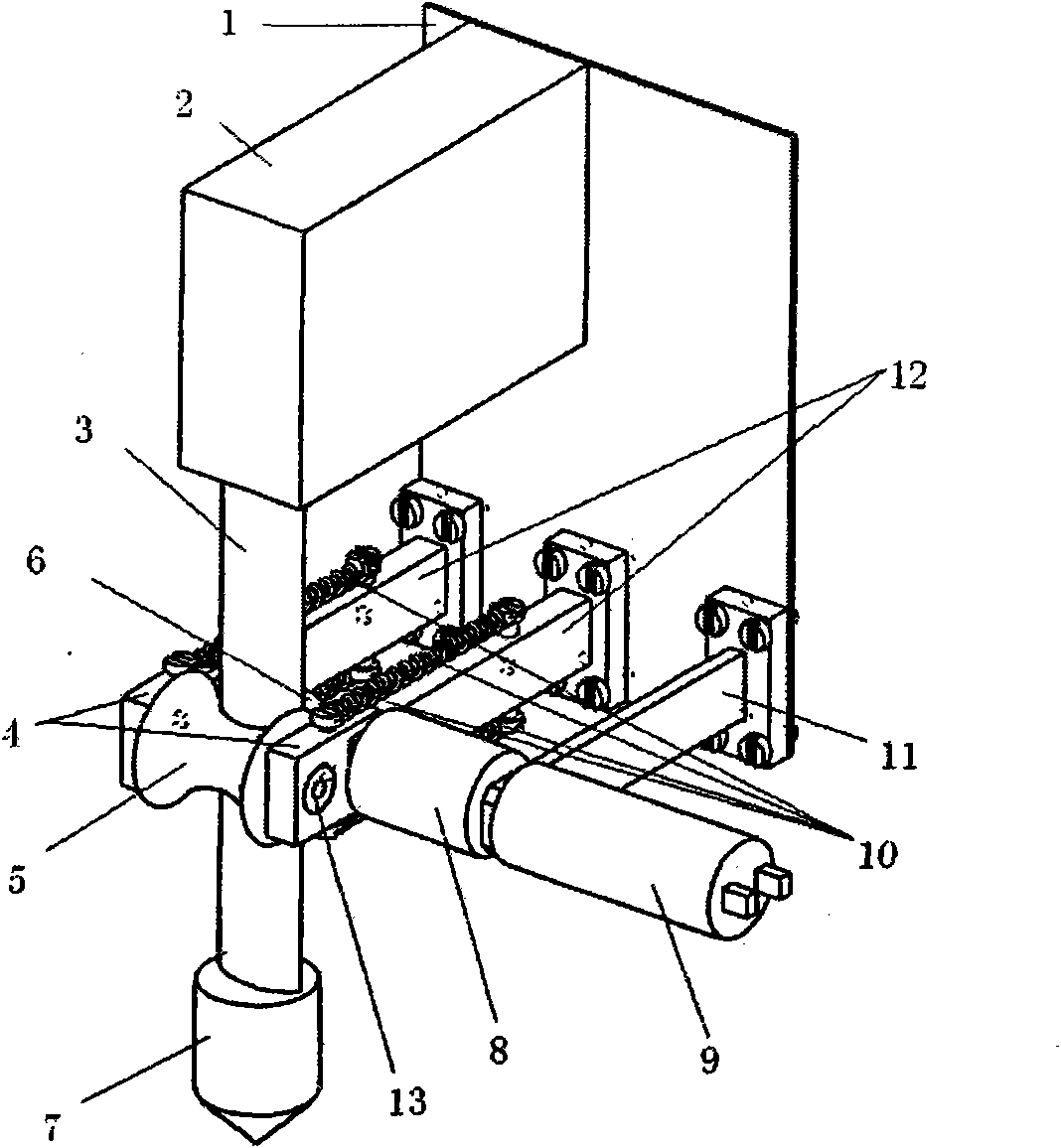

Embodiment 1

[0013] This embodiment relates to a coil spring type retractable sampling rod device with small volume and large stroke. The coil spring contraction box 2, the roller bracket 12 and the motor bracket 11 are all fixed on the fixed plate 1, and the motor 9 is fixed on the motor bracket 11 and connected with it. The coupling 8 is coaxially connected, and the coupling 8 is coaxially connected with the convex roller 6. The convex roller 6 is fixed on the roller bracket 12 through the bearing 13, and the concave roller 5 is connected with the two concave roller brackets 4 through the bearing 13. The concave roller The bracket 4 is fixed on the roller bracket 12 through the tension spring 10. The elastic rod 3 with a cross-sectional area of "C" is clamped by the convex roller 6 and the concave roller 5. The lower end of the elastic rod 3 is connected to the sampling head 7. When the motor 9 is forward When rotating, the motor drives the convex roller 6 to rotate in the forward direc...

