Method for preparing polynary doped lithium ferrous phosphate by using copper scale extract as main raw material

A technology of lithium iron phosphate and main raw materials, applied in the field of preparing multi-component doped lithium iron phosphate, can solve the problems of not many, unfavorable structure and composition of copper slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

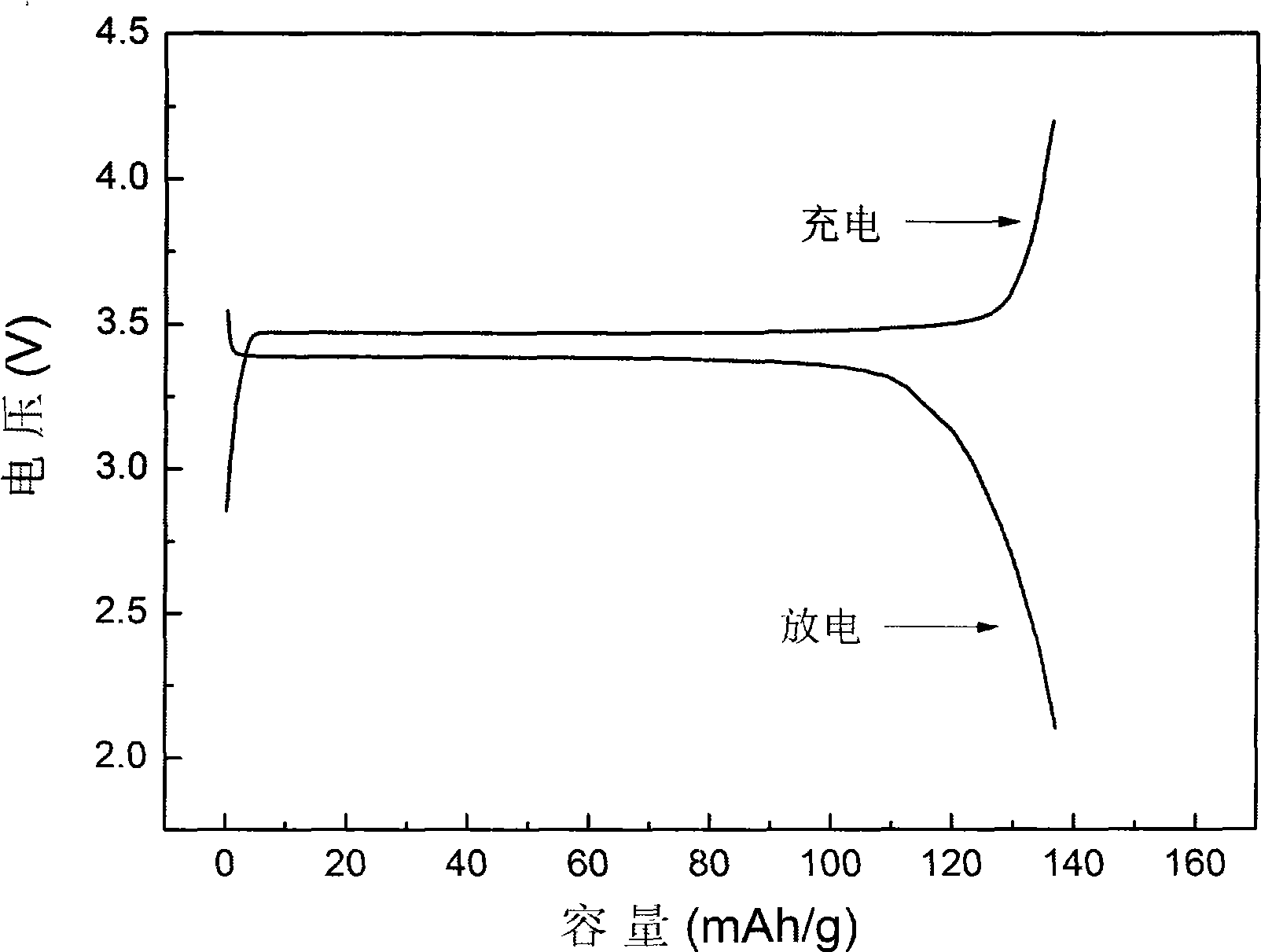

Embodiment 1

[0019] Embodiment 1: Take by weighing 100g converter copper slag grain (particle diameter 1mm~5mm) and 40g coke (-40 order), put into graphite crucible, be placed in the furnace at 1200 ℃ in N 2 Roast in atmosphere for 2 hours, take out and air cool to room temperature. The treated copper slag is ground and magnetically separated to obtain an Fe-based multi-element alloy phase containing various doping elements. XRF test shows that the total molar concentration of doping elements is 7.24%, and the rest is Fe. The obtained Fe-based multi-element alloy phase was oxidized at 500° C. for 3 hours in an air environment to obtain a composite oxide. Weigh 10g composite oxide, 13.9gNH 4 h 2 PO 4 , 5.35g LiOH·2H 2 0 and 3g polypropylene powder are batched, and the prepared material is ball milled at 400 rpm for 2 hours. The ground powder was placed in a ceramic crucible and heated at 700 °C under N 2 Roasting under protection for 6 hours, and cooling to room temperature with the f...

Embodiment 2

[0020] Example 2: Weigh 100g of converter copper slag particles (1mm to 8mm in particle size) and 100g of coke (-40 mesh), put them into a graphite crucible, put it in a furnace at 1100°C in an air atmosphere and cover it for roasting for 2 hours, take it out and cool it in air to room temperature. The treated copper slag is ground and magnetically separated to obtain an Fe-based multi-element alloy phase containing various doping elements. XRF test shows that the total molar concentration of doping elements is 6.58%, and the rest is Fe. The obtained Fe-based multi-element alloy phase was oxidized at 600° C. for 2 hours in an air environment to obtain a composite oxide. Weigh 10g composite oxide, 14.5gNH 4 h 2 PO 4 , 5.58g LiOH 2H 2 0 and 3g polypropylene powder are batched, and the prepared material is ball milled at 400 rpm for 2 hours. The ground powder was placed in a ceramic crucible and heated at 650 °C under N 2 Roasting under protection for 10 hours, cooling to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com