Floating signal contact element and electric connector using the same

A technology of electrical connectors and contacts, which is applied to the device for joining/disconnecting connected parts, two-part connecting device, connection, etc., can solve the problems of large volume, complex matching structure, and difficult manufacture of signal contacts, and achieve the realization of Connected or disconnected, improved anti-vibration, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

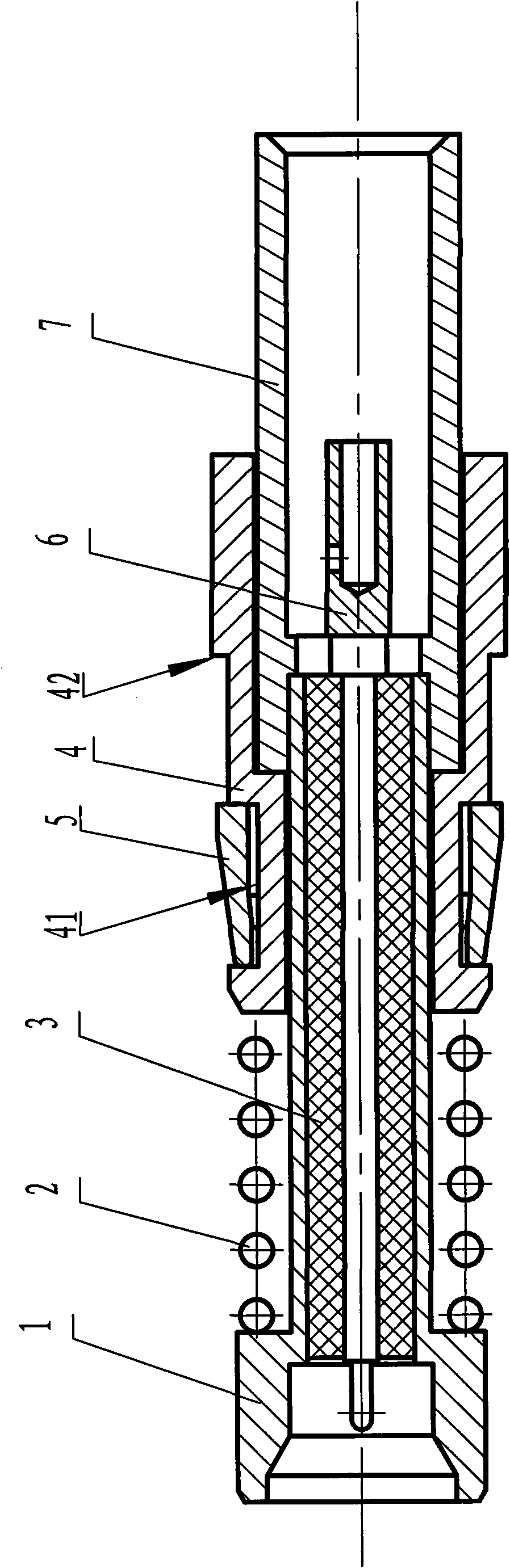

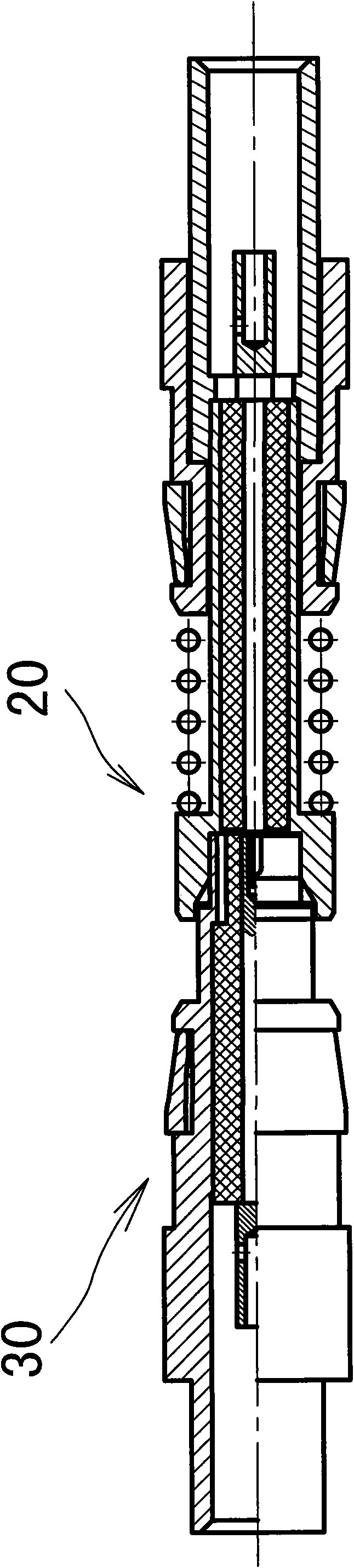

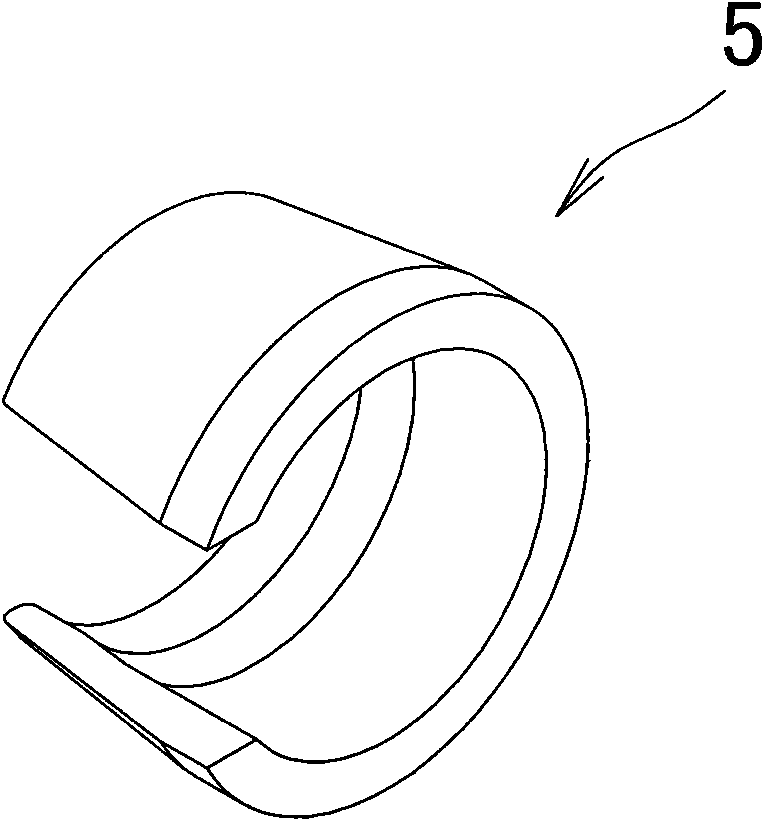

[0021] Such as figure 1 , figure 2 , image 3 As shown, the embodiment of the floating signal contact of the present invention is a high-frequency socket contact, including a floating outer conductor 1 with a through hole inside, and a sleeve-shaped insulator is installed in the through hole inside the floating outer conductor 1 3. The inner conductor 6 is installed in the inner sleeve hole of the insulator 3, and one end of the floating outer conductor 1 is a plug-in end for plugging in with an adapted high-frequency pin contact, and the other end is mated and fixed in a Other radio frequency circuits are connected into the rear sleeve 7, and the front end surface of the rear sleeve 7 forms a second annular step surface on the periphery of the junction of the outer wall of the floating outer conductor 1. The outer wall of the floating outer conductor 1 close to the plug-in end is provided with a ring platform to form a first annular step surface, and the outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com