Linear temperature sensing fire detector with point-shaped temperature sensing element and alarm method thereof

A technology of fire detectors and components, applied to fire alarms with electric effects, thermometers and thermometers with electric/magnetic components that are directly sensitive to heat, can solve the problem of failure to alarm normally, failure to report fire normally, and alarm reliability and sensitivity decline, to eliminate detection blind spots and improve alarm reliability and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

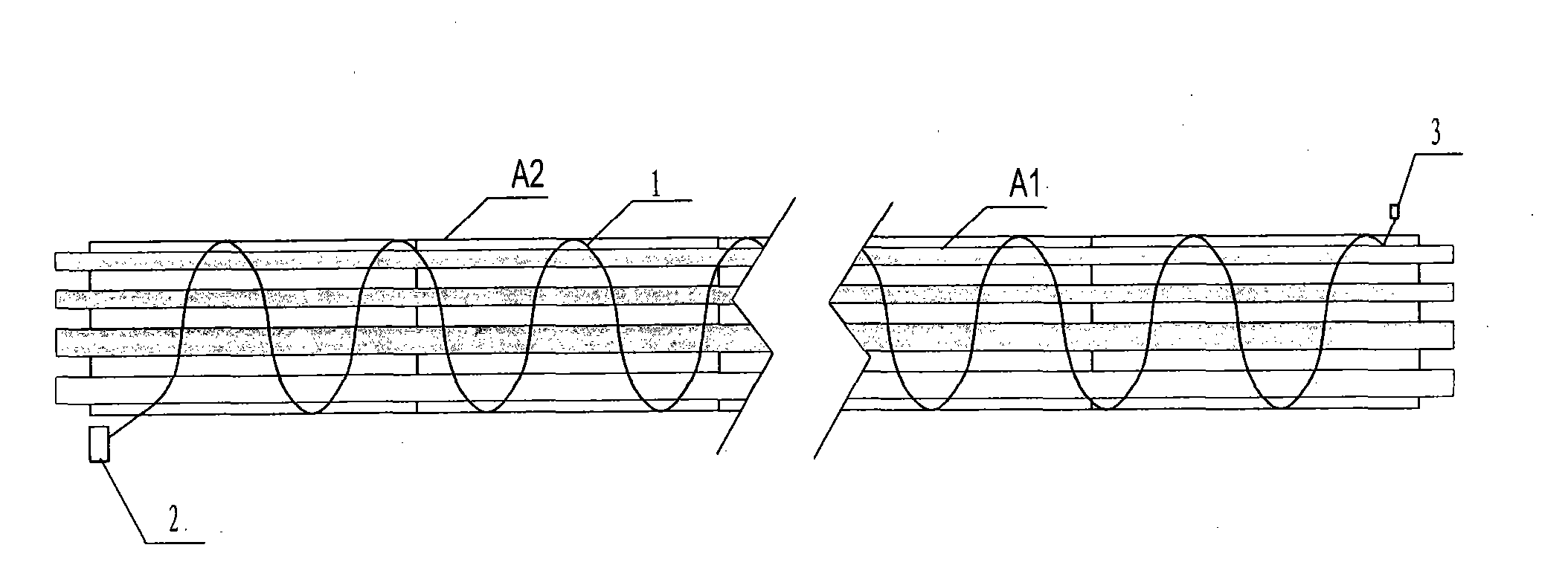

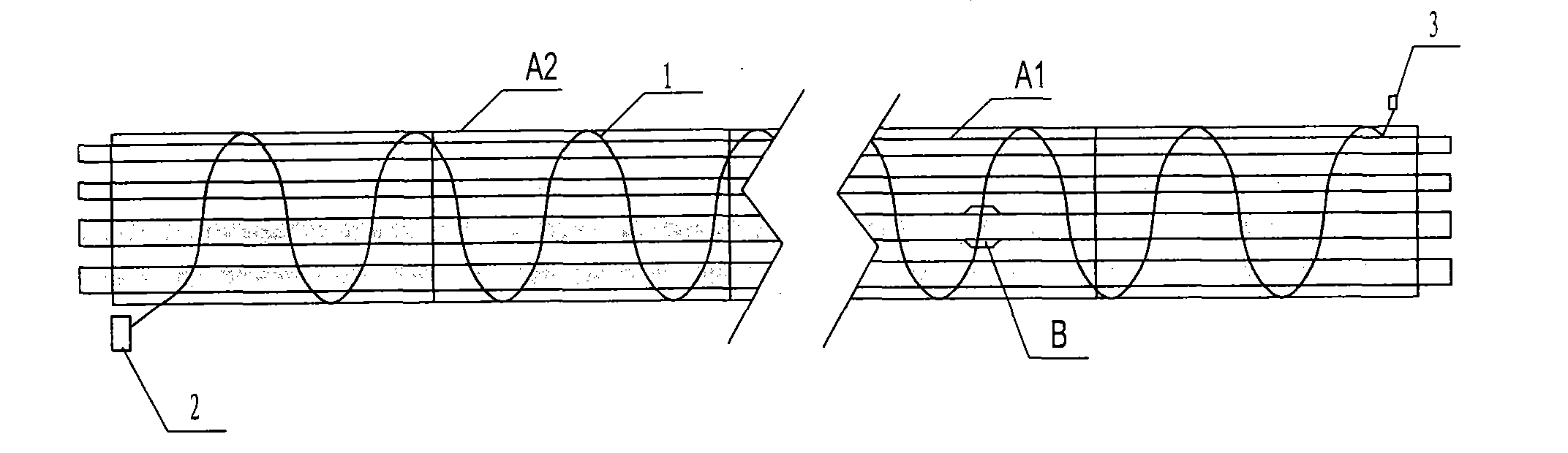

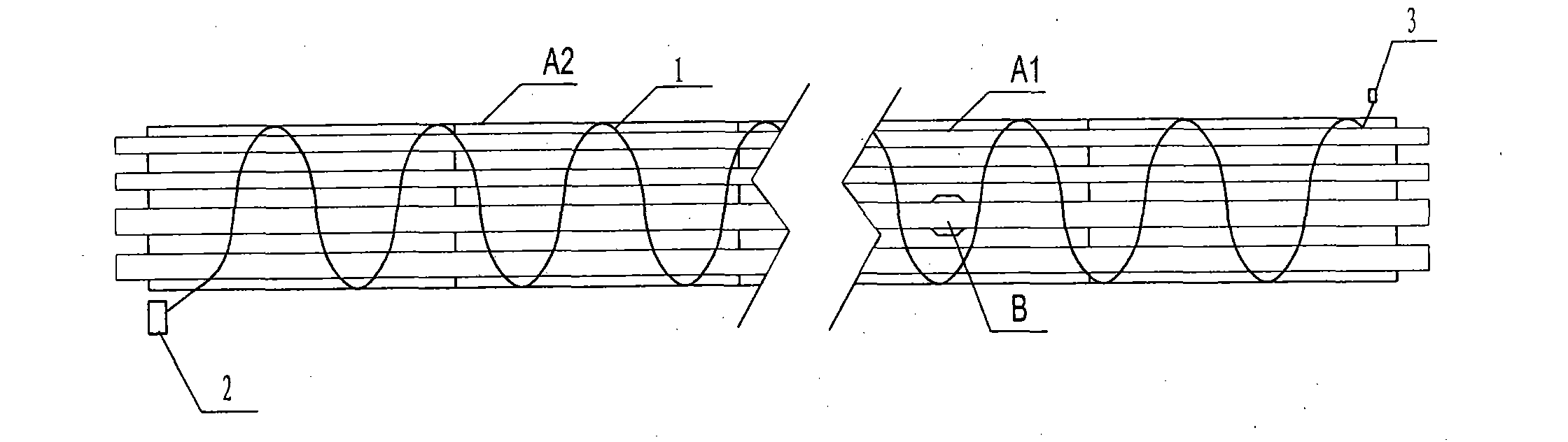

[0018] Such as Figure 4 As shown, the line-type temperature-sensing fire detector with a point-type temperature sensing element provided in this embodiment includes a line-type temperature sensing element 1, a conversion box 2 connected to both ends of the line-type temperature sensing element 1 and a terminal for circuit breakage monitoring. Resistor 3; wherein the linear temperature sensing element 1 includes two detection conductors arranged in parallel and an NTC characteristic barrier layer arranged in parallel between the two detection conductors; the linear temperature sensing fire detection with a point temperature sensing element The device also includes a point-type temperature sensing element 7 installed at the cable joint B and connected to the conversion box 2 through two conductors 8, and the conversion box 2 real-time temperature or Alarm electrical parameters (or sampled values) are detected.

