Excimer lamp

A technology of excimer lamps and discharge vessels, which is applied in the field of excimer lamps, can solve problems such as damage to the discharge vessel 61, achieve the effects of preventing damage to the discharge vessel, reducing damage such as ultraviolet strain, and reducing ultraviolet strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

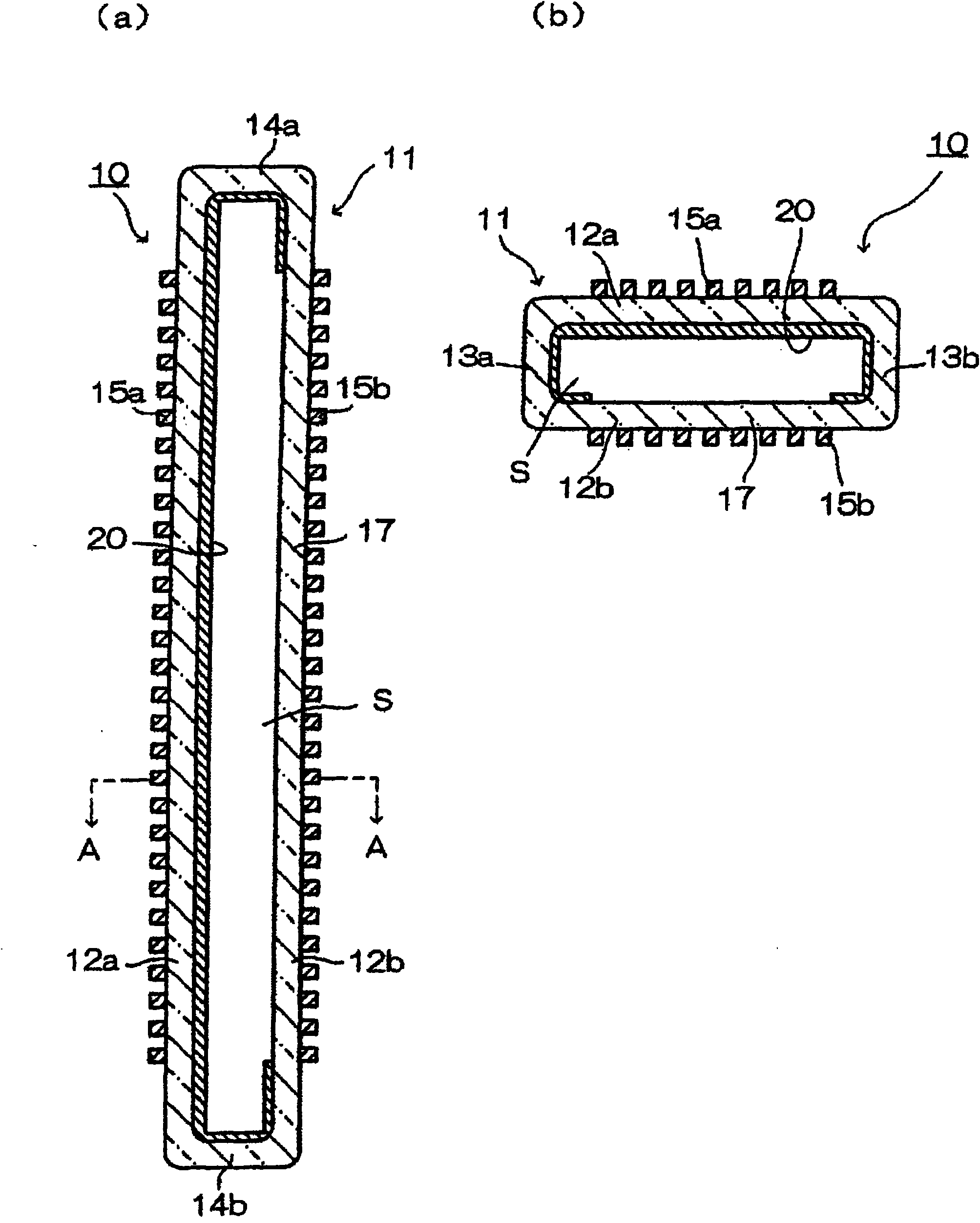

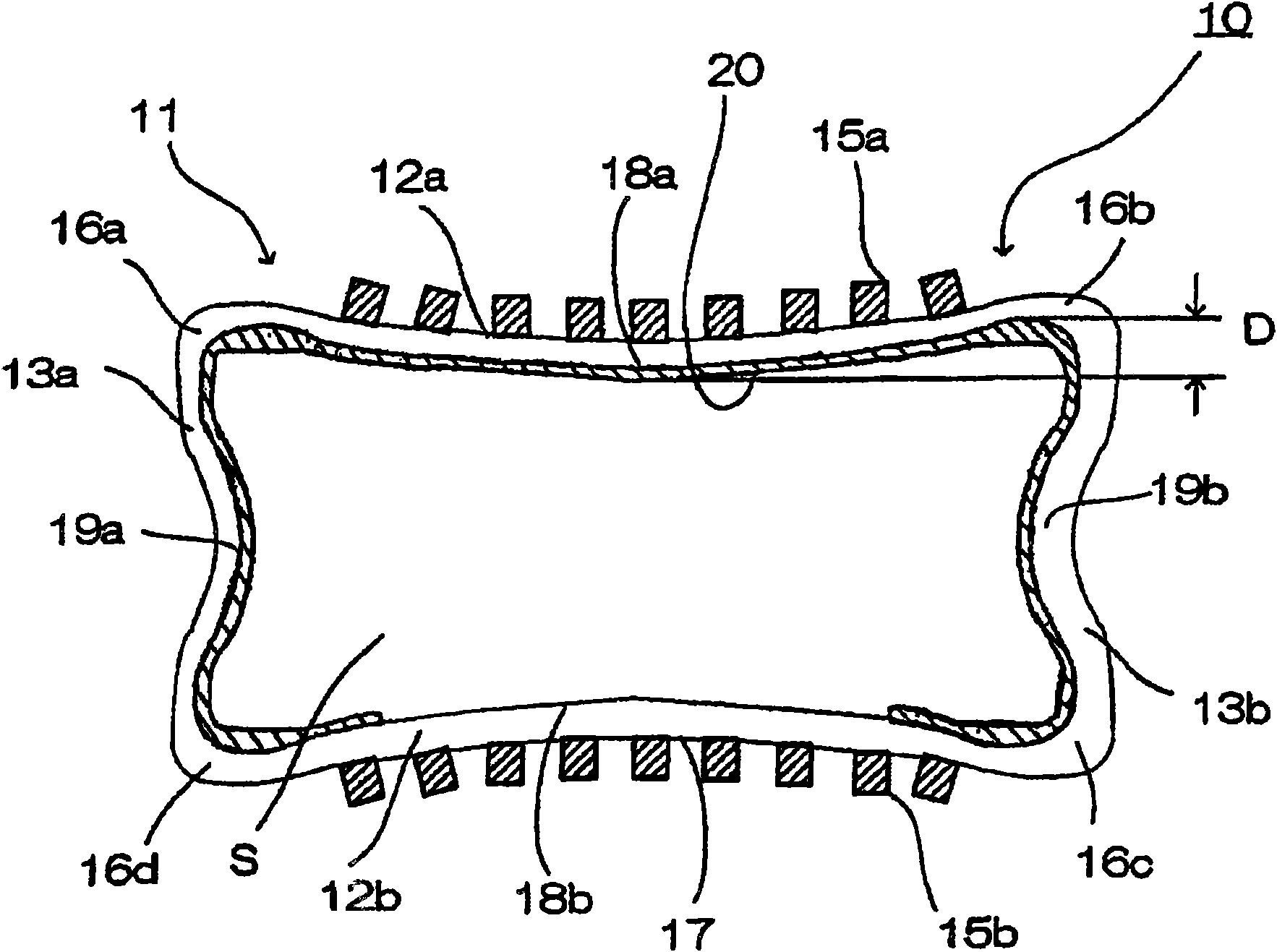

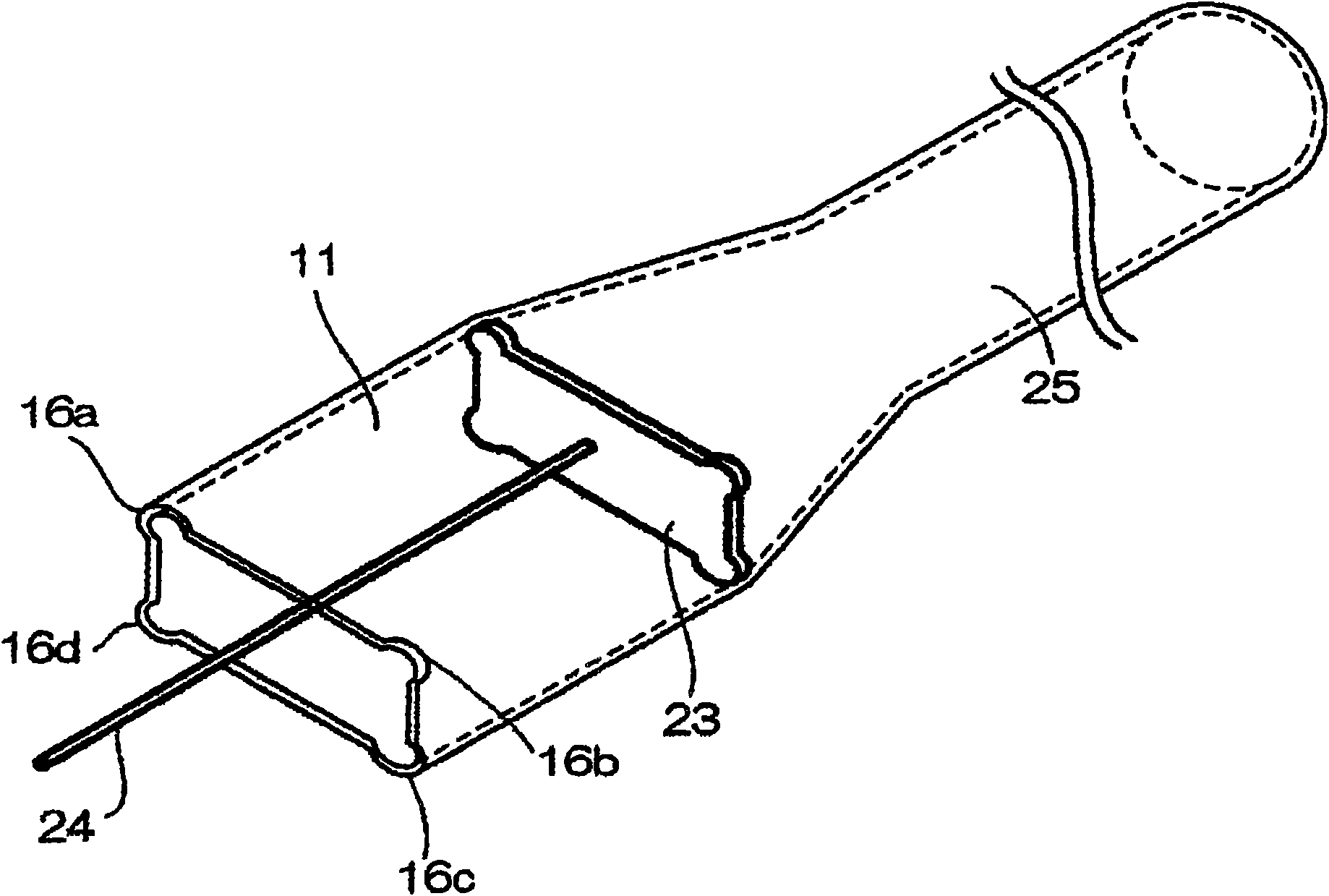

[0023] figure 1 It is an explanatory sectional view showing a schematic configuration of an example of the excimer lamp 10 of the present invention, figure 1 (a) is a cross-sectional view showing a section along the longitudinal direction of the discharge vessel 11, figure 1 (b) means figure 1 (a) A-A line sectional view.

[0024] The excimer lamp 10 is equipped with a discharge vessel 11 having a rectangular cross-section and a hollow elongated discharge vessel 11 whose both ends are hermetically sealed and a discharge space S is formed inside. There is xenon. Here, the enclosing amount of xenon gas is such that the pressure is within a range of, for example, 10 to 60 kPa.

[0025] The discharge vessel 11 is made of silica glass such as synthetic quartz glass that transmits vacuum ultraviolet light well, and also functions as a dielectric.

[0026] In discharge vessel 11, long side surfaces 12a, 12b made of long plate glass are arranged to face each other, and short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com