Hydraulic tamping briquette device with heating device

A heating device and a technology for tamping coal, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems affecting the production efficiency of pressed coal cakes, affecting the production and quality of coke, and freezing coal powder, and achieves accelerated The pace of enterprise economic construction, the effect of improving the level of mechanization and automation, and the effect of surface leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

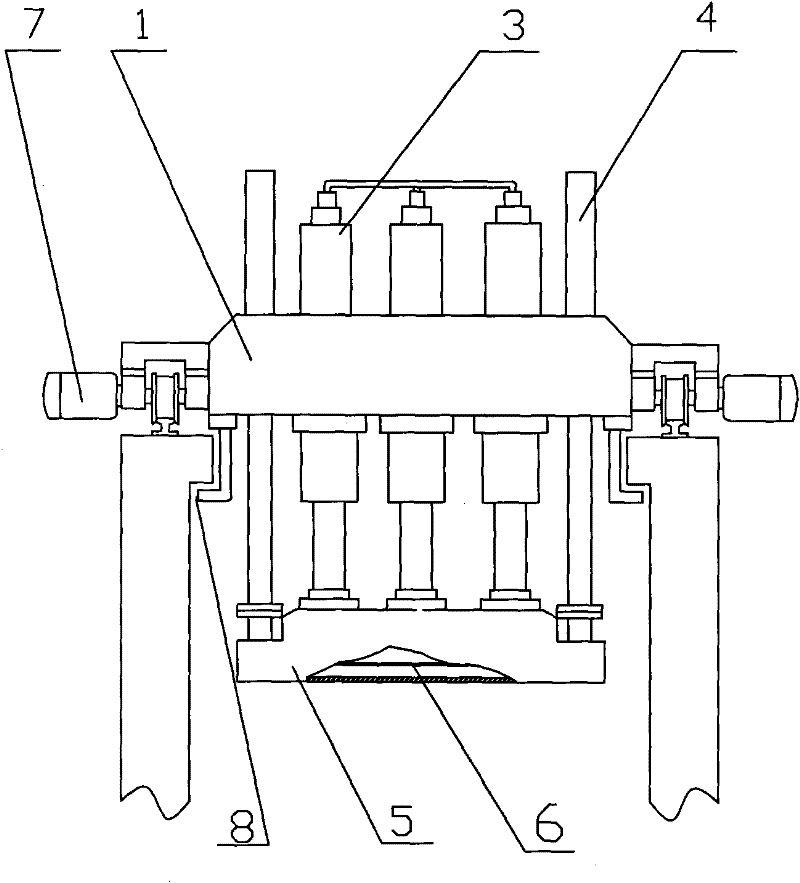

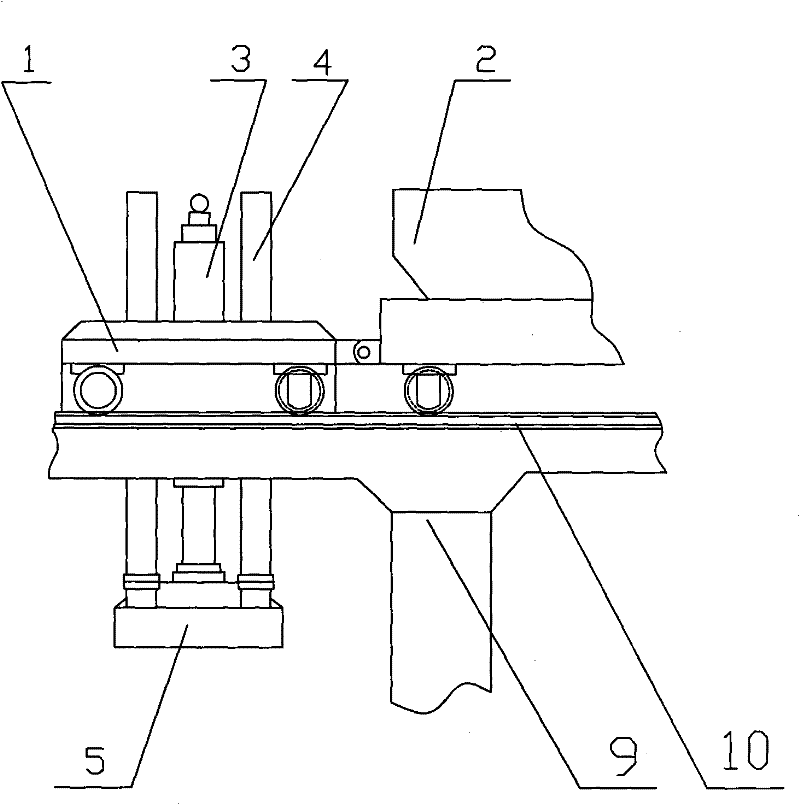

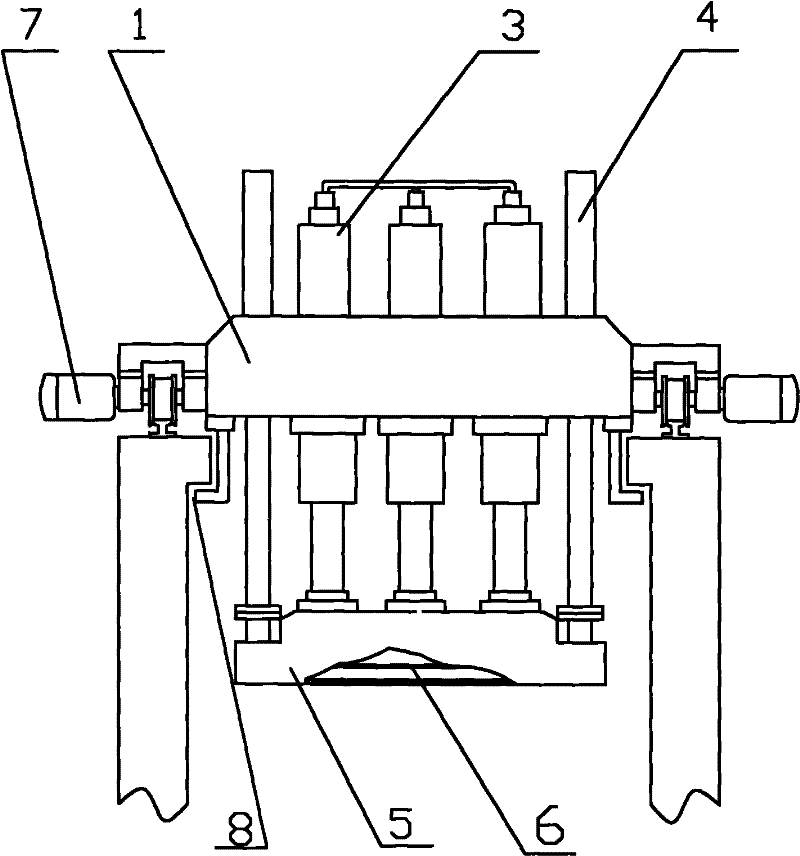

[0011] Such as figure 1 , figure 2 As shown, the hydraulic tamping briquette device with a heating device includes a coal pressing frame 1 and a coal distribution trolley 2, and is characterized in that the coal pressing frame is also equipped with two pairs of wheels. The coal trolley is connected by connecting plate hinges; the hydraulic motors 7 for driving the wheels are installed on both sides of the coal pressing frame; the coal pressing cylinder 3 is fixed in the middle of the coal pressing frame through a flange, Guide hole, the guide hole is equipped with a guide sleeve and a guide rod 4; the lower end of the coal pressing oil cylinder and the guide rod is equipped with a coal pressing plate 5, and a heating device 6 is also installed at the bottom of the pressing coal pressing plate inside; The bottom of both sides of the coal press frame is also equipped with locking hooks 8 for fixing the coal press frame 1 .

[0012] The heating device is composed of four U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com