[0019] In addition, whenever there is a cable joint B, a point-ty...

Embodiment 2

[0024] Such as Figure 4 As shown, the line-type temperature-sensing fire detector provided in this embodiment includes a line-type temperature-sensing element 1, a conversion box 2 respectively connected to both ends of the line-type temperature-sensing element 1, and a terminal for circuit breakage monitoring. Resistance 3; wherein the linear temperature sensing element 1 includes two detection conductors arranged in parallel and an NTC characteristic barrier layer and a meltable insulation layer arranged in parallel between the two detection conductors, and at least one of the two detection conductors is elastic Conductor or memory alloy wire; the line type temperature sensing fire detector with point type temperature sensing element also includes a point type temperature sensing element 7 installed at the cable joint B and connected to the conversion box 2 through two conductors 8 , the conversion box 2 detects the temperature of the linear temperature sensing element 1 an...

Embodiment 3

[0026] In this embodiment, one of the two detection conductors on the linear temperature sensing element 1 in Embodiment 1 and Embodiment 2 is made of thermocouple wire material, and forms a temporary thermocouple with the other, thereby forming a thermocouple The characteristic linear temperature sensing element, while other structures and working principles are the same as the above two embodiments.

[0027] The point-type temperature sensing element 7 is one of a thermistor, a thermocouple or a thermosensitive switch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com