Bonding welding disk lowering parasitic capacitance and preparing method thereof

A technology for bonding pads and pads, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as pad metal layer peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

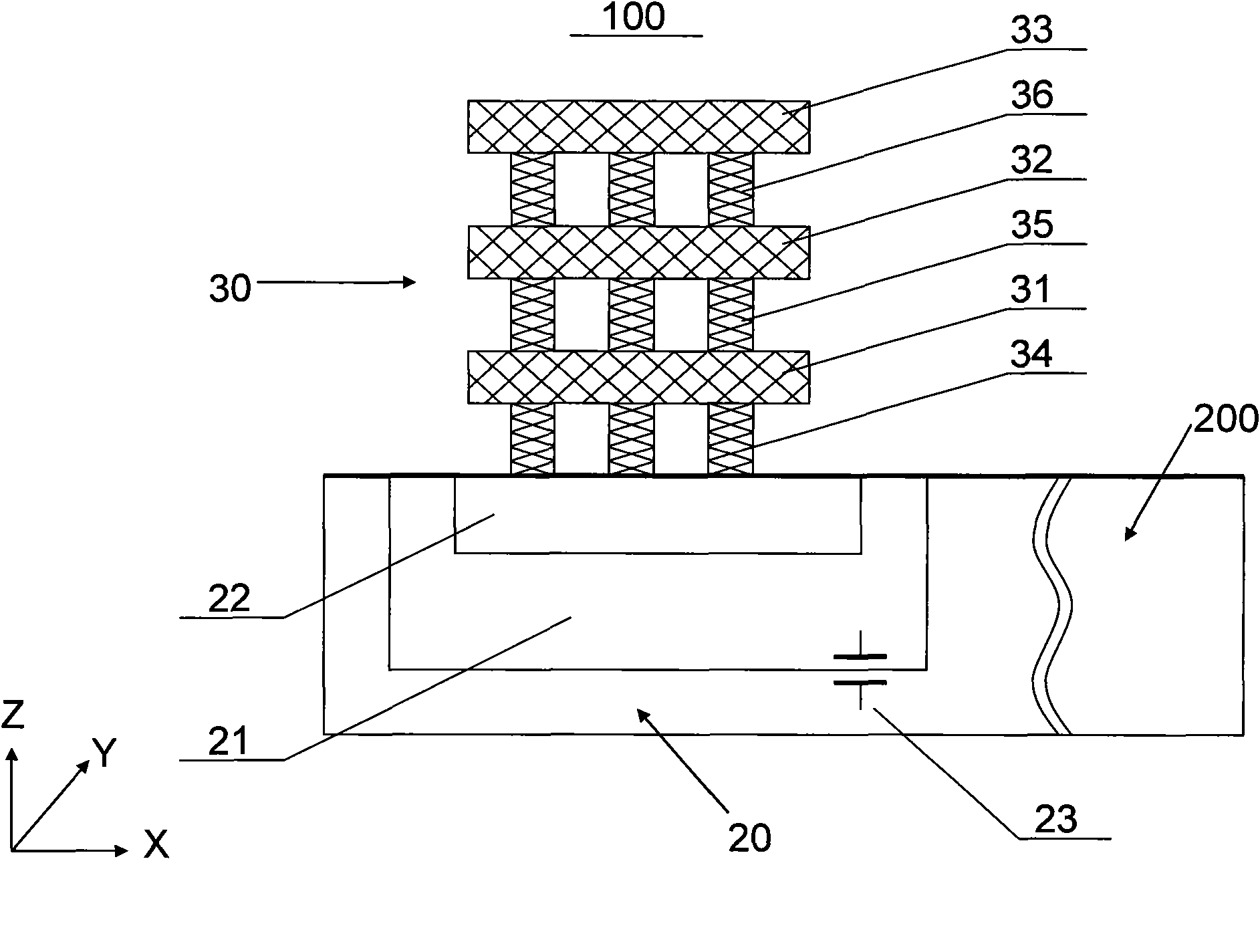

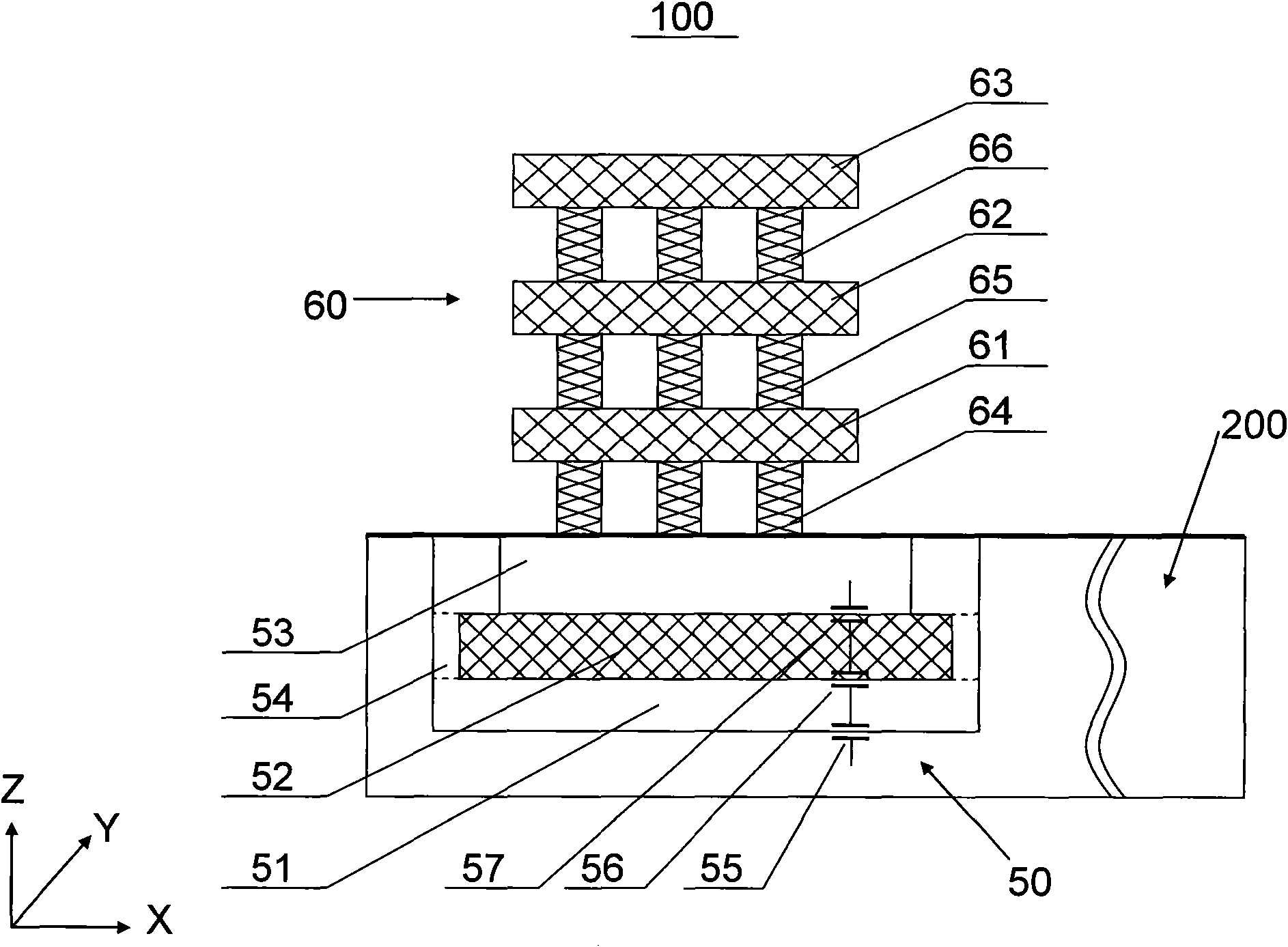

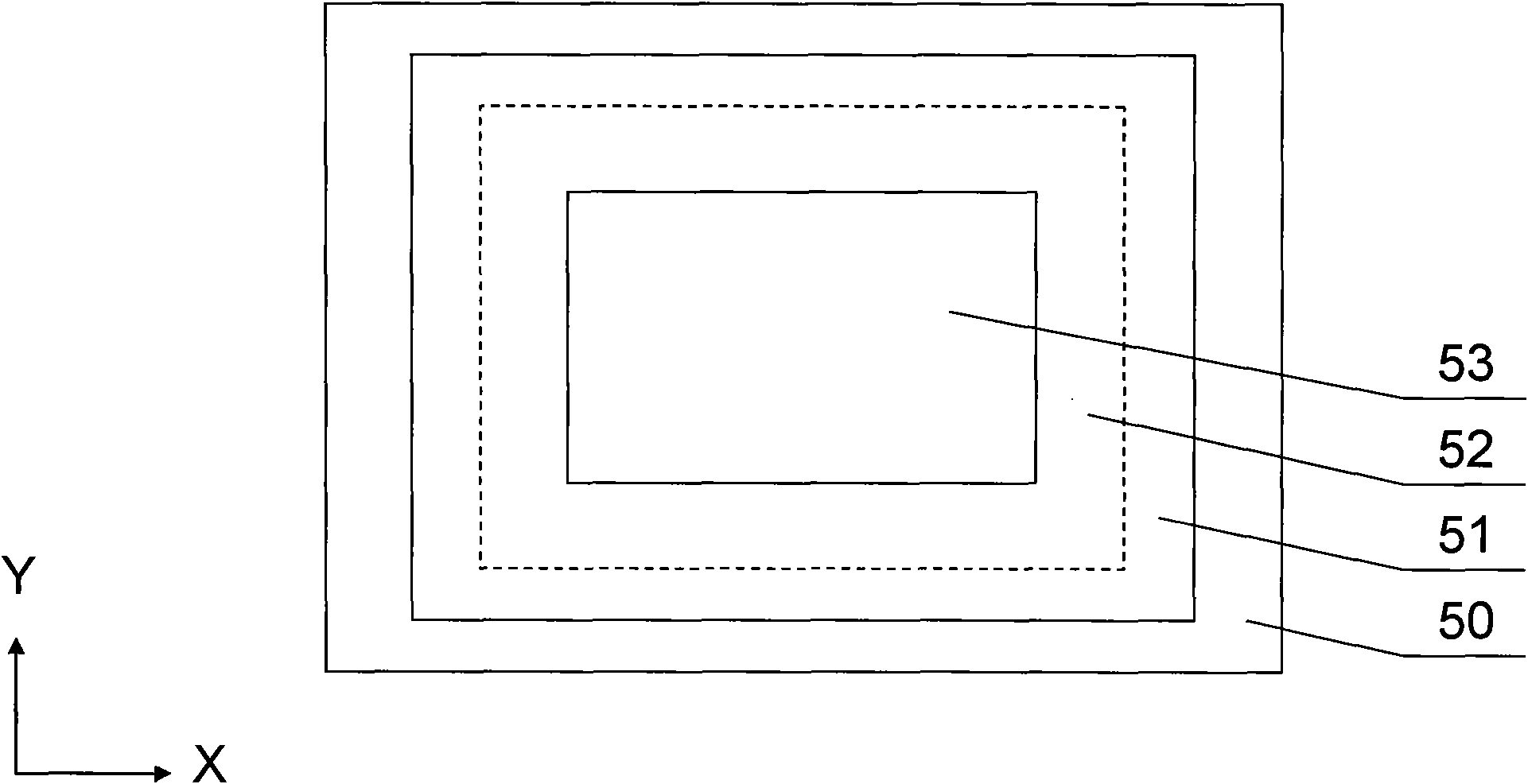

[0044] figure 2 Shown is a schematic diagram of the structure of the bonding pad provided by the present invention. The direction perpendicular to the surface layer on the semiconductor substrate is defined as the Z direction, and the plane parallel to the surface layer on the semiconductor substrate is defined as the XY plane. The bonding pad includes the semiconductor substrate 50 and the pad metal layer 60. The semiconductor substrate includes a semiconductor substrate (not shown in the figure) in the active device area and a semiconductor substrate 50 in the bonding pad area. The upper surface layer of the semiconductor substrate 50 is doped with semiconductors to form a first semiconductor Doped well region 51, in the first semiconductor doped well region 51...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com