Reversing mechanism for bottle cap container loader

A technology of a cover packing machine and a reversing mechanism, which is applied in the mechanical field, can solve problems such as error efficiency, etc., and achieve the effects of improving the packing efficiency and accurate reversing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

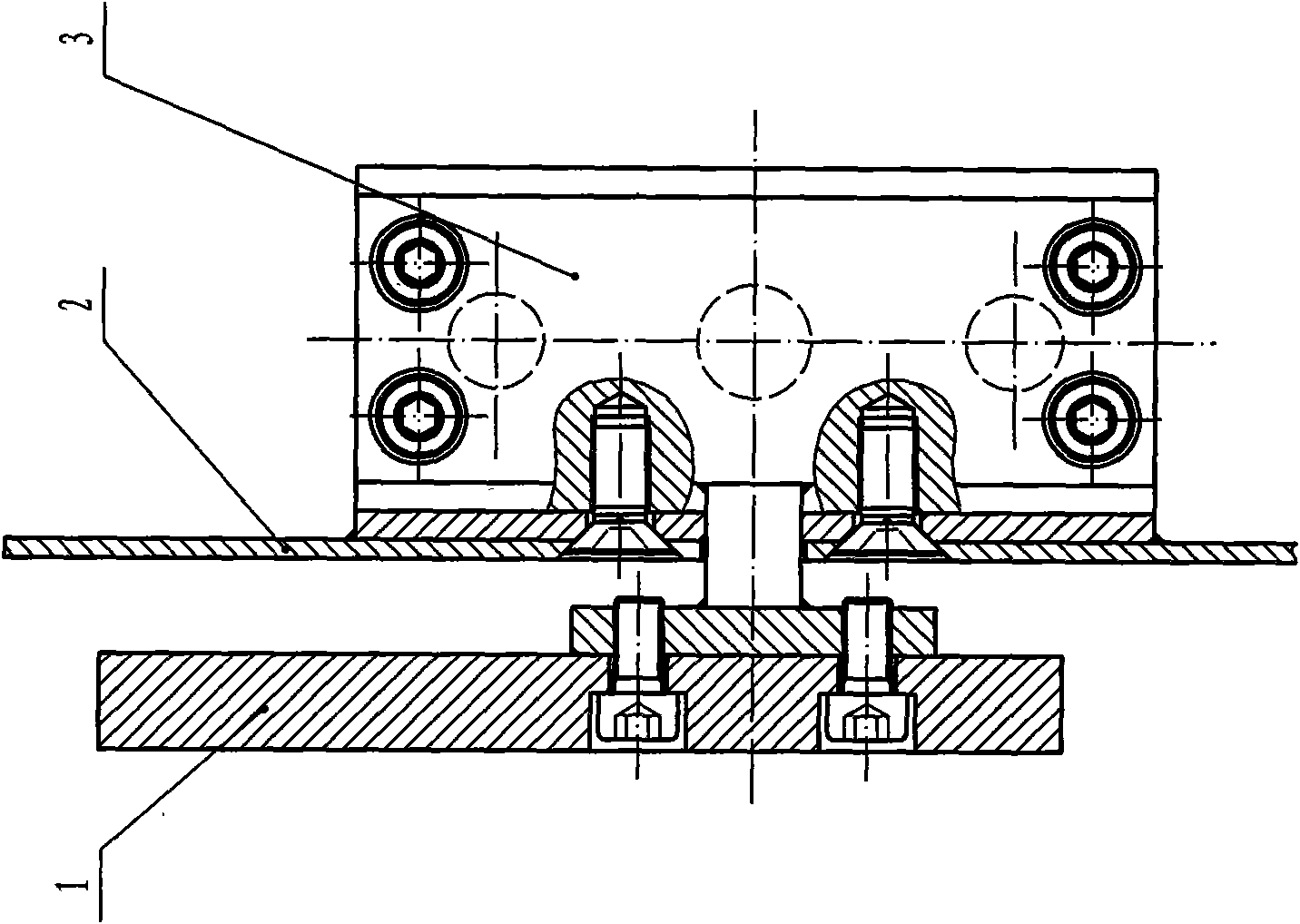

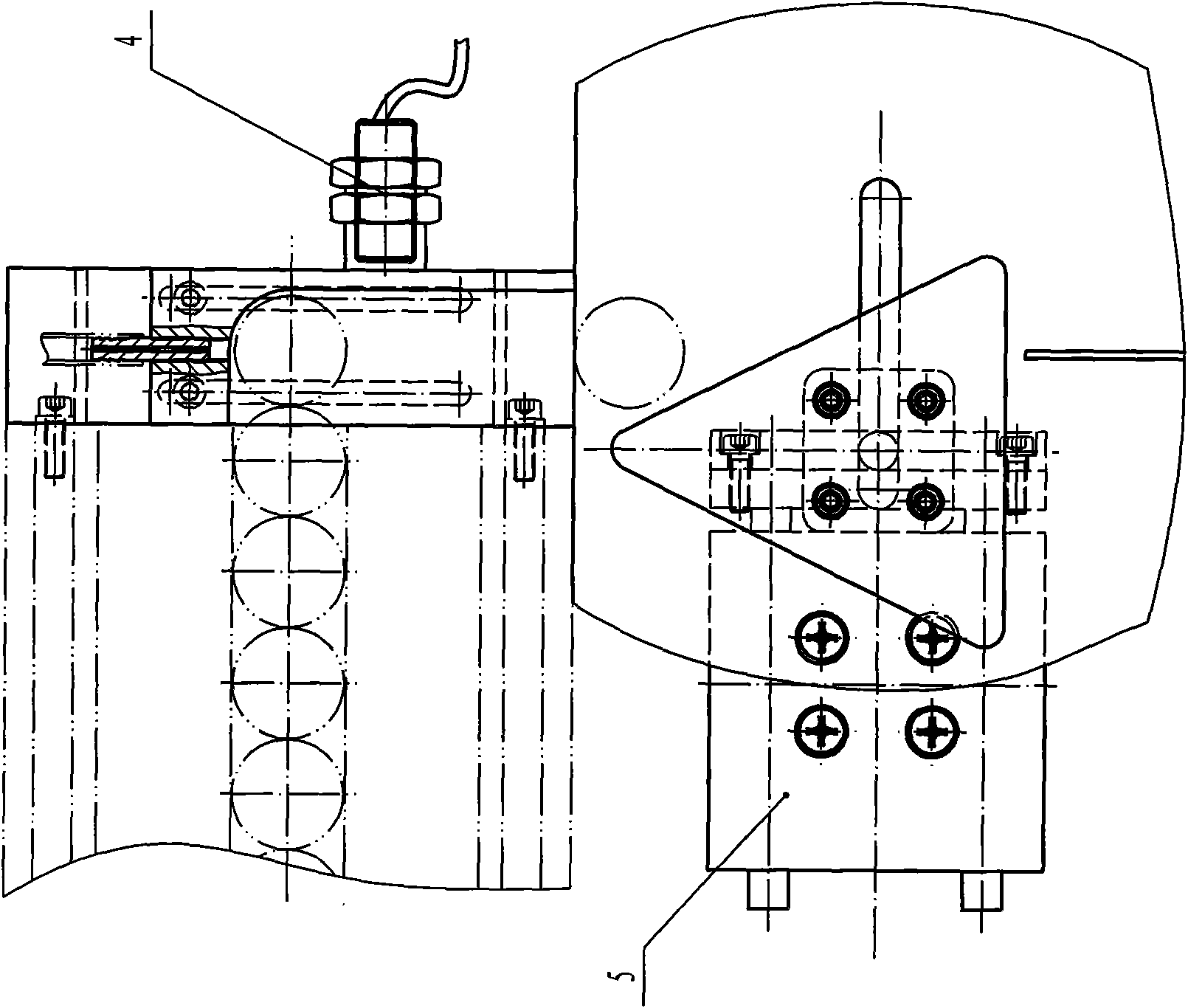

[0010] The present invention will be further described below in conjunction with the accompanying drawings: a reversing mechanism of a bottle cap packing machine, including a counting sensor 4 connected to a bottle cap conveyor, a workbench 2, a guiding cylinder 5 is set below the workbench 2, and the guide The cylinder 5 is connected with the propeller 3, and the commutator 1 is arranged above the workbench 2, and the commutator 1 is connected with the propeller 3.

[0011] When the counting sensor 4 counts up to the set value, the guide cylinder 5 acts once, and the propeller 3 drives the commutator 1 to push the bottle cap to a packing area of the workbench 2, and the other packing area can continue packing Action; when the next counting work is completed, the commutator 1 pushes the bottle cap to another boxing area of the workbench. So back and forth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com