Antiwear chain

一种耐磨性、链条的技术,应用在耐磨性链条领域,能够解决无法密合性确保产品品质、晶粒粗化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

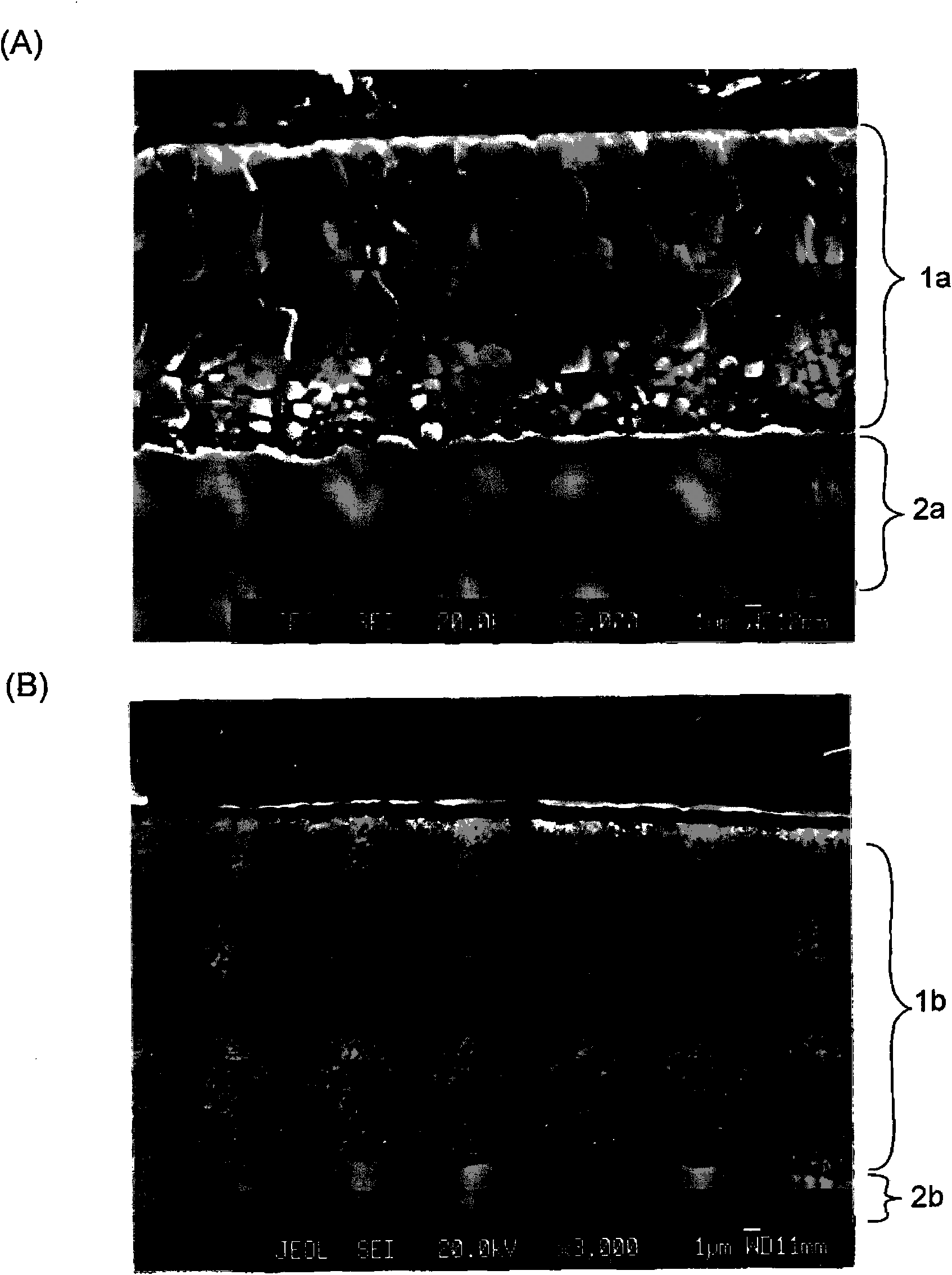

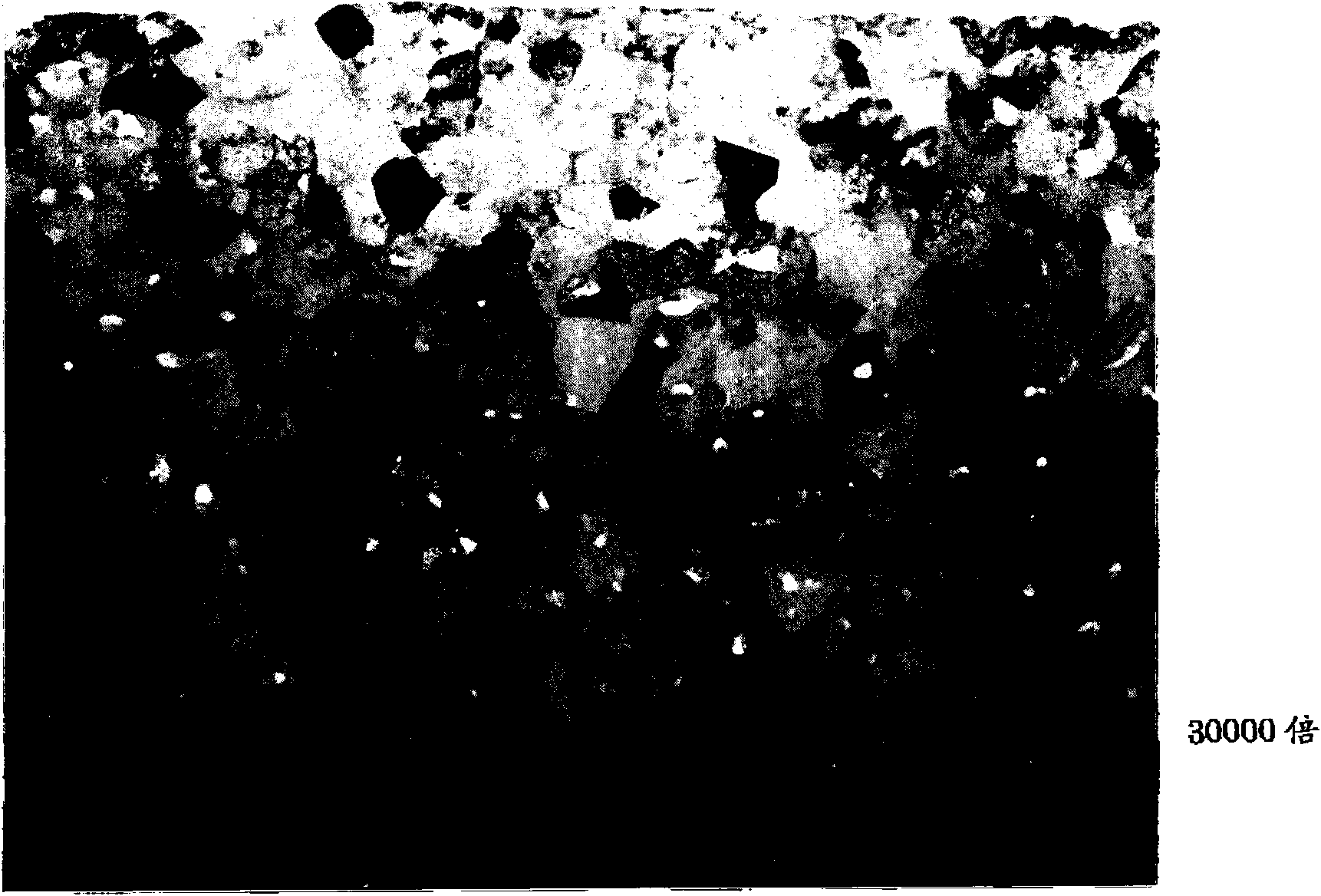

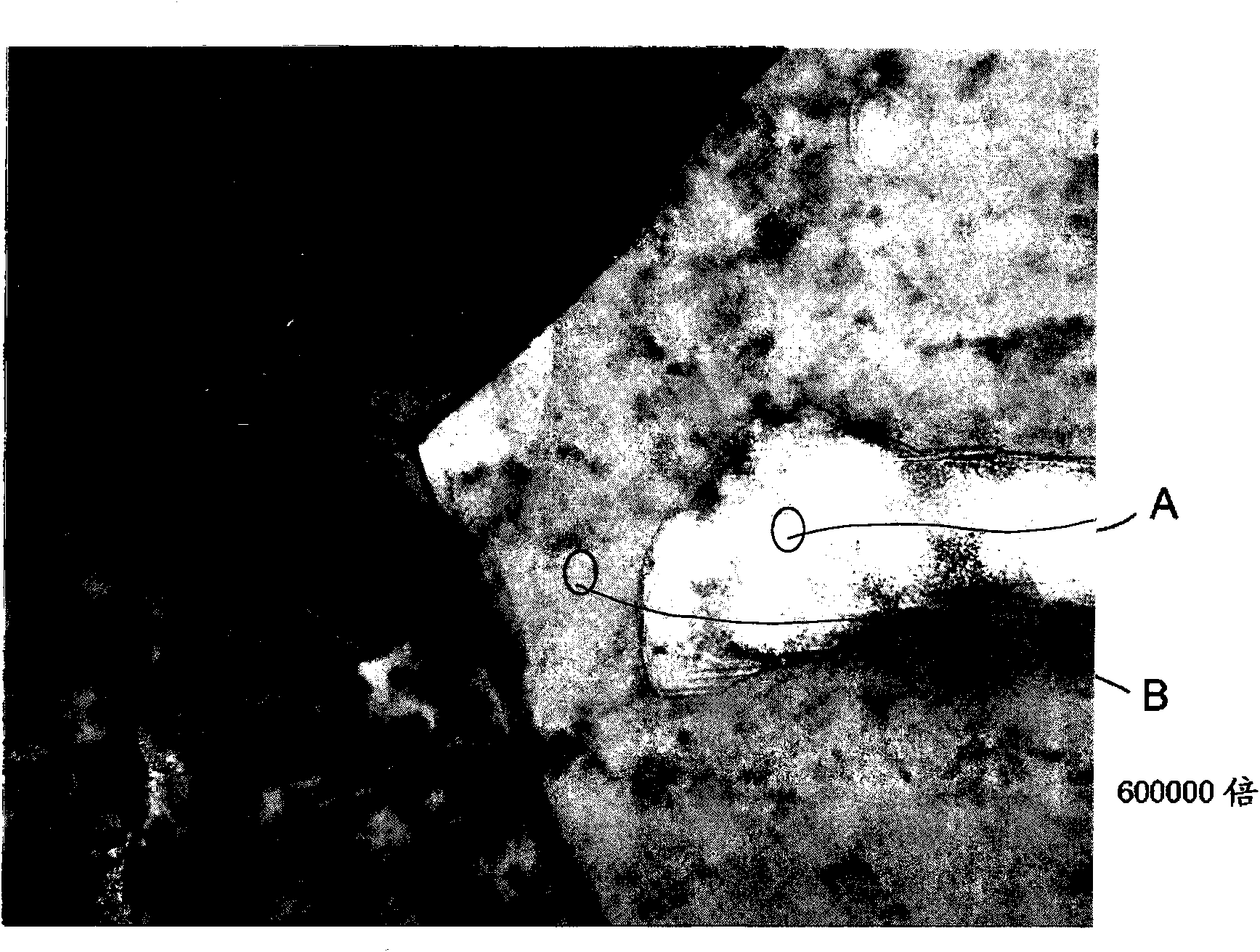

[0027] Embodiments of the present invention will be described below. The chain of the present invention is used for all power transmission chains such as known roller chains and silent chains, and is particularly suitable for chains used in engines such as timing chains.

[0028] Regarding the roller chain, the pin is inserted into the bushing to connect the shaft link and the roller link in a ring shape, and the roller is loosely fitted in the bushing. The pin is used for the shaft link. It is obtained by connecting both ends of two shafted links, and the roller link is obtained by similarly connecting both ends of two roller links with a bushing. In addition, regarding the silent chain, the guide trains and the joint trains are connected circularly by pin shafts fixed on the above-mentioned guide links. The hinged row does not have the above-mentioned guide links but only consists of toothed links.

[0029] In addition, at each buckling of the chain, a sliding contact move...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com