Steel bridge deck pavement structure and pavement method thereof

A bridge deck pavement and steel bridge deck technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of lack of innovative structures and complete sets of technologies, and achieve the effects of low engineering cost, increased waterproof effect, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

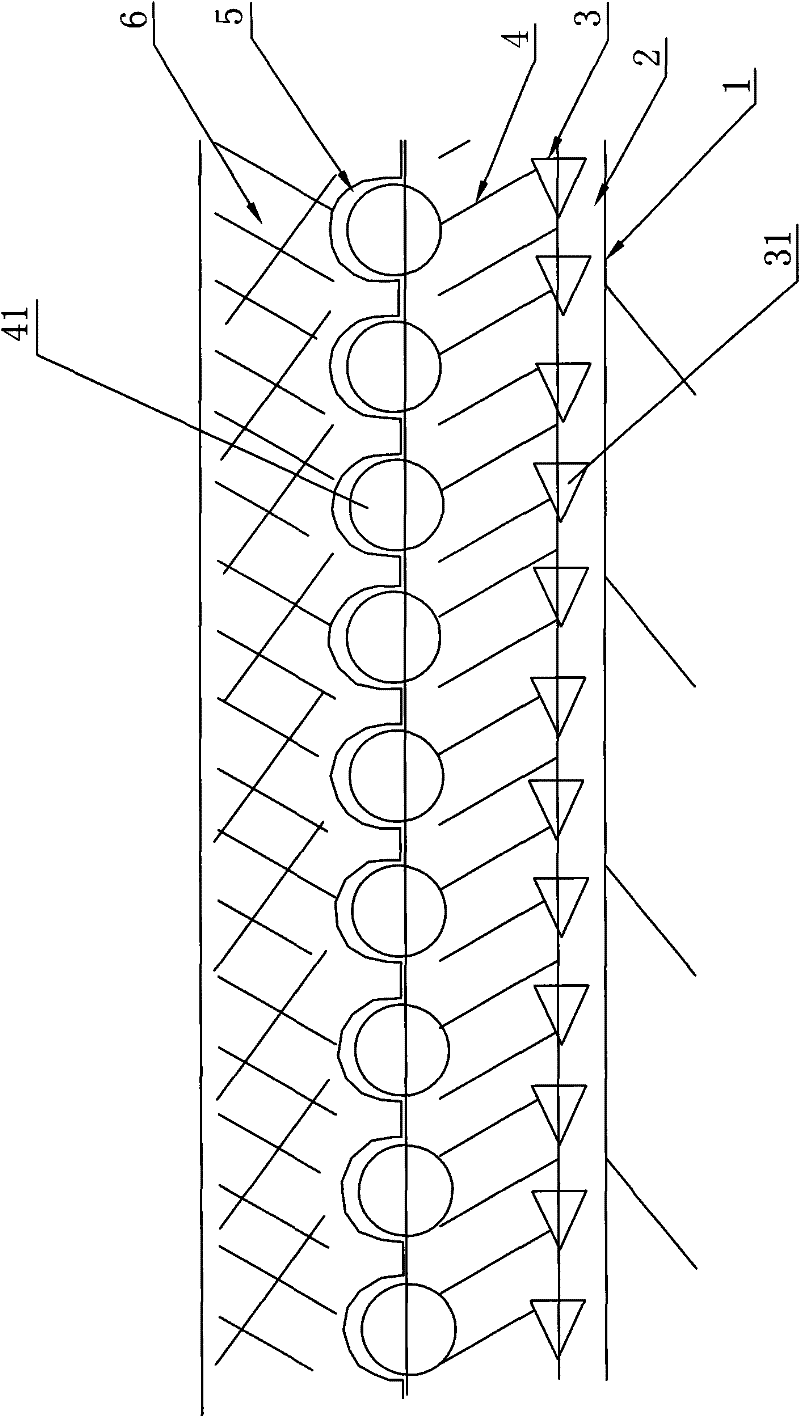

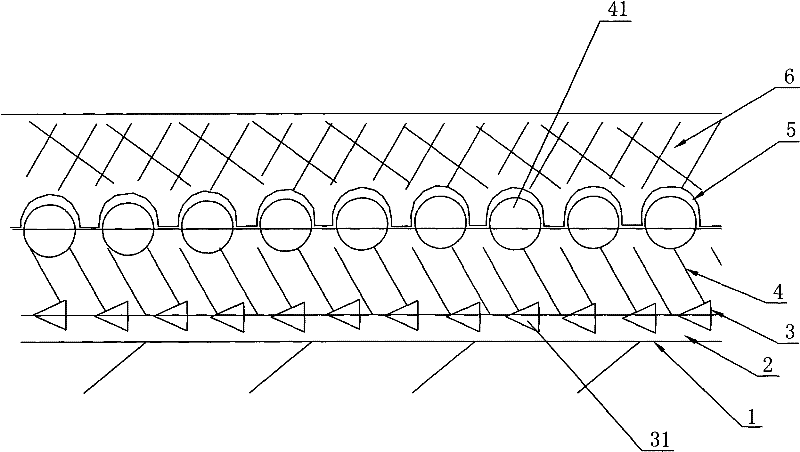

[0011] Embodiment 1: ① Sandblast and derust the bridge deck steel plate 1 to make it reach Sa2.5 level, and the roughness reaches 80 μm; 2 The standard scraping epoxy resin sizing material constitutes the epoxy bonding layer 2 immediately; 3. after the epoxy bonding layer 2 is scraping, sprinkle the small crushed stones 31 with a particle diameter of 4mm immediately, so that the small crushed stones 31 are bonded on the An epoxy bonded gravel layer 3 is formed on the epoxy bonded layer 2, and the ratio of the area occupied by the small gravel 31 to the area of the epoxy bonded layer 2 is 80%; A cold-mix resin asphalt concrete layer 4 with a thickness of 2.5 cm is laid above the layer 3, so that small crushed stones 31 are embedded in the cold-mix resin asphalt concrete layer 4. 12mm single-grain gravel 41 with an area ratio of 5% is spread on the upper surface of the upper surface, and the single-grain gravel 41 is partially embedded in the cold-mix resin asphalt concrete la...

Embodiment 2

[0012] Embodiment 2: 1. Sandblast and derust the bridge deck steel plate 1 to make it reach Sa2 level, and the roughness reaches 60 μm; 2 The standard scraping epoxy resin sizing material constitutes the epoxy bonding layer 2 immediately; 3. after the epoxy bonding layer 2 is scraping, sprinkle