Motorcycle frame

A motorcycle and frame technology, which is applied in the field of cradle-type split frame, can solve the problems of increased packaging and transportation costs, troublesome loading and fastening of the engine, and high labor intensity of workers, so as to reduce the difficulty of disassembly and assembly and reduce the difficulty of workers labor intensity, reduce packaging and transportation costs, and reduce packaging and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

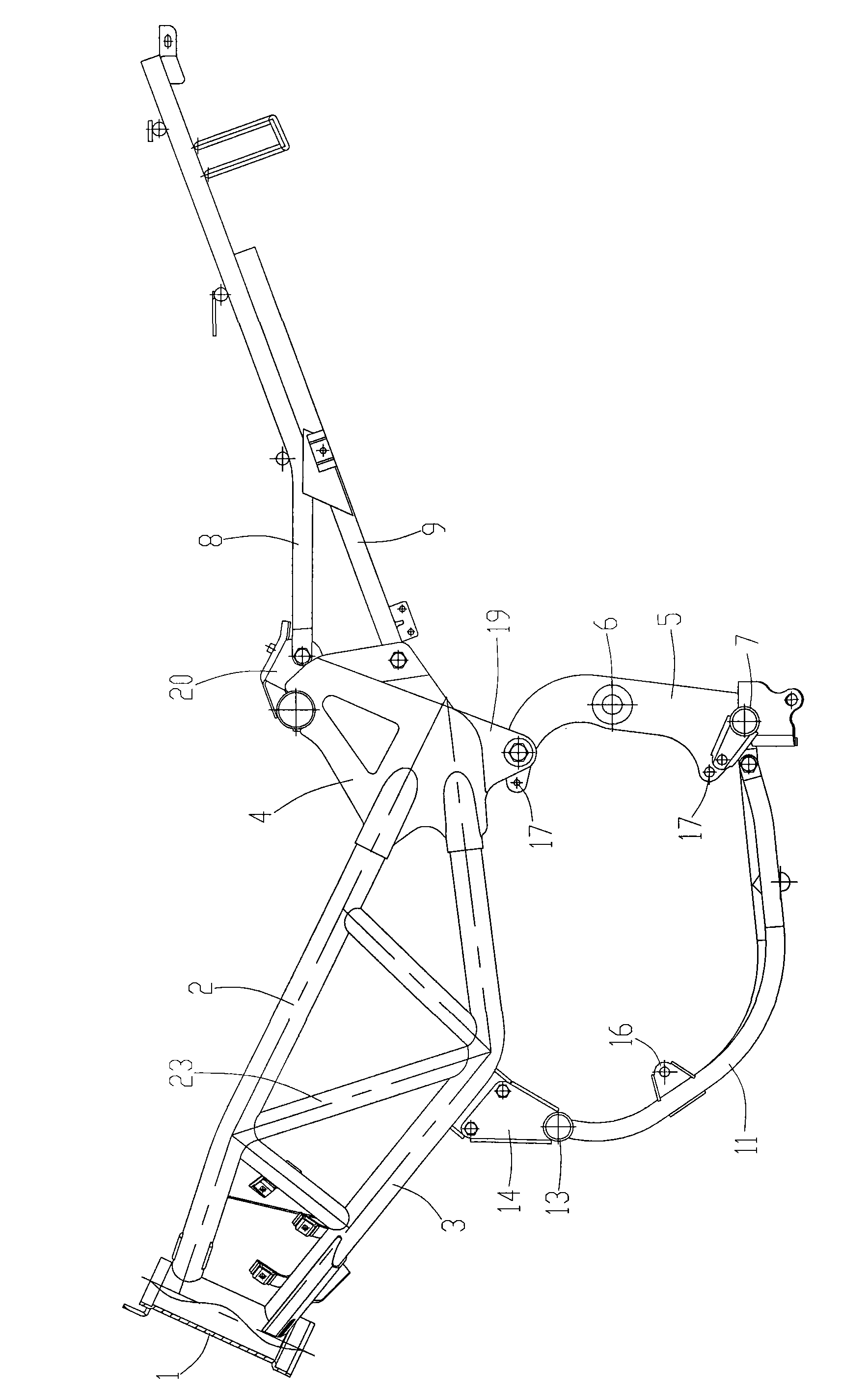

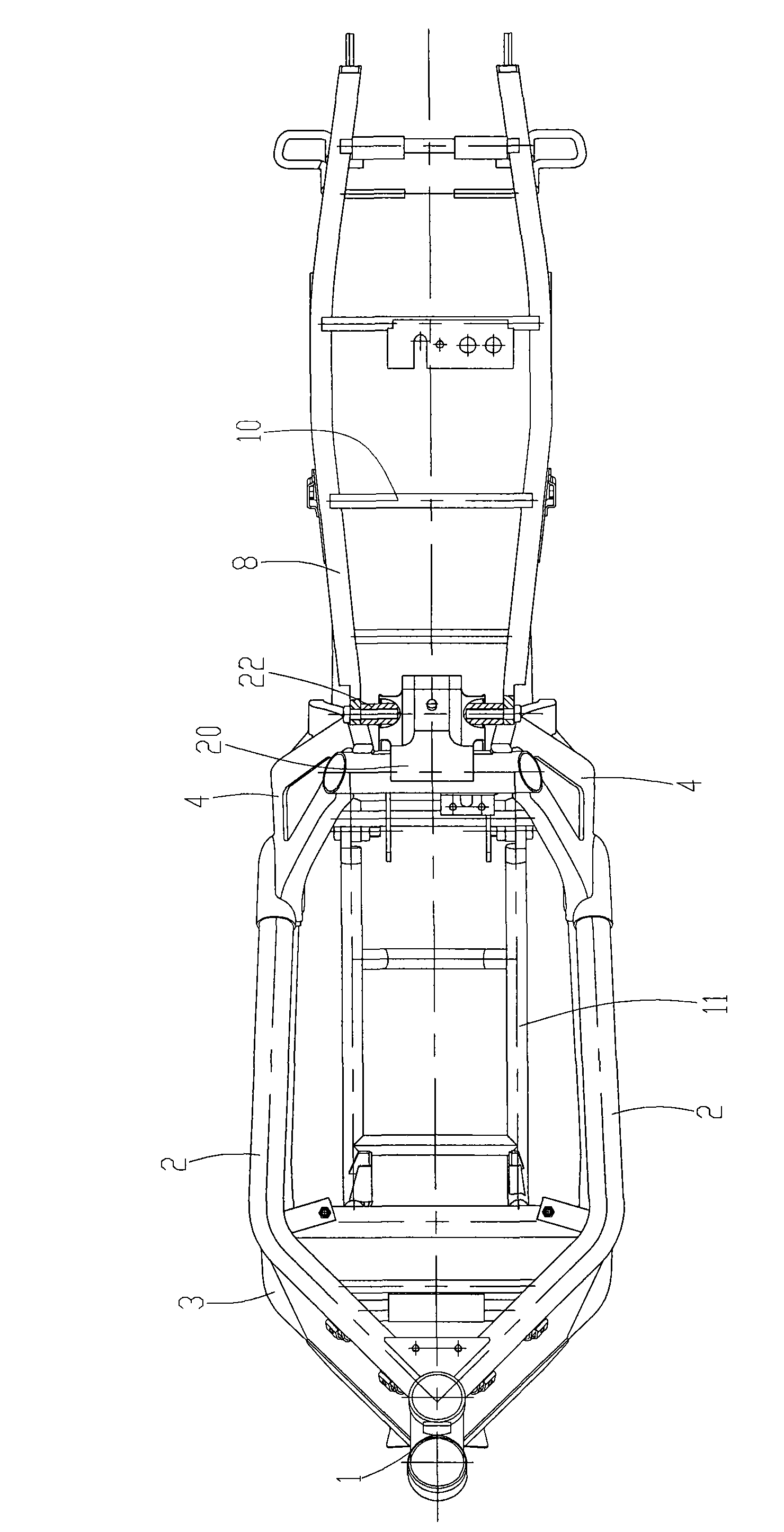

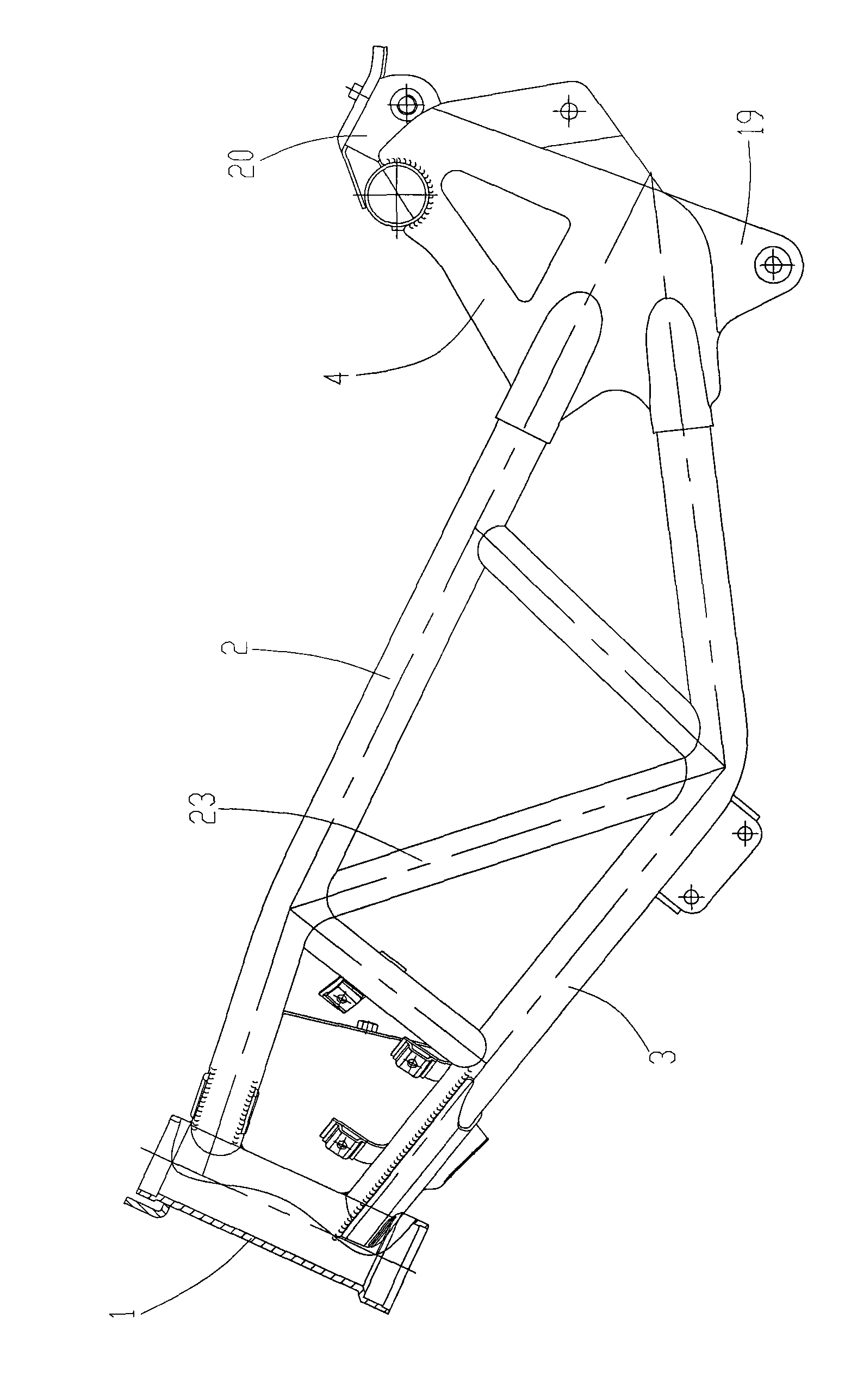

[0029] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, the present invention is made of four major parts such as front body combination, middle body combination, rear body combination and engine suspension combination. Among them, the front body combination includes the front riser 1, the upper connecting pipe 2, the lower connecting pipe 3, the connecting plate 4 and the rear mounting bracket 20 of the fuel tank. The lower connecting pipe 3 and the two connecting plates 4 are symmetrically arranged left and right. The front ends of the two upper connecting pipes 2 are folded inward and welded to the upper end of the front riser 1. Welded with the connecting plate 4 on the corresponding side, the tops of the left and right two connecting plates 4 are jointly welded to support the rear mounting bracket 20 of the fuel tank, and a hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com