Motor control system

A technology for a control device and a motor, which is applied in the directions of motor control, electric controller, program control, etc., can solve the problems of increasing the burden of the computing device and the large amount of calculation, and achieve the effect of realizing model tracking control and reducing the burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

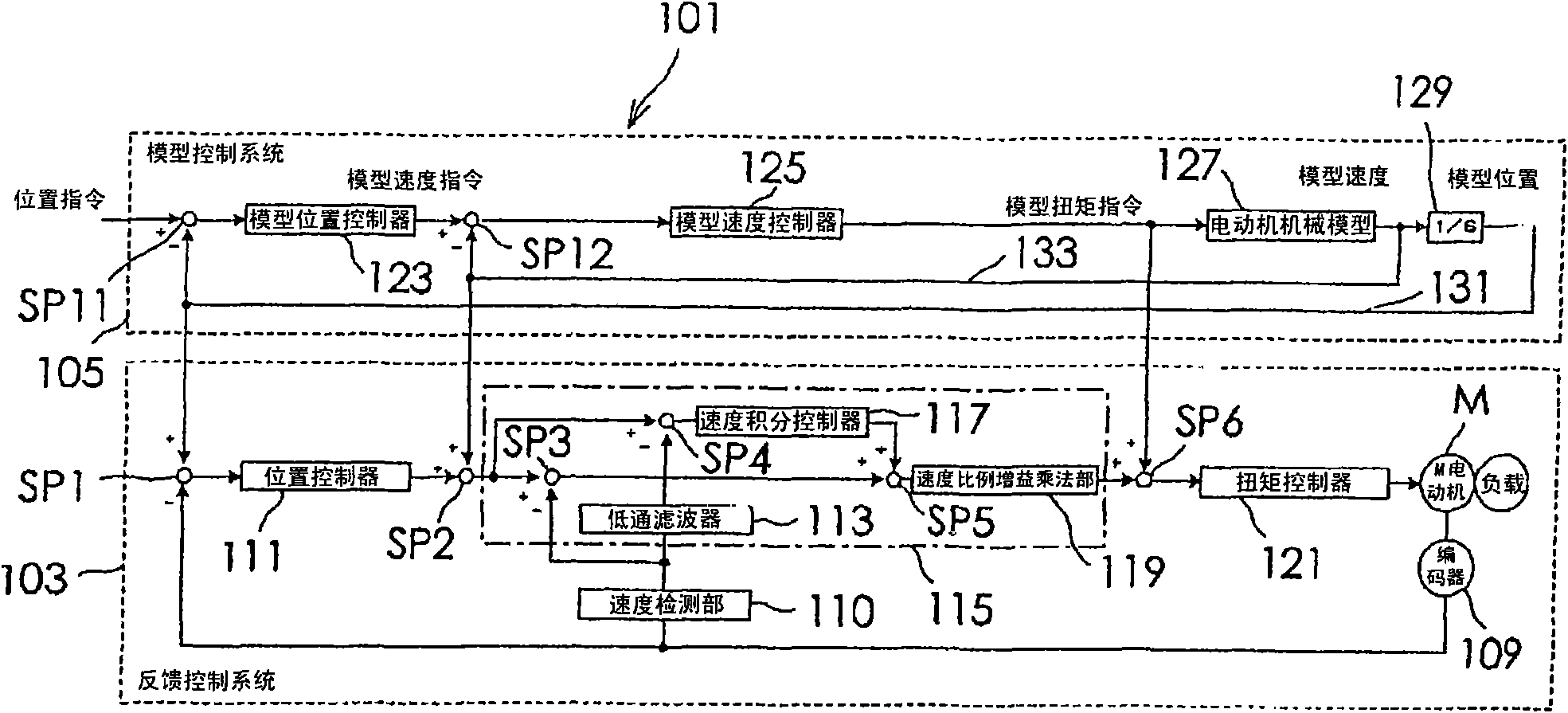

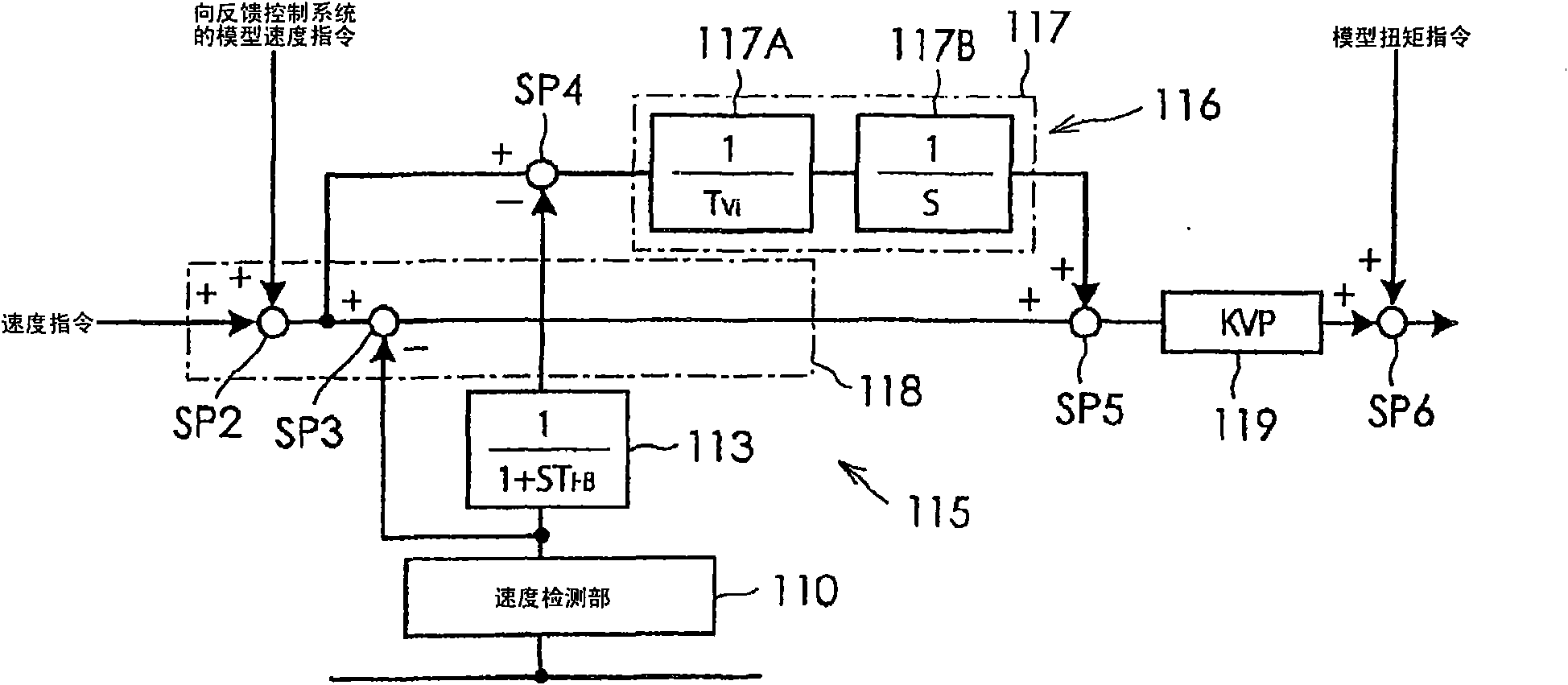

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a block diagram showing the configuration of the motor control device of the present invention. figure 2 It is a schematic diagram showing the specific configuration of main parts of the feedback control system 103 . The motor control device 101 of this embodiment is composed of a feedback control system 103 and a model control system 105 . The feedback control system 103 includes: a position sensor 109 composed of an encoder that detects the rotational position of the motor M; a position controller 111 ; a speed detector 110 ; a speed controller 115 ; and a torque controller 121 . The output (position information) of the position sensor 109 is fed back to the position controller 111, and the output (position information) of the position sensor 109 is differentiated by the speed detection unit 110 to be filtered by the low-pass filter 113 as sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com