the small crushed stones 31 with a particle diameter of 3mm immediately, so that the small crushed stones 31 are bonded on the An epoxy bonded gravel layer 3 is formed on the epoxy bonded layer 2, and the ratio of the area occupied by the small gravel 31 to the area of the epoxy bonded layer 2 is 75%; A cold-mix resin asphalt concrete layer 4 with a thickness of 2.0 cm is laid above the layer 3, so that small crushed stones 31 are embedded in the cold-mix resin asphalt concrete layer 4. 12mm single-grain gravel 41 with an area ratio of 5% is spread on the upper surface of the upper surface, and the single-grain gravel 41 is partially embedded in the cold-mix resin asphalt concrete lay...

Embodiment 3

[0013] Embodiment 3: ① Sandblast and derust the bridge deck steel plate 1 to make it reach Sa3 level, and the roughness reaches 100 μm; 2 Scrape the epoxy resin sizing material to form the epoxy bonding layer 2 immediately; 3. sprinkle the small crushed stones 31 with a particle diameter of 5mm immediately after the epoxy bonding layer 2 is scraped, so that the small crushed stones 31 are bonded on the An epoxy bonded gravel layer 3 is formed on the epoxy bonded layer 2, and the ratio of the area occupied by the small gravel 31 to the area of the epoxy bonded layer 2 is 85%; A cold-mix resin asphalt concrete layer 4 with a thickness of 1.5 cm is laid above the layer 3, so that small crushed stones 31 are embedded in the cold-mix resin asphalt concrete layer 4. 12mm single-grain gravel 41 with an area ratio of 5% is spread on the upper surface of the upper surface, and the single-grain gravel 41 is partially embedded in the cold-mix resin asphalt concrete layer 4 through a ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com