X-shaft transmission system for modifying planing machine into milling planer

A technology of gantry milling machine and gantry planer, which is applied in the direction of driving devices, manufacturing tools, metal processing machinery parts, etc. It can solve the problems of large backlash in X-axis transmission, reduce the rigidity of the transmission system, and lower requirements for positioning rigidity. The effect of large clearance, improved machining accuracy, and low material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

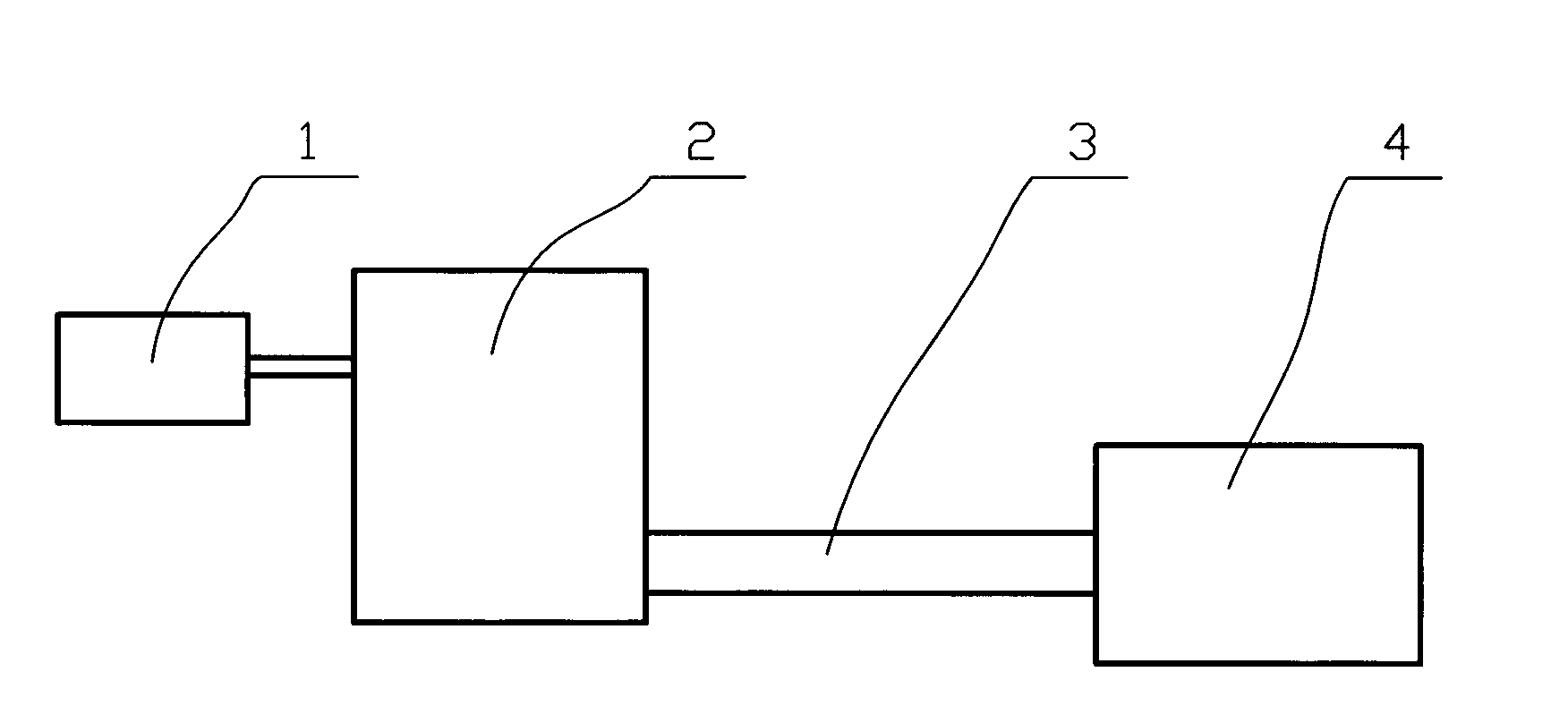

[0026] exist figure 1 , we can see that when the servo motor 1 starts to rotate, if the figure 1 The gears in the gear box 4 in the middle are well matched, then it is required to start from the output shaft of the motor and the input shaft of the gearbox, the middle gearbox 2, the large transmission shaft 3 and the large transmission shaft 3 and There must be better transmission rigidity between the gear shafts 7, so as to avoid the occurrence of crawling during the operation of the whole system.

