Method for eliminating carbon deposited in exhaust pipe of diesel engine

A diesel engine and exhaust pipe technology, which is applied in the electronic control, exhaust treatment, and exhaust devices of exhaust gas treatment devices, can solve problems affecting the smooth exhaust gas performance of diesel engines, carbon deposition, and inability to increase engine operating temperature. and other problems, to achieve the effect of excellent exhaust maintenance and work performance and effective carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

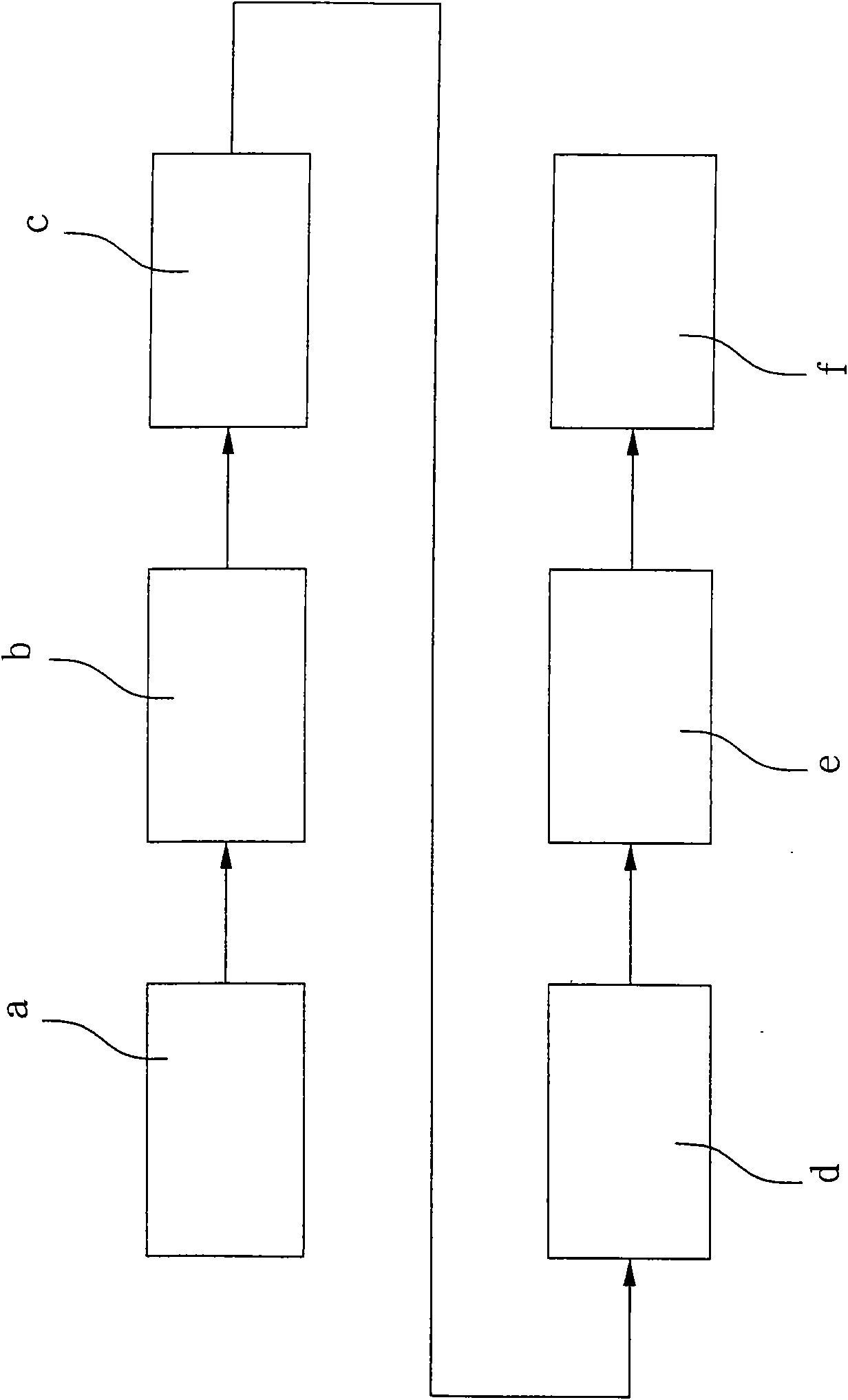

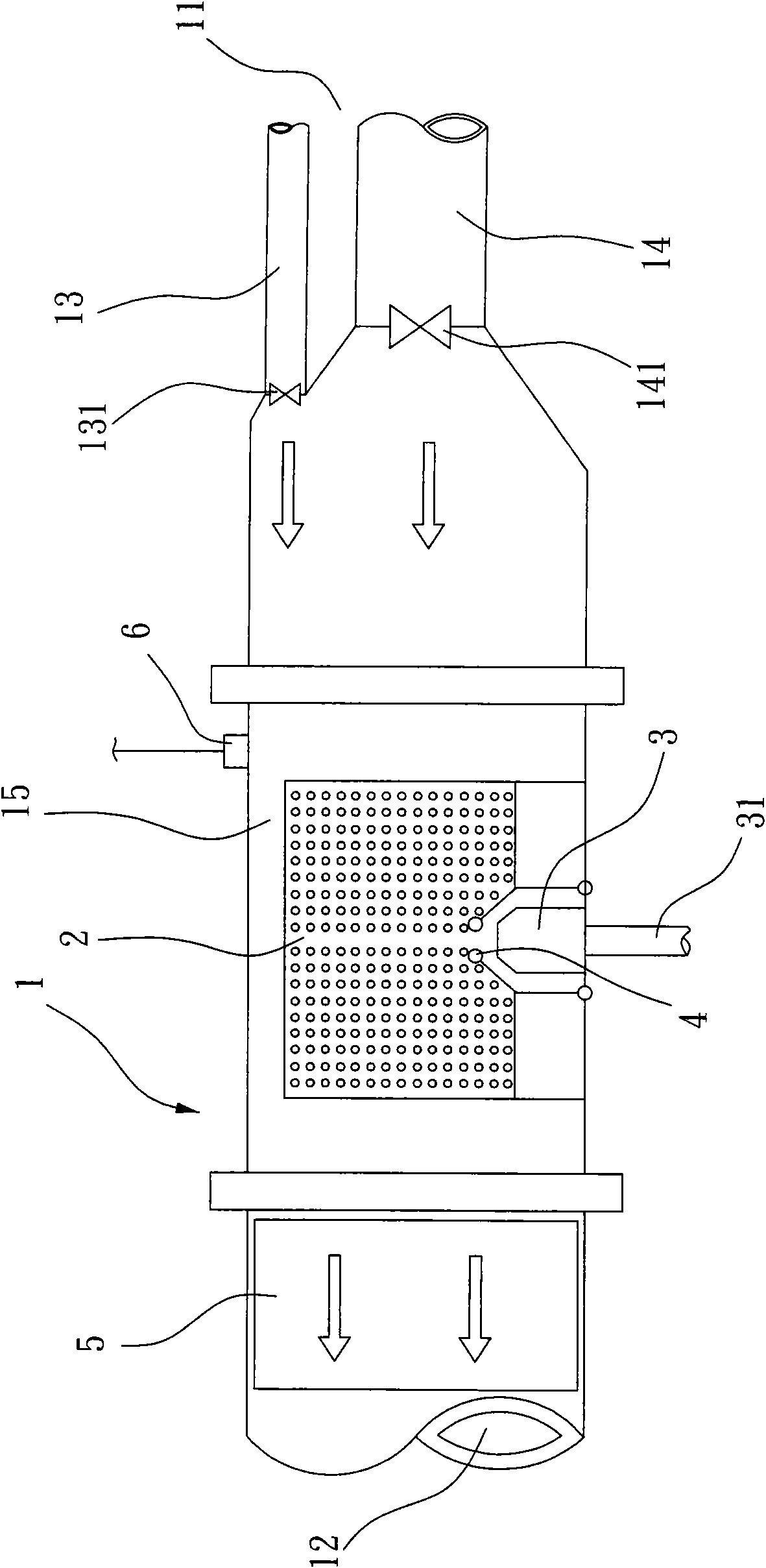

[0039] Such as figure 1 As shown, the method for eliminating carbon deposits in diesel engine exhaust pipes provided by the invention comprises the following steps:

[0040] a. Provide an exhaust pipe, the interior of which is provided with exhaust gas inlet and air inlet, combustion chamber and smoke exhaust purifier in sequence from the direction of air intake to outlet;

[0041] b. detecting the exhaust gas pressure before the exhaust purifier with a sensor;

[0042] c. When the exhaust gas pressure is higher than a preset value, the control system automatically opens the air inlet to guide fresh air into the exhaust pipe and pass through the combustion chamber;

[0043] d. Start a flame spraying device, atomize and inject fuel into the combustion chamber, mix and atomize with air, and ignite and burn to heat to 350°C-600°C;

[0044] e. Let the gas heated to 350°C to 600°C pass through the smoke exhaust purifier to ignite and remove carbon deposits;

[0045] f. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com