Ultrafine particle deduster

A dust collector and particle technology, which is applied in the field of air pollution control and environmental protection equipment, can solve the problems of environmental pollution, small size and large number of particles, and achieve the effect of reducing the harm of pollution accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

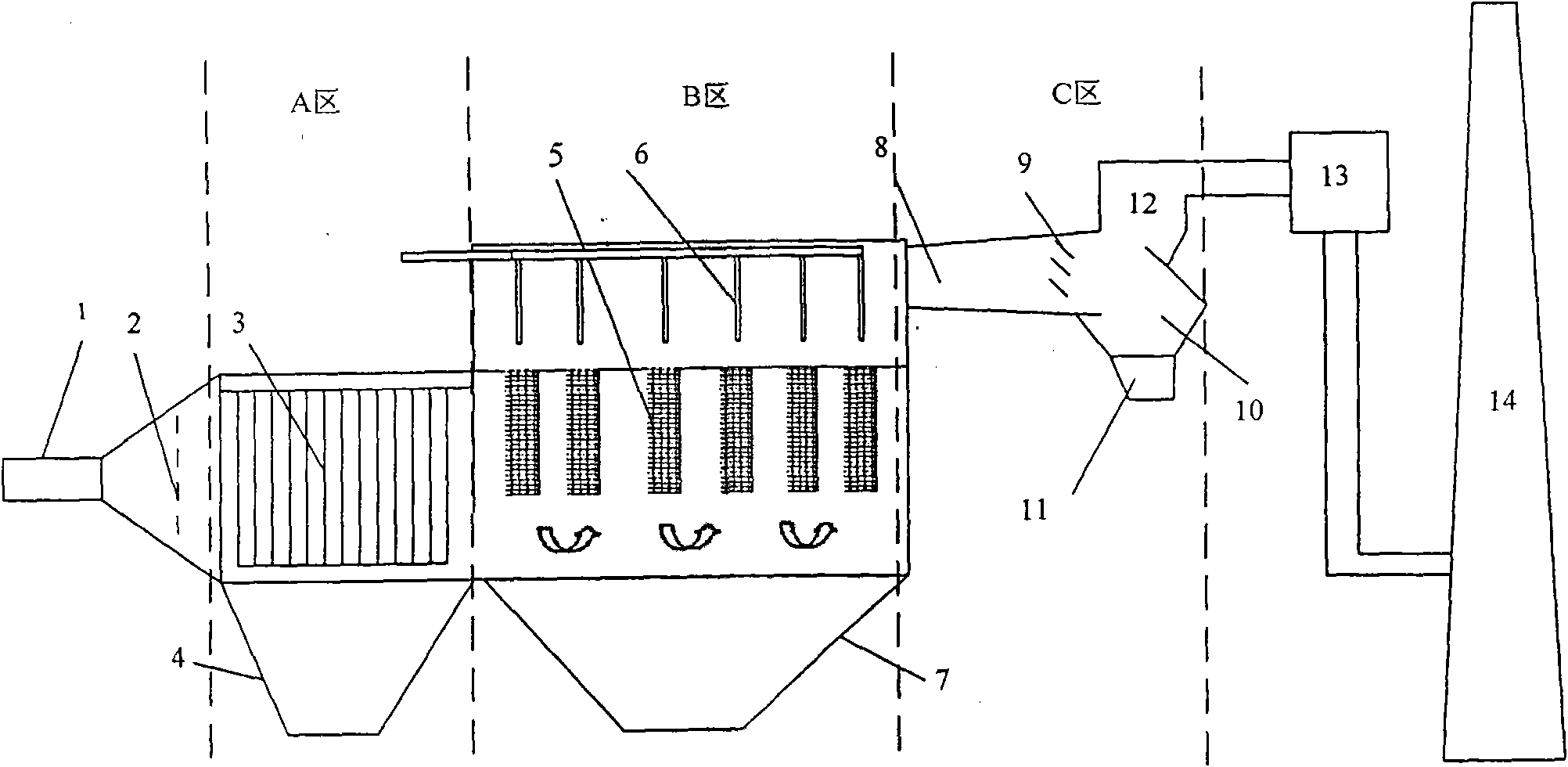

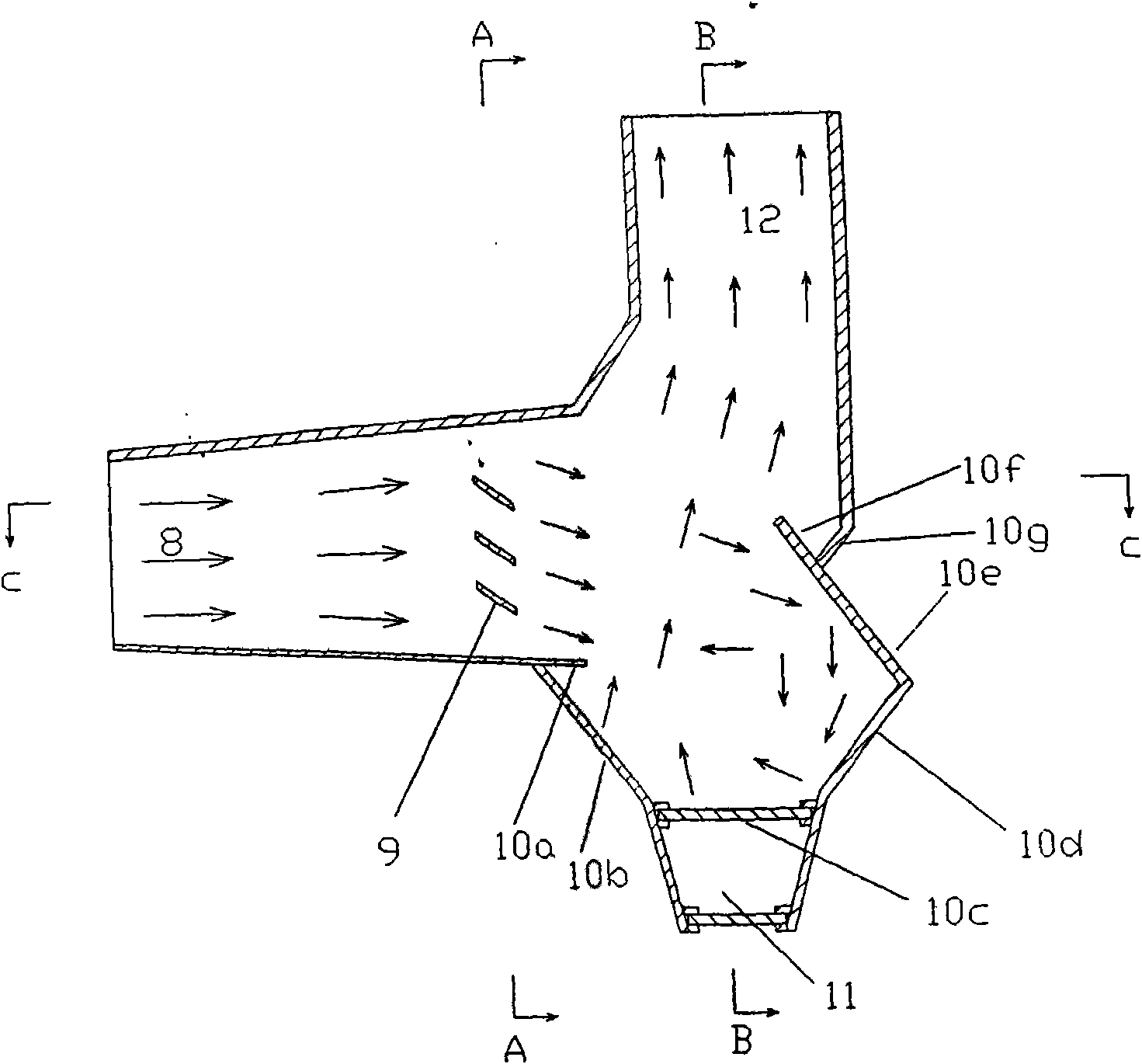

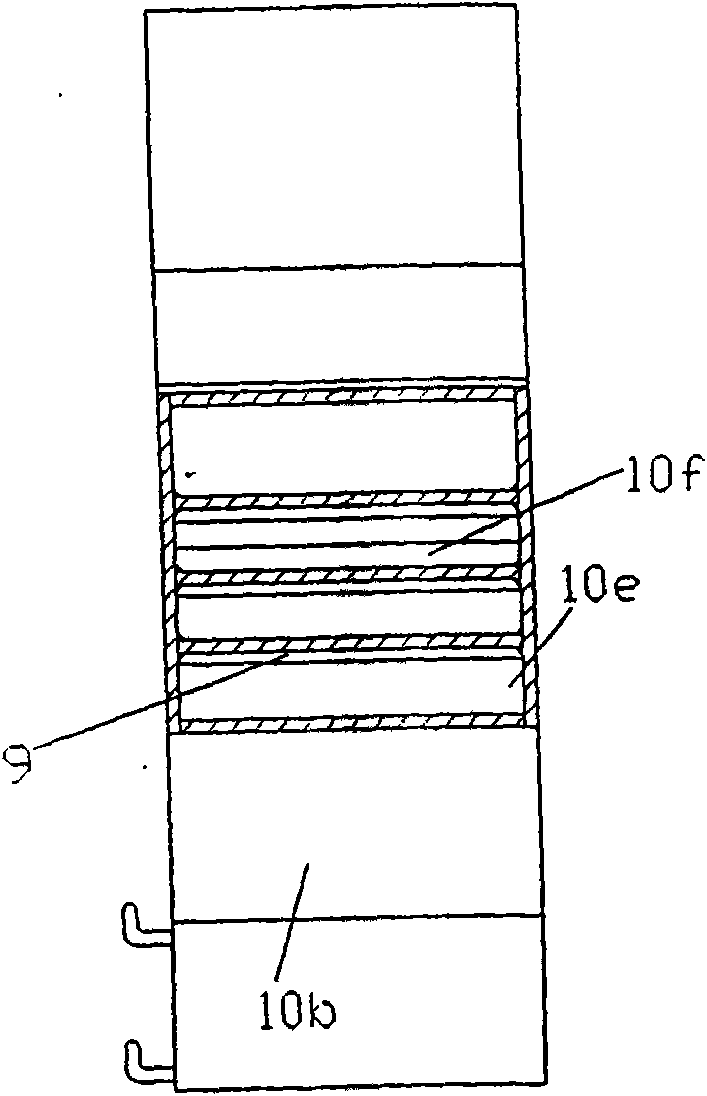

[0030] See figure 1 , The fine particle dust collector includes a smoke and dust inlet 1, an electrostatic dust removal mechanism, a filter bag dust removal mechanism, an induced draft fan 13 and a chimney 14 connected in sequence. A uniform flow plate 2 is provided in the smoke and dust inlet 1; a dust collecting plate 3 is evenly distributed in the electrostatic dust removal mechanism, and an electrostatic dust hopper 4 is arranged at the bottom; the filter bag dust removal mechanism includes uniformly arranged filter bags 5 and 5 The material is anode or cathode fiber. The top of the filter bag dust removal mechanism is equipped with a reverse pulse cleaning valve 6 and the bottom is equipped with an ash hopper 7; a turbulent vortex mechanism is set between the outlet of the filter bag dust removal mechanism and the inlet of the induced draft fan The turbulent vortex mechanism includes a turbulent vortex chamber, a smoke inlet pipe 8 and a smoke outlet pipe 12.

[0031] See f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com