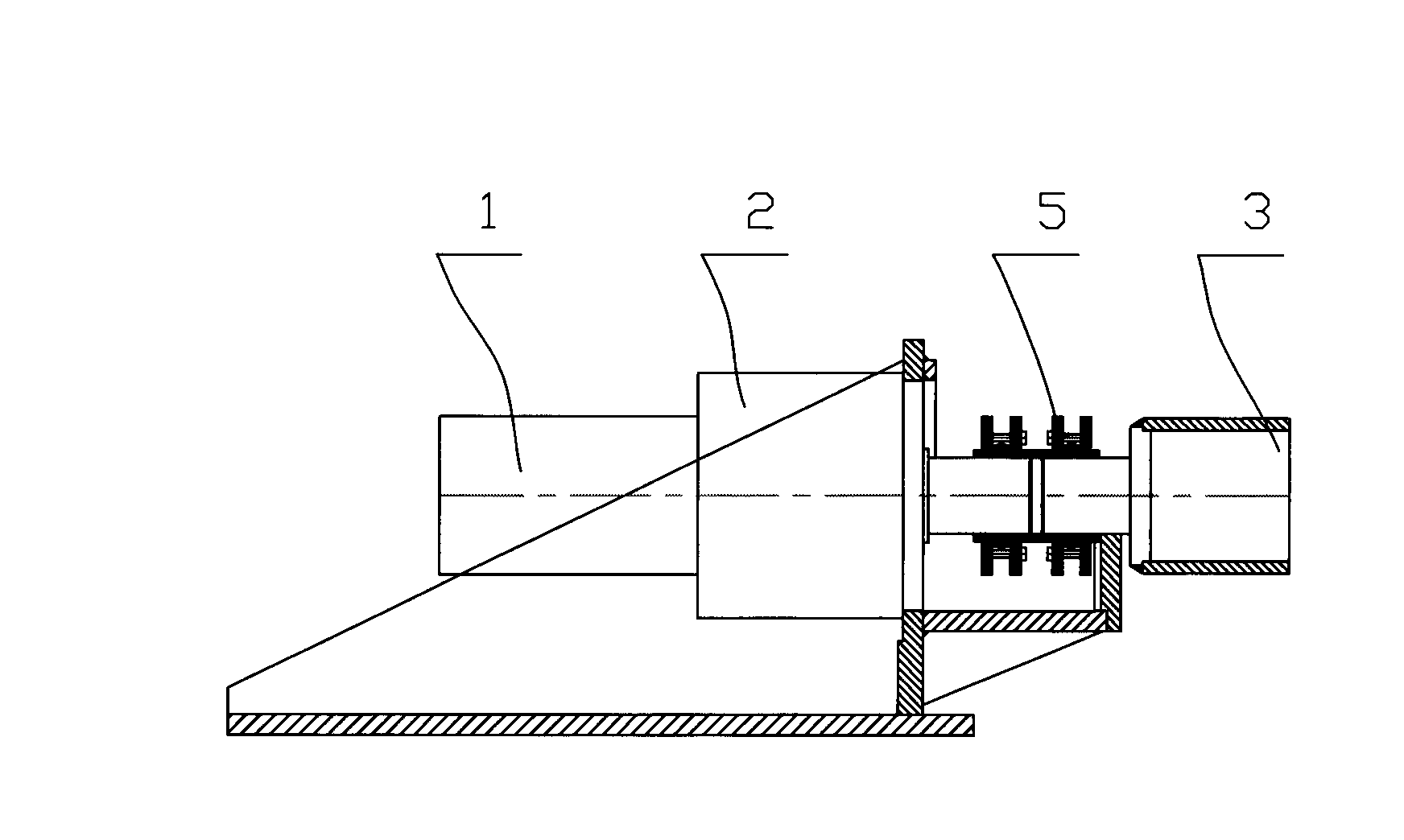

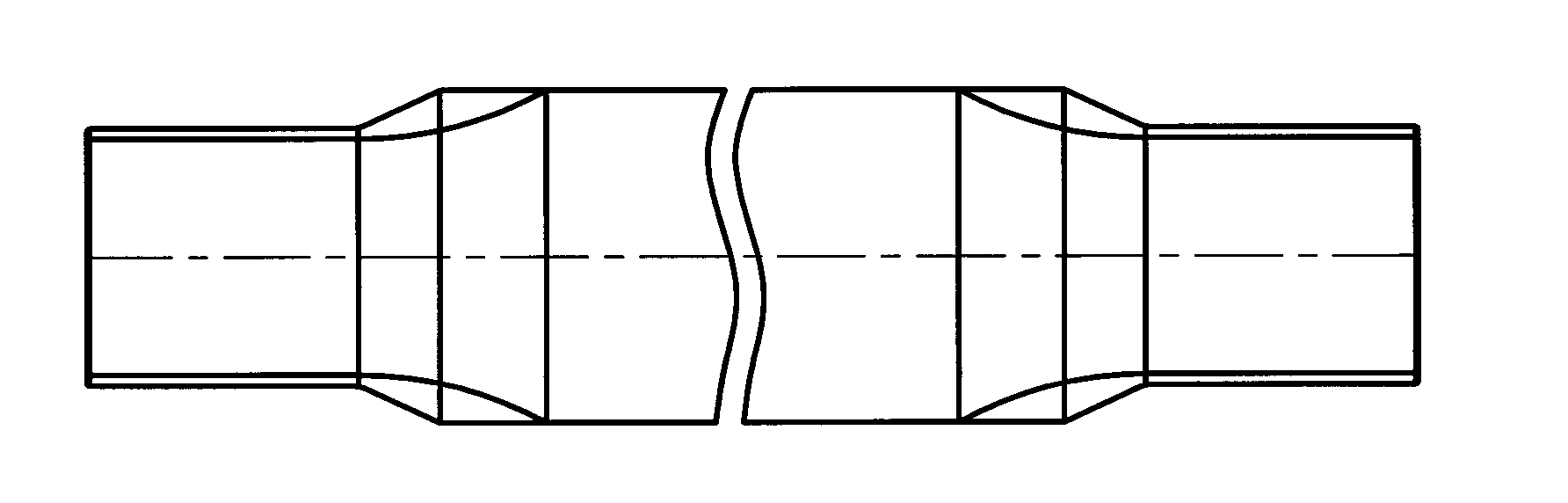

[0027] Such as figure 2 As shown, the output shaft of servo motor 1 and the input shaft of gearbox 2 are connected through expansion sleeves, which increases the transmission rigidity of the two parts. The output shaft of gearbox 2 and the shaft end of the large transmission shaft pass through the first An expansion sleeve 5 is connected, which also incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com