Visual experimental equipment and visual experimental method for researching dispersing action mechanism of grinding sheet

A technology of dispersion and experimental equipment, applied in the field of papermaking, to achieve the effect of improving accuracy, accurate picture data, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

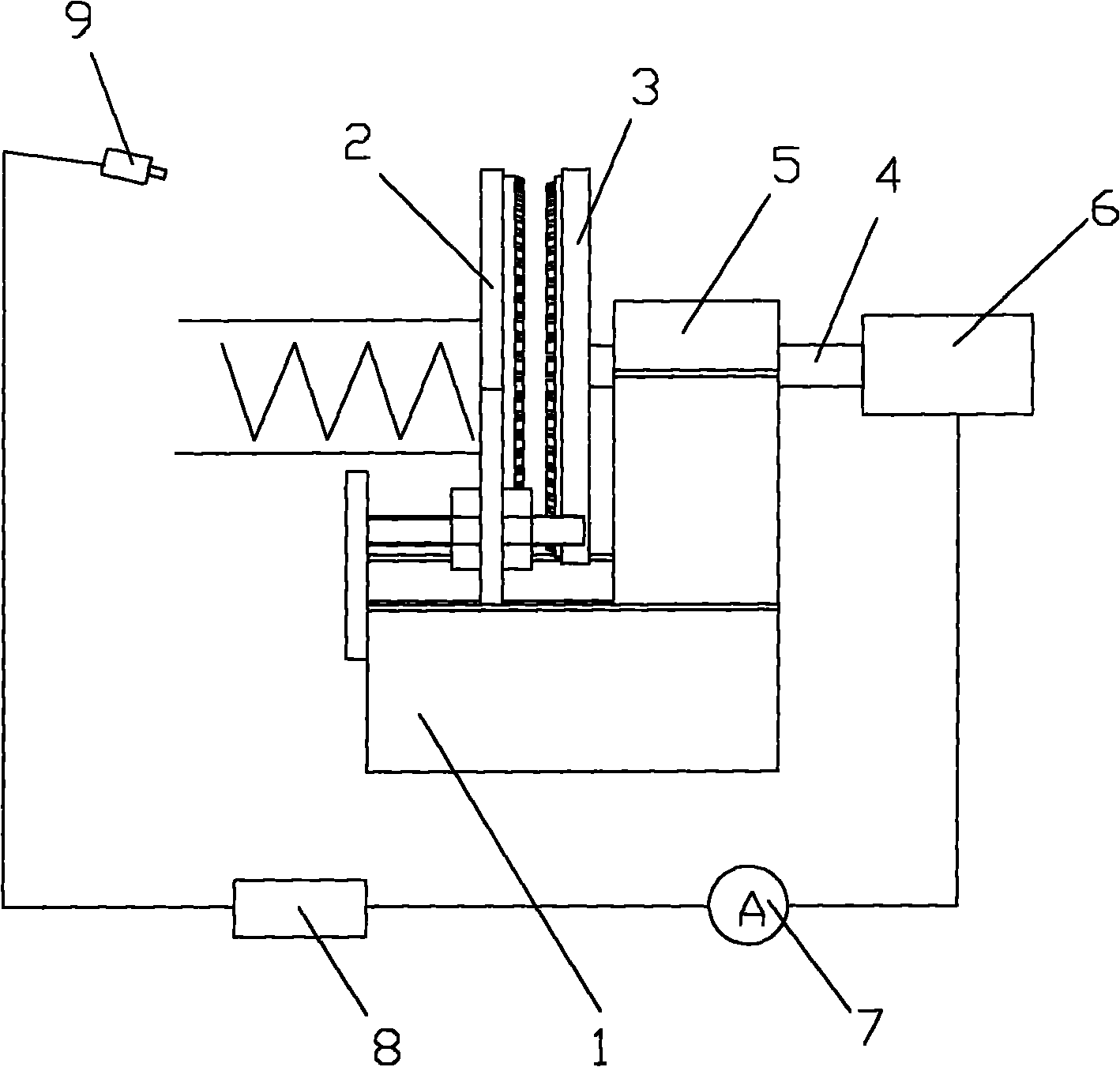

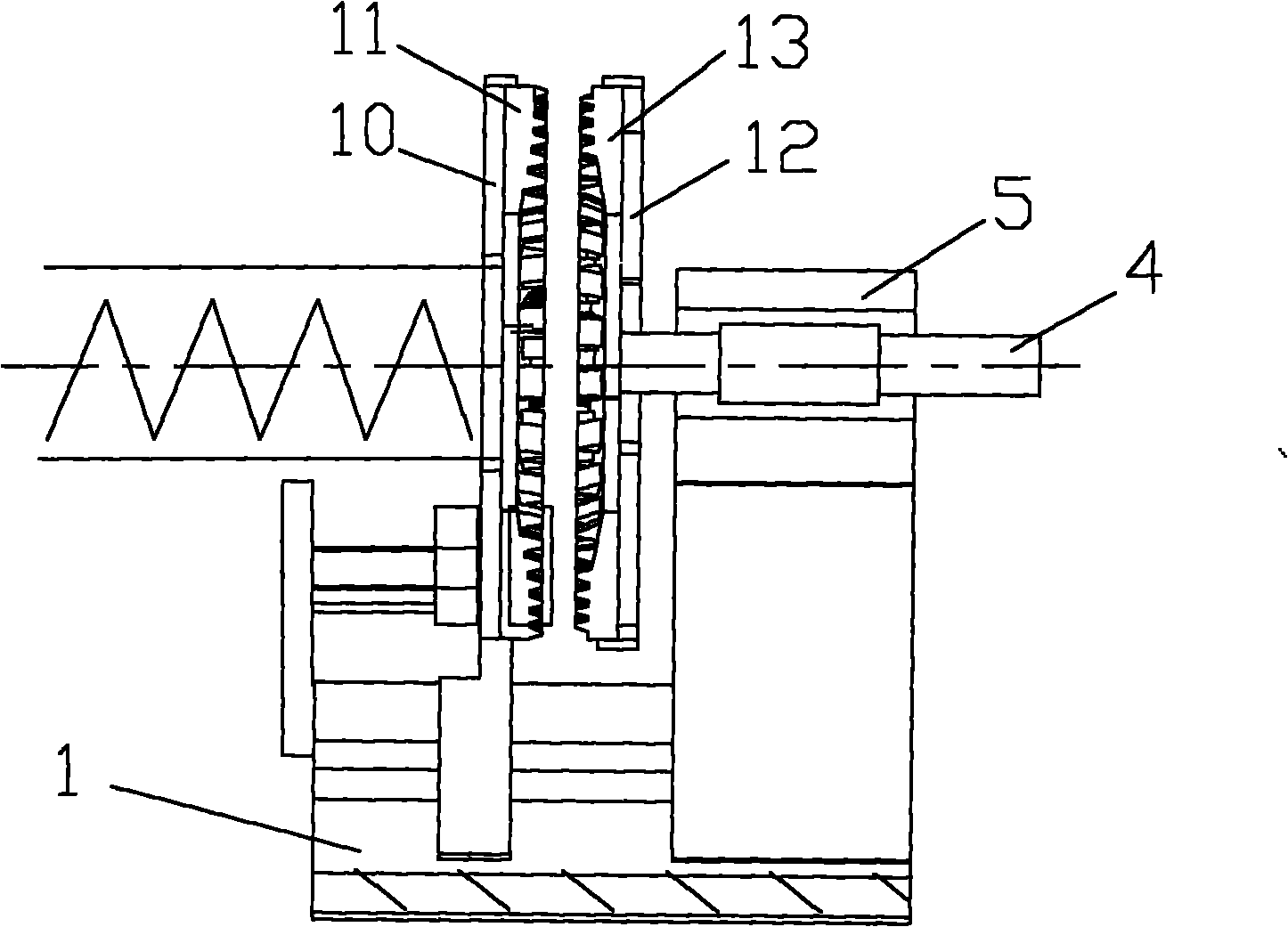

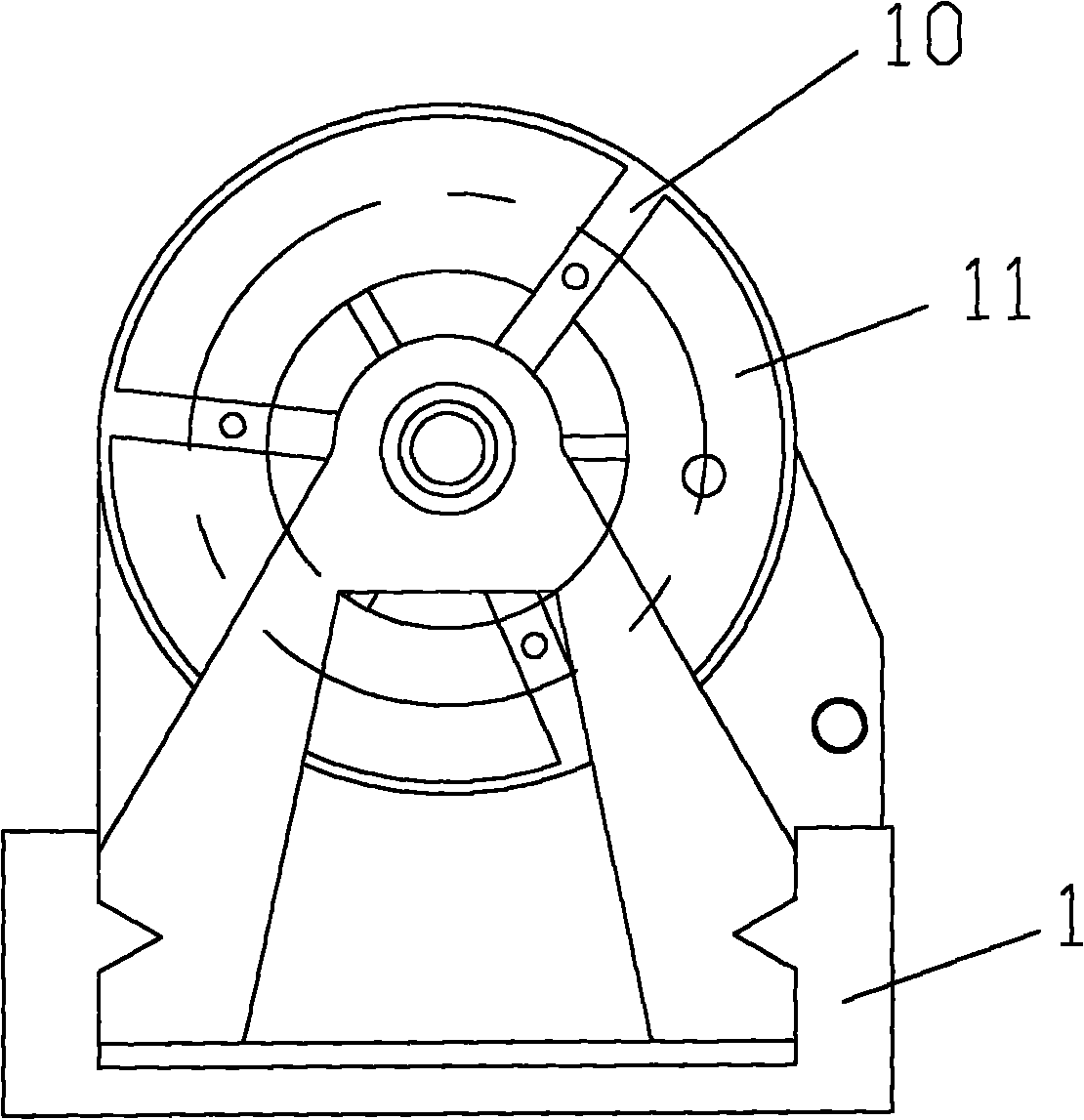

[0030] This embodiment is a kind of visual experimental equipment used for the research on the mechanism of the dispersion effect of the grinding plate. Its structure is as follows figure 1 As shown, it includes a disc grinding mechanism and a data acquisition mechanism. The disc grinding mechanism includes a base 1, a static plate assembly 2 and a moving plate assembly 3. The static plate assembly 2 and the moving plate assembly 3 are respectively arranged on the base 1, and are simultaneously connected through the main shaft 4. Shaft setting, the end of the main shaft on one side of the moving film assembly 3 is connected to the motor 6 through a coupling; the data acquisition mechanism includes a current detection device 7 connected to the motor 6 in sequence, a speed control device 8 and a camera 9, and the camera 9 is located at Above the disc grinding mechanism, the data acquisition mechanism is externally connected to the experimental data processing system.

[0031] li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com