Method for preparing multielement-doped lithium iron phosphate by using waste phosphate slag as main raw material

A technology of phosphating waste slag and lithium iron phosphate, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve problems such as methods for comprehensive utilization of phosphating waste slag that have not been found, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

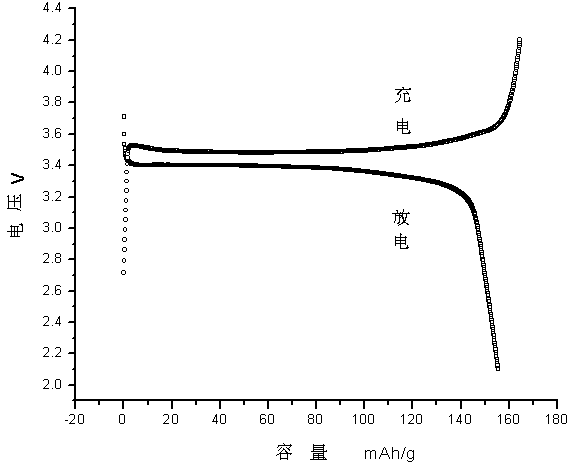

Image

Examples

Embodiment 1

[0024] Embodiment 1: take by weighing the phosphating waste residue of 250g water content 90% color partial green, drop 1ml H 2 o 2 , 1ml of 0.01mol / L dilute phosphoric acid, briefly stir until the color is uniform white or yellowish white. Add 50ml of 0.005mol / L dilute hydrochloric acid, adjust the pH value to 3~4 with ammonia water, heat and stir in a water bath at 60°C for 15min, take 5ml of filtrate after filtration, add excess NaOH solution dropwise, if there is no obvious red precipitate, repeat the above acid wash steps. The resulting filter residue was dried in an oven at 180°C for 2 hours. Its composition was measured by XRF, and the relative molar percentages of Fe, P and each doping element were: 48.57%, 50.12%, and 1.31%, respectively. Do thermogravimetric analysis, after drying at 180°C, every 10g of filter residue contains 0.62g of crystal water. Weigh 10g of filter residue and add 2.61g of LiOH.H 2 O, 1.5g polypropylene powder, ball milling (380rpm, 6h). A...

Embodiment 2

[0025] Example 2: Weigh 250g of white or yellow-white phosphating waste residue with a moisture content of 90%, add 50ml of 0.001mol / L dilute phosphoric acid, adjust the pH value to 3~4 with ammonia water, heat and stir in a water bath at 80°C for 10min, and filter Finally, take 5ml of filtrate and add excess NaOH solution dropwise. If there is no obvious red precipitate, repeat the above pickling step. The resulting filter residue was dried in an oven at 100°C for 4 hours. Its composition was measured by XRF, and the relative molar percentages of Fe, P and each doping element were: 47.53%, 50.35%, and 2.12%, respectively. According to thermogravimetric analysis, every 10g of filter residue contains 1.21g of crystal water after drying at 100°C. Weigh 10g of filter residue and add 2.44g of LiOH.H 2 O, 1.5g polypropylene powder, ball milling (450rpm, 4h). After ball milling, the sample was placed in an enamel crucible at 700 °C, N 2 Roasting under protection for 6 hours, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com