Embodiment 2

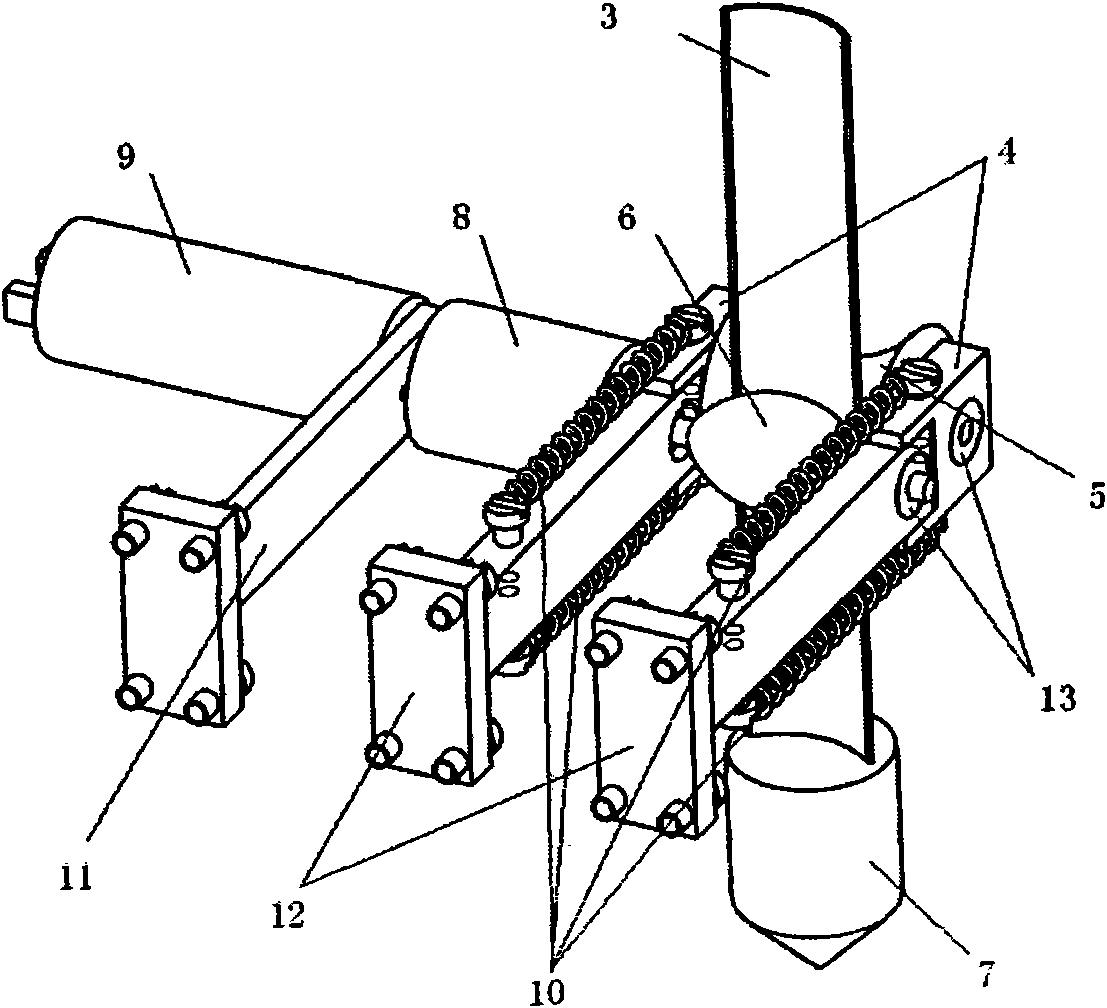

[0015] This embodiment relates to a coil spring type retractable sampling rod device with small volume and large stroke. The coil spring contraction box 2, the roller bracket 12 and the motor bracket 11 are all fixed on the fixed plate 1, and the motor 9 is fixed on the motor bracket 11 and connected with it. The coupling 8 is coaxially connected, and the coupling 8 is coaxially connected with the convex roller 6. The convex roller 6 is fixed on the roller bracket 12 through the bearing 13, and the concave roller 5 is connected with the two concave roller brackets 4 through the bearing 13. The concave roller The bracket 4 is fixed to the roller bracket 12 through the tension spring 10, and the elastic rod 3 with a cross-sectional area of "C" is clamped by the convex roller 6 and the concave roller 5, and the elastic rod 3 is wound on the outside of the recovery wheel 14, shrinking the coil The inner end of the spring 16 is fixed in the opening of the cylinder 15 with the "one...

Embodiment 3

