Numerical control bender control system

A control system and bending machine technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as large errors, insufficient control accuracy, and inaccurate position calculation, and achieve high accuracy , The processing process is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

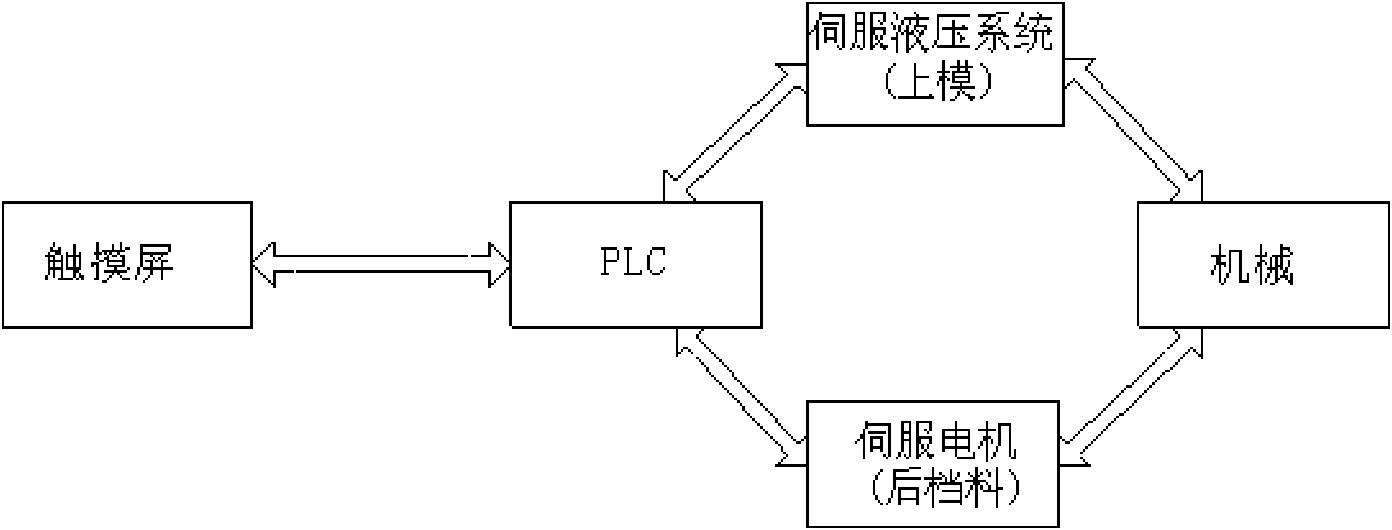

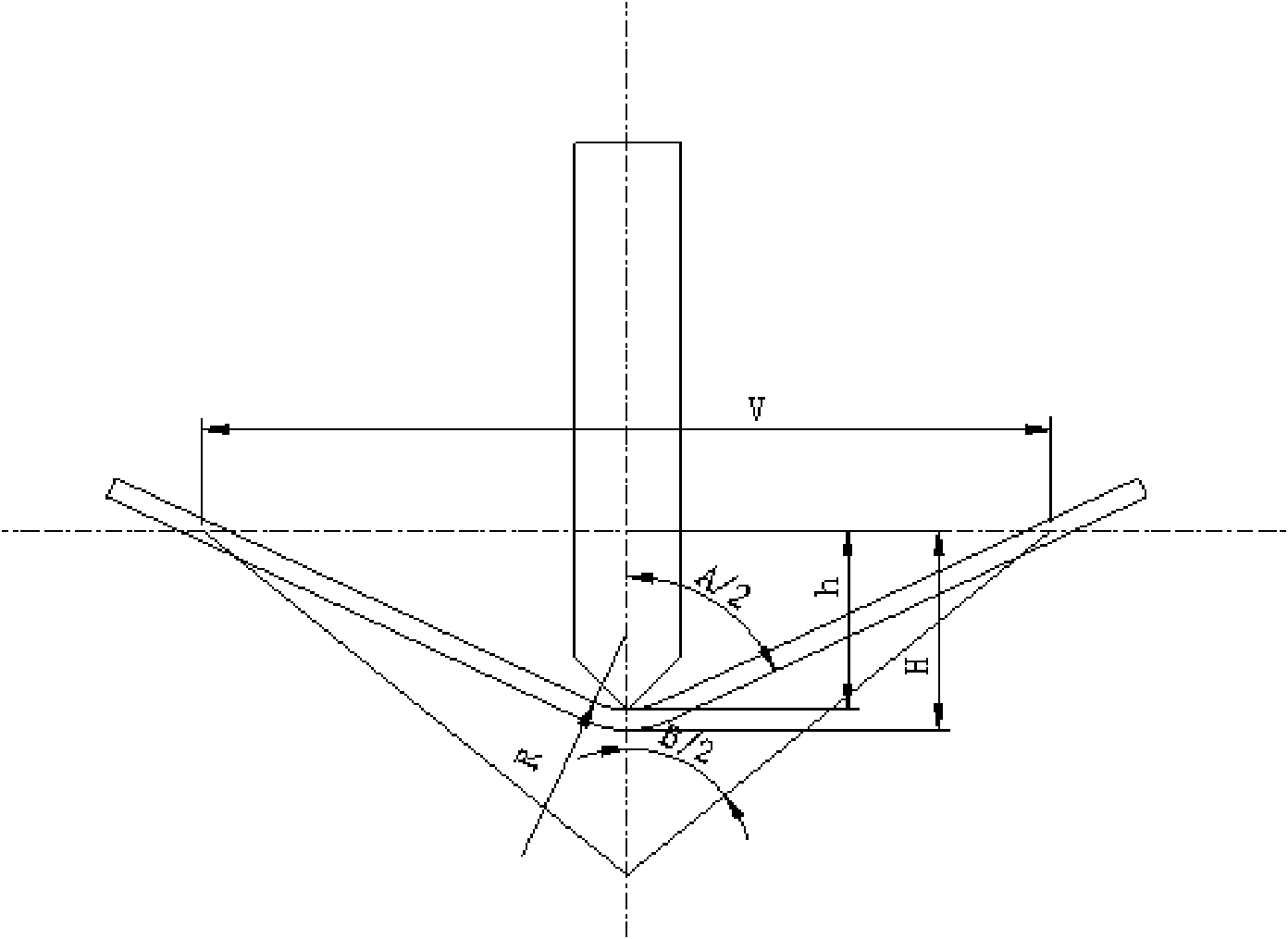

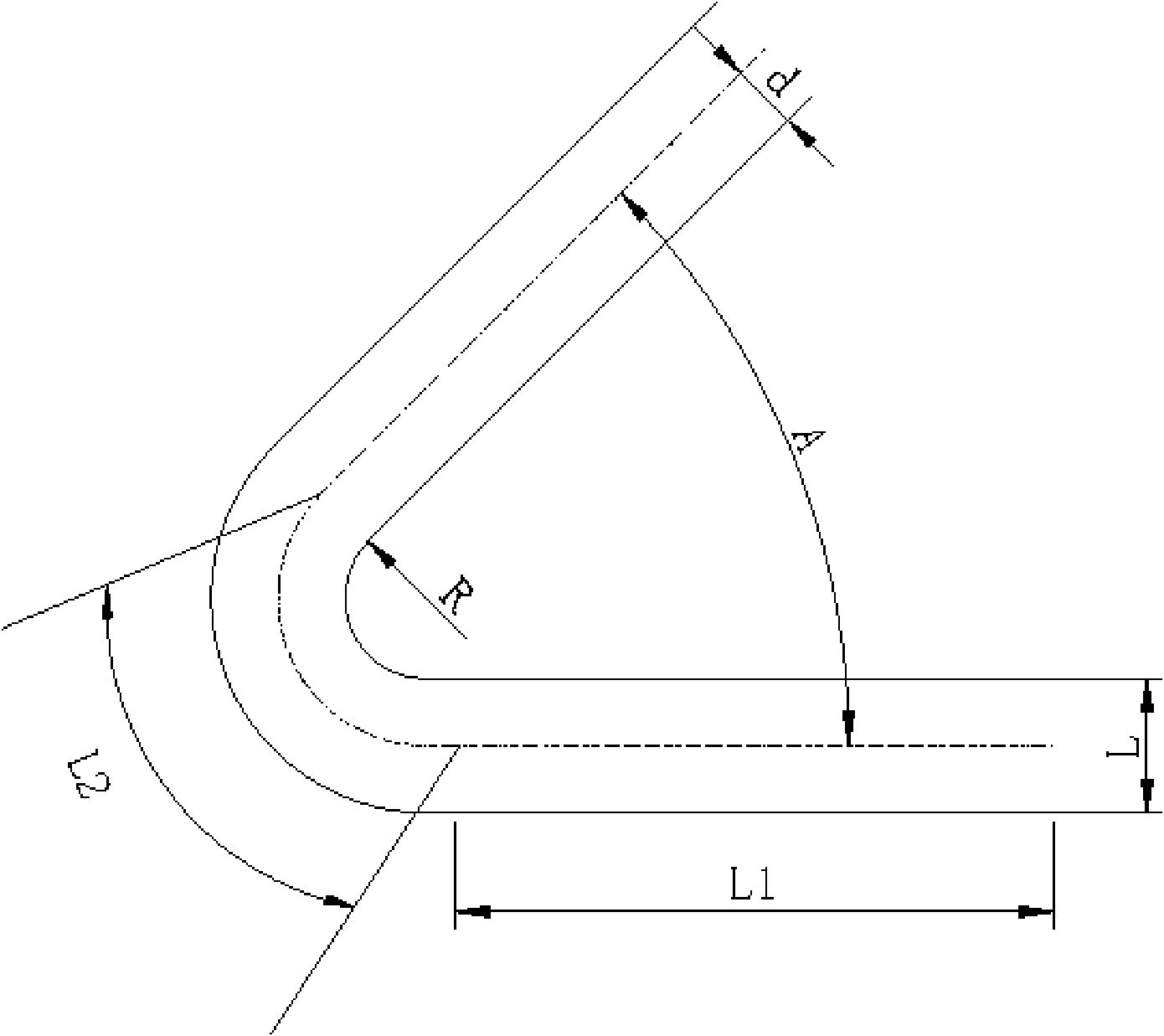

[0029] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention includes bending mechanical parts, servo hydraulic feeding system, servo motor, and it also includes a touch screen, PLC programmable logic controller, the touch screen collects the bending related parameter information input by the user, and calculates the effective value that can be directly used by the PLC. Data, the parameters related to the calculation in the collected data include: target angle, upper die angle, lower die opening, lower die angle, back gauge position, material thickness, material width, use these parameters to calculate and convert the pressure, depth, The corrected back gauge position is sent to the PLC to control the operation of the bending mechanical parts; according to the collected data information, the relationship curve about the bending radius is fitted through the BP neural network, and the intermediate variable of the bending radius is used to calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com