Residual sample gas cleaning device of electrochemical gas sensor and gas detecting device using same

A gas sensor and removal device technology, applied in the direction of material electrochemical variables, measuring devices, scientific instruments, etc., can solve problems affecting measurement accuracy, etc., and achieve the effect of simple structure and compact appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

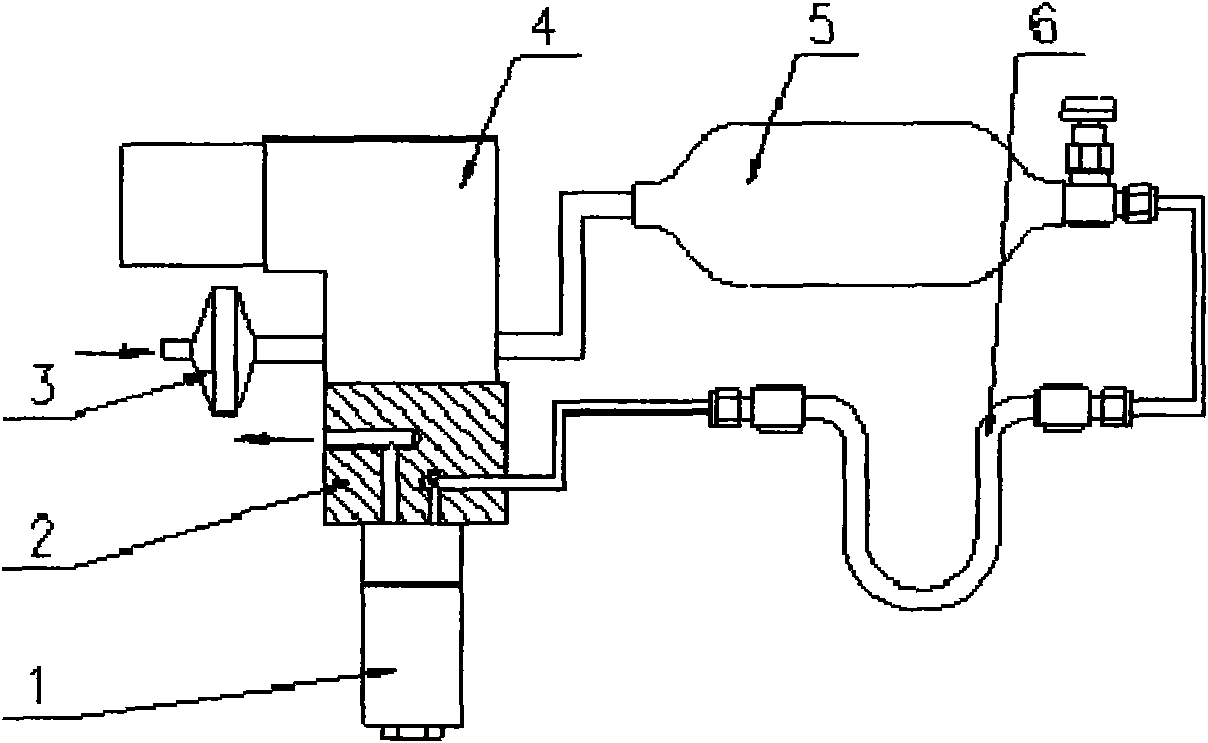

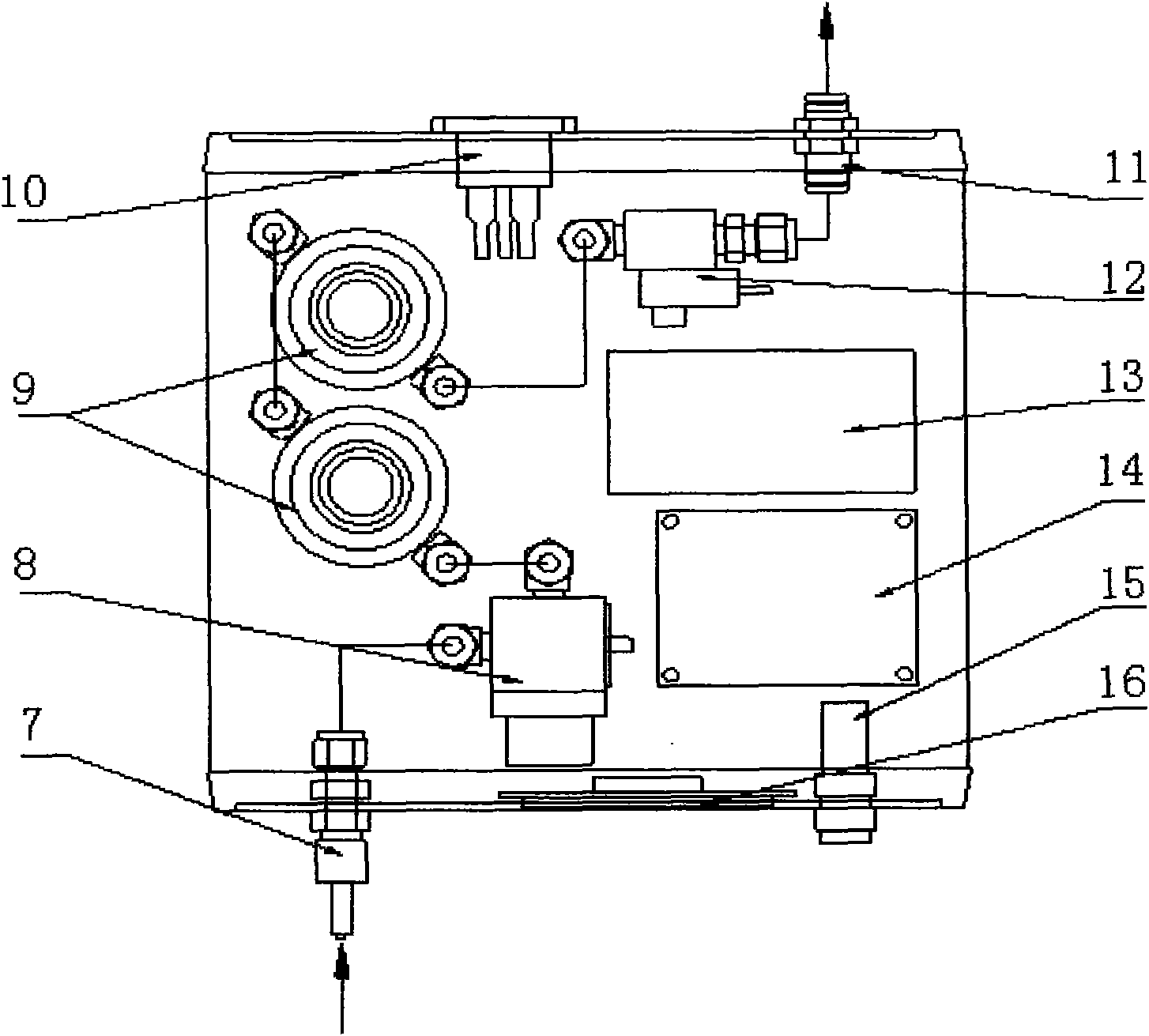

Embodiment 1

[0028] A residual sample gas removal device for an electrochemical gas sensor, consisting of a filter 3, a miniature vacuum pump 4, a buffer gas chamber 5, a gas circuit base 2 and a solenoid valve 1, the miniature vacuum pump 4 and the solenoid valve 1 are installed on the gas On the subgrade body 2. The solenoid valve is a normally closed solenoid valve. After each measurement of the electrochemical gas sensor, the solenoid valve is opened, the micro vacuum pump operates, the air enters the micro vacuum pump 4 through the filter 3, and the air pumped out by the micro vacuum pump 4 enters the buffer air chamber 5. The outlet end of the buffer air chamber 5 is provided with a pressure reducing valve, and the air in the buffer air chamber forms compressed air with a certain pressure. The air flowing out from the buffer gas chamber 5 enters the sample gas path of the electrochemical gas sensor through the solenoid valve 1 to form a pressure difference between the inside of the g...

Embodiment 2

[0033] A residual sample gas removal device for an electrochemical gas sensor, consisting of a filter 3, a micro vacuum pump 4, a buffer gas chamber 5, a gas circuit base 2, a polymer membrane air dryer 6 and a solenoid valve 1, the micro vacuum pump 4 And the solenoid valve 1 is installed on the air circuit substrate 2 . The solenoid valve is a normally closed solenoid valve. After each measurement of the electrochemical gas sensor, the solenoid valve is opened, the micro vacuum pump operates, the air enters the micro vacuum pump 4 through the filter 3, and the air pumped out by the micro vacuum pump 4 enters the buffer air chamber 5. The outlet end of the buffer air chamber 5 is provided with a pressure reducing valve, and the air in the buffer air chamber forms compressed air with a certain pressure. The air flowing out from the buffer air chamber 5 passes through the polymer membrane air dryer 6, and then enters the sample gas path of the electrochemical gas sensor through...

Embodiment 3

[0035] It is basically the same as Embodiment 1, except that the air path base body and the buffer air chamber form a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com