Liquid processing apparatus, liquid processing method and storage medium

A liquid treatment and cup body technology, which can be used in devices that apply liquid to surfaces, semiconductor/solid-state device manufacturing, coating, etc., and can solve problems such as increasing the total exhaust volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

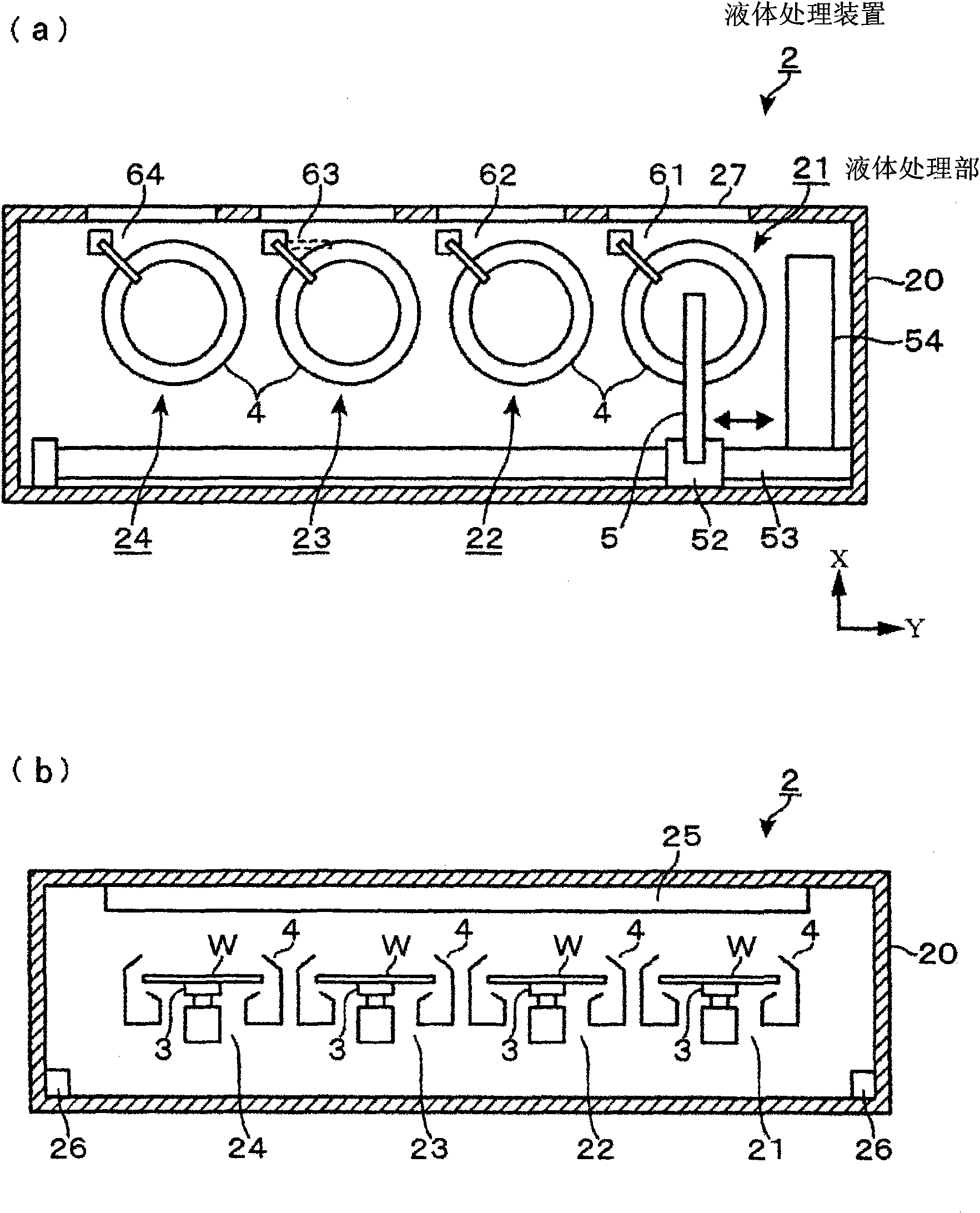

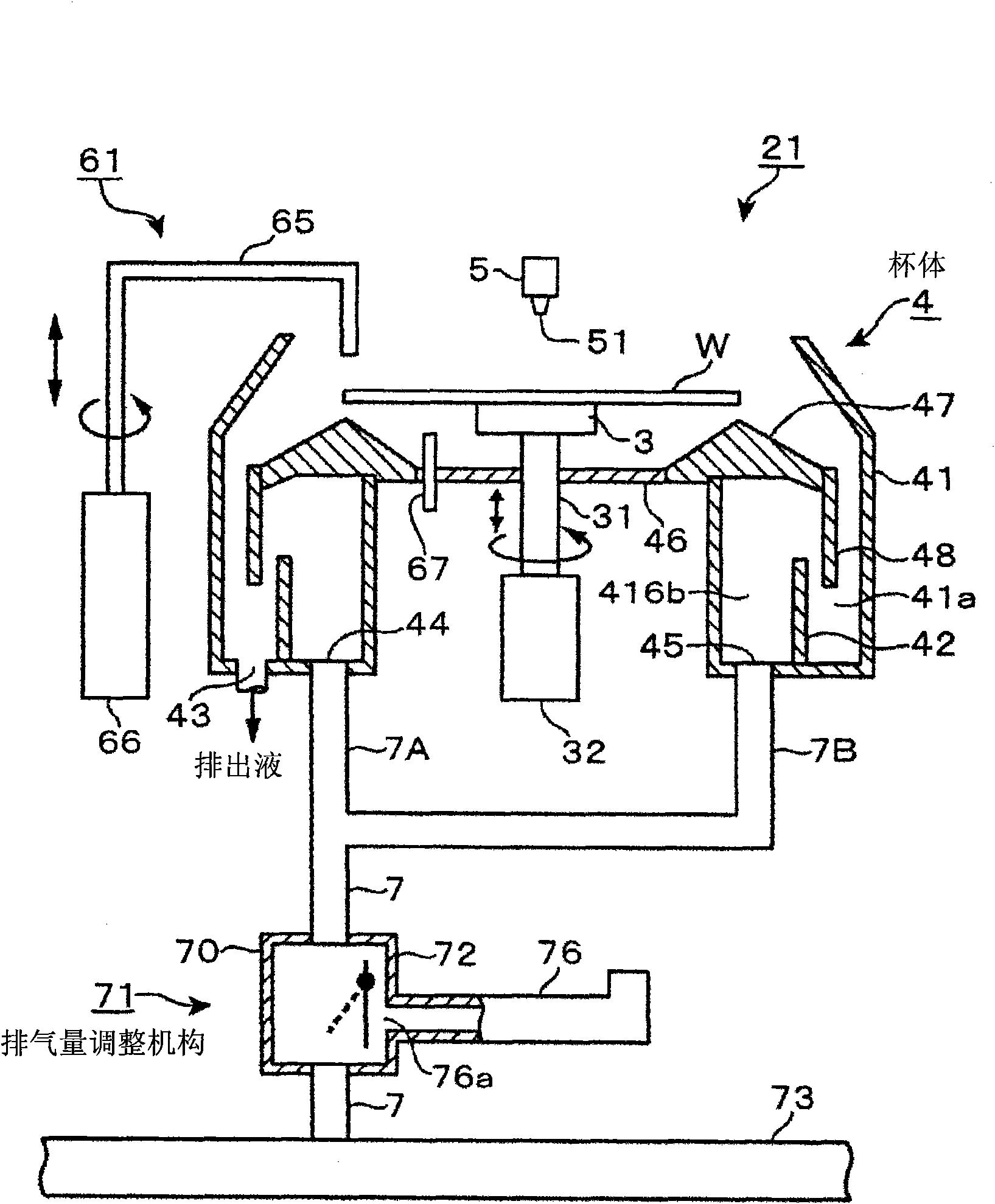

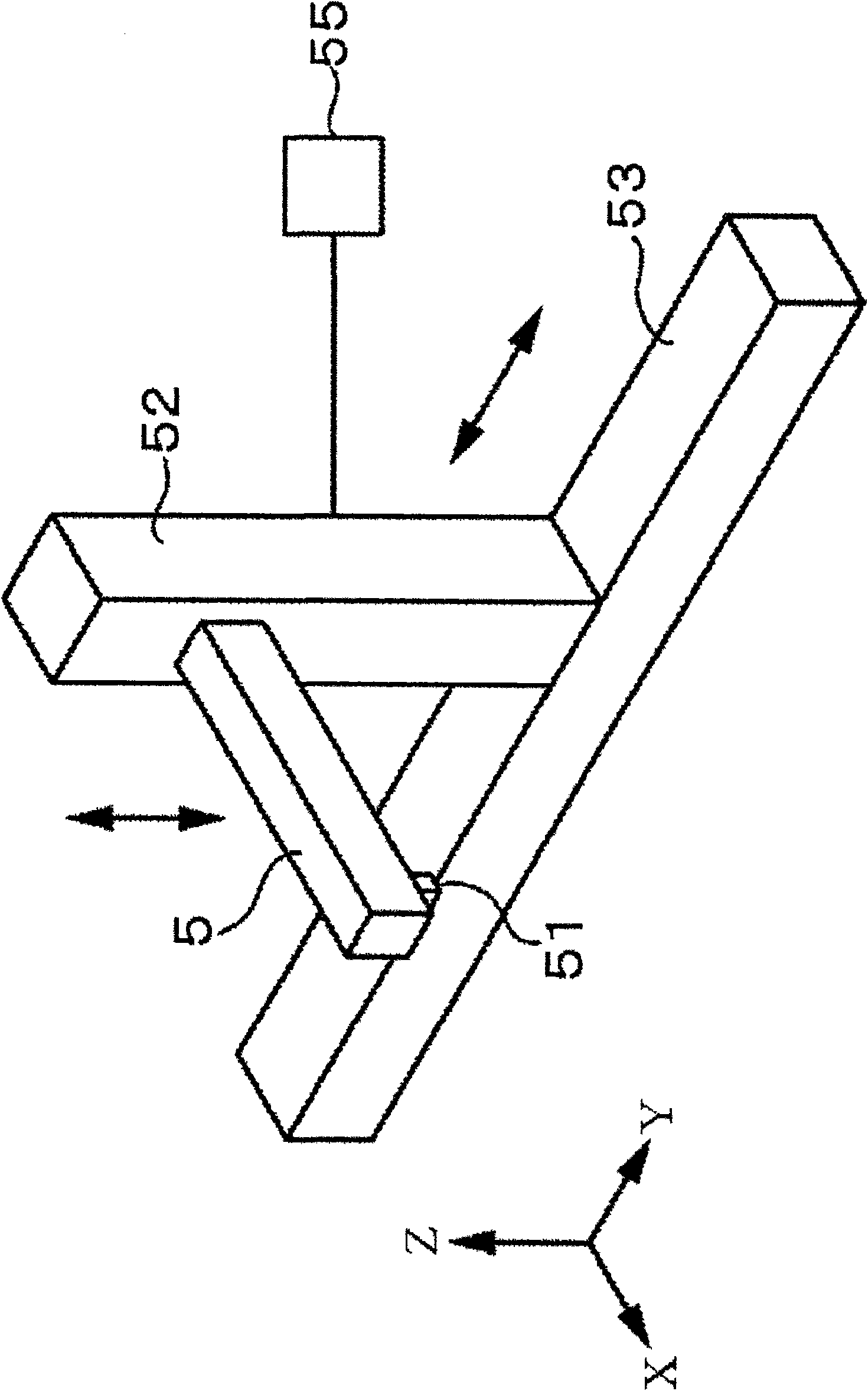

[0059] Hereinafter, according to an embodiment of the present invention, a case where the liquid processing apparatus of the present invention is applied to a coating apparatus for coating a resist liquid on a substrate such as a wafer W will be described as an example. figure 1 2 is the above-mentioned liquid processing device. In this liquid processing device 2, n (n is an integer greater than 3), in this example, 4 liquid processing units 21 to 24 are arranged in the horizontal direction (Y in the figure). Axial direction) in a state of being arranged side by side in a common frame 20. These liquid processing units 21-24 have the same structure, therefore, in figure 2 The liquid processing unit 21 is taken as an example for detailed description.

[0060] figure 2 Middle 3 is a spin chuck as a substrate holding portion for sucking and absorbing the central portion of the back side of the wafer W to keep it horizontal. The spin chuck 3 is connected to a drive mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com