Method for preparing multi-element doping lithium iron phosphate by taking ferrous metallurgy sludge as main raw material

A technology of iron and steel metallurgy and lithium iron phosphate, which is applied in the field of preparing multi-component doped lithium iron phosphate, which can solve problems such as large differences in composition and characteristics, low value-added utilization, and vicious cycle enrichment of harmful elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

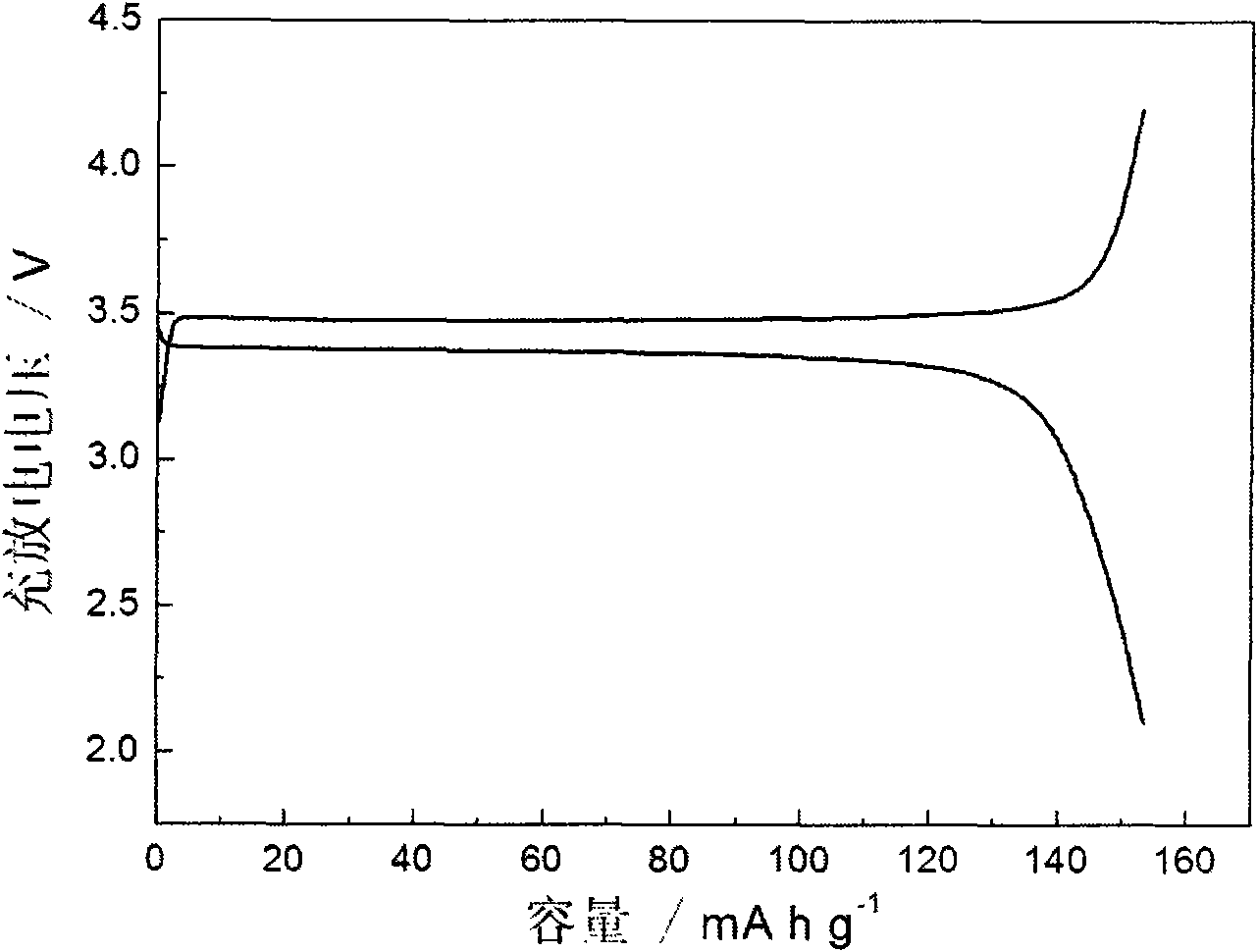

[0019] Embodiment: take by weighing 100g electric furnace dedusting ash and 20g coke (-80 order), pack graphite crucible, be placed in furnace at 1200 ℃ in N 2 Roast in atmosphere for 3 hours, take out and air cool to room temperature. The processed sample is subjected to grinding and magnetic separation to obtain an Fe-based multi-element alloy phase containing various doping elements. The obtained Fe-based multi-element alloy was oxidized at 500° C. for 3 hours in an air environment to obtain a composite oxide. Detect the composition of complex oxides, according to the chemical formula The stoichiometric ratios shown were dosed. Weigh 20g composite oxide, 14.98g NH 4 h 2 PO 4 , 5.58g LiOH 2H 2 0 and 3g of polypropylene powder were mixed and ball milled (rotating speed 400rpm, time 2 hours). The ground powder was placed in a ceramic crucible and heated at 700 °C under N 2 Roasting under protection for 6 hours, cooling to room temperature with the furnace, that is, mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com