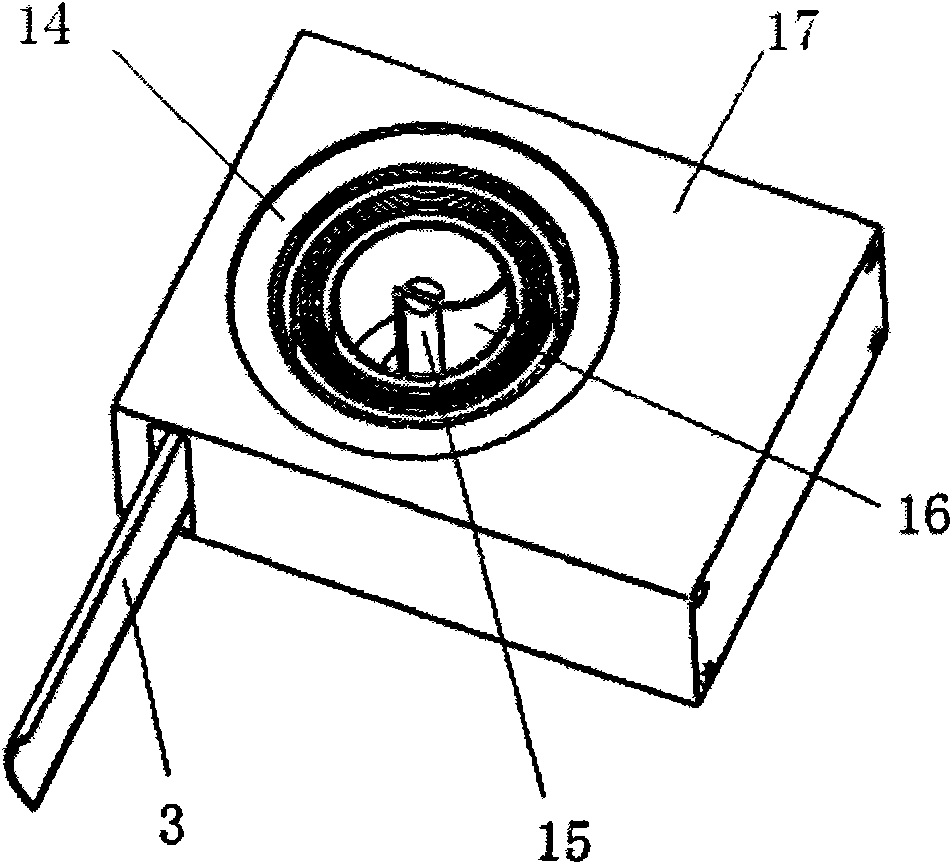

[0017] This embodiment relates to a coil spring retractable sampling rod, including: a bracket, on which a coil spring retractable box 2 and a motor 9 are arranged, and the coil spring retractable box 2 includes a housing 17 and a "C" shape in cross section The elastic rod 3 is provided with an inlet and outlet for the elastic rod 3 on the casing 17, and the recovery wheel 14 is connected with the rotation on the casing 17, and one end of the elastic rod 3 is connected with the recovery wheel 14, and on the rotating shaft of the motor 9 Convex roller 6 is connected and convex roller 6 is rotatably connected with the bracket, concave roller bracket 4 is slidably connected on the bracket, concave roller 5 matching with convex roller 6 is connected on concave roller bracket 4, and the other end of elastic rod 3 Clamped between the concave roller 5 and the convex roller 6, the sliding direction of the concave roller bracket 4 is parallel to the clamping force of the clamping elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com