Ferromagnetic oxide powder for magnetic recording and preparation method thereof

A technology for ferrite magnetism and magnetic recording, which is applied to the preparation of ferrite magnetic powder for magnetic recording, and the field of ferrite magnetic powder for magnetic recording, which can solve the problem of unfavorable magnetic card hysteresis loop rectangularity and difficulty in preparing ferrite. Insufficient reaction of bulk magnetic powder and ferrite to achieve the effect of fine particle size, narrow particle size distribution and lower pre-sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 500g of iron red with a purity of 98.5%, 111g of barium carbonate with a purity of 98.8%, and 1.8g of Bi 2 o 3 , 0.5g nano-SiO 2 and 0.5g nano-Al 2 o 3 , using a vibration mill to mix to obtain a mixture;

[0037] After the mixture is pelletized with water, it is pre-sintered at 1050°C for 2 hours in an electric furnace;

[0038] After cooling, use a dry ball mill for coarse crushing to an average particle size of 2.8 μm, then use a ball mill for wet fine grinding for 1-4 hours to an average particle size of 0.96 μm, dry and anneal at 850°C for 30 minutes, and finally use a high-speed Disperse with a pulverizer to obtain ferrite magnetic powder.

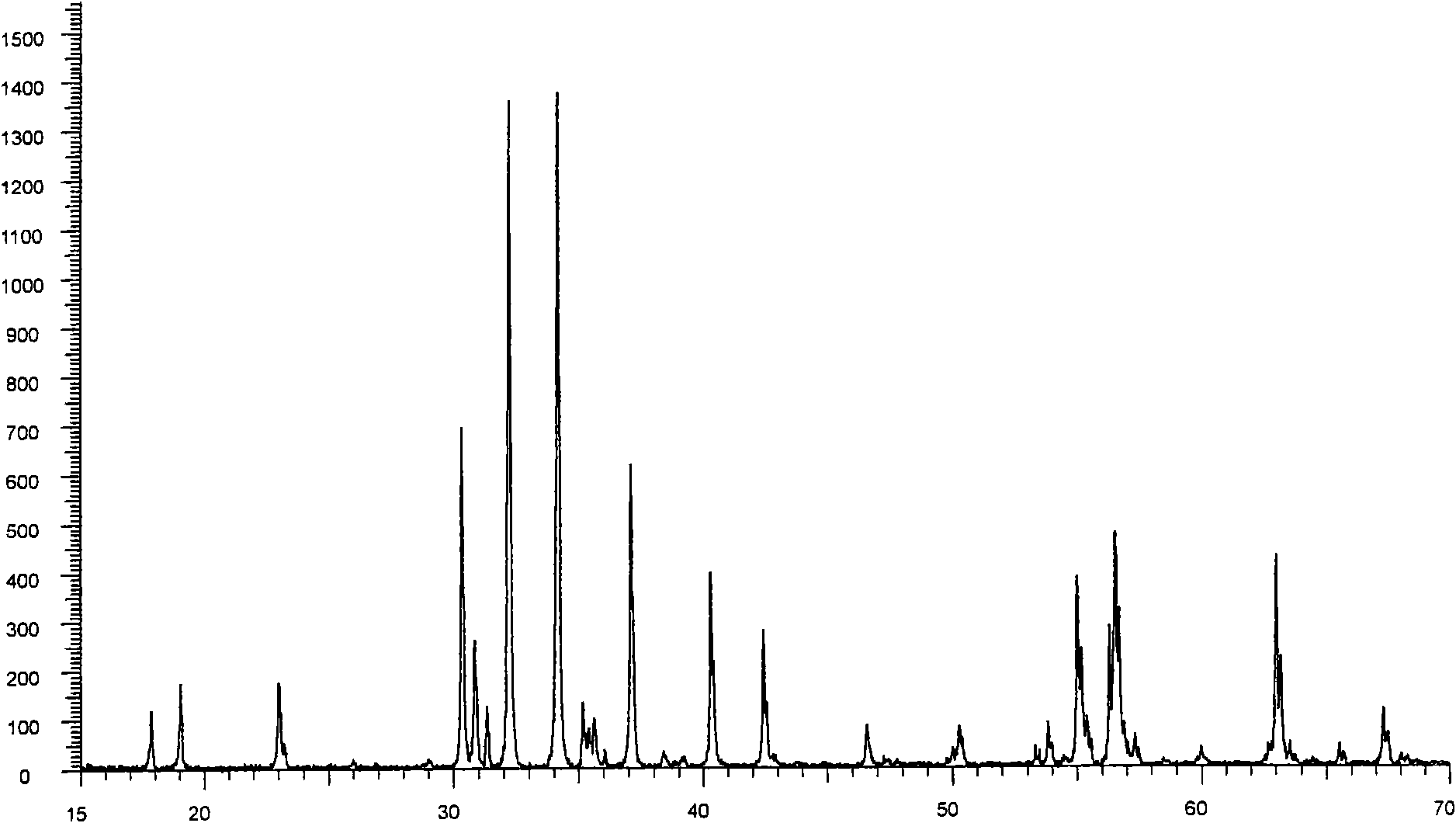

[0039] The average particle size of the magnetic powder is detected by the WLP-202 model average particle size tester; the particle size distribution test is carried out by the HELOS / RODOS model laser particle size distribution tester; the magnetic performance test is carried out by the VSM method. figure 1 The XRD patte...

Embodiment 2

[0041] 500g of iron red with a purity of 98.5%, 83g of strontium carbonate with a purity of 99%, and 1.7g of Bi 2 o 3, 0.5g nano-SiO 2 and 0.5g nano-Al 2 o 3 , using a vibration mill to mix to obtain a mixture;

[0042] After the mixture is pelletized with water, it is pre-sintered at 1080°C for 2 hours in an electric furnace;

[0043] After cooling, use a dry ball mill for coarse crushing to an average particle size of 2.8 μm, then use a ball mill for wet fine grinding for 1-4 hours to an average particle size of 0.97 μm, dry and anneal at 850°C for 30 minutes, and finally use a high-speed Disperse with a pulverizer to obtain ferrite magnetic powder.

[0044] The average particle size of the magnetic powder is detected by the WLP-202 model average particle size tester; the particle size distribution test is carried out by the HELOS / RODOS model laser particle size distribution tester; the magnetic performance test is carried out by the VSM method.

Embodiment 3

[0046] 500g of iron red with a purity of 98.5%, 132g of barium carbonate with a purity of 98.5%, and 1.8g of Bi 2 o 3 , 0.5g nano-SiO 2 and 0.5g nano-Al 2 o 3 , using a vibration mill to mix to obtain a mixture;

[0047] After the mixture is pelletized with water, it is pre-sintered at 1070°C for 2 hours in an electric furnace;

[0048] After cooling, use a dry ball mill for coarse crushing to an average particle size of 2.6 μm, then use a ball mill for wet fine grinding for 1-4 hours to an average particle size of 0.95 μm, dry and anneal at 850°C for 30 minutes, and finally use a high-speed Disperse with a pulverizer to obtain ferrite magnetic powder.

[0049] The average particle size of the magnetic powder is detected by the WLP-202 model average particle size tester; the particle size distribution test is carried out by the HELOS / RODOS model laser particle size distribution tester; the magnetic performance test is carried out by the VSM method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com