Novel turbocharger

A turbocharger, a new type of technology, applied in the direction of machines/engines, gas turbine devices, engine components, etc., to simplify the sealing system, reduce the difficulty of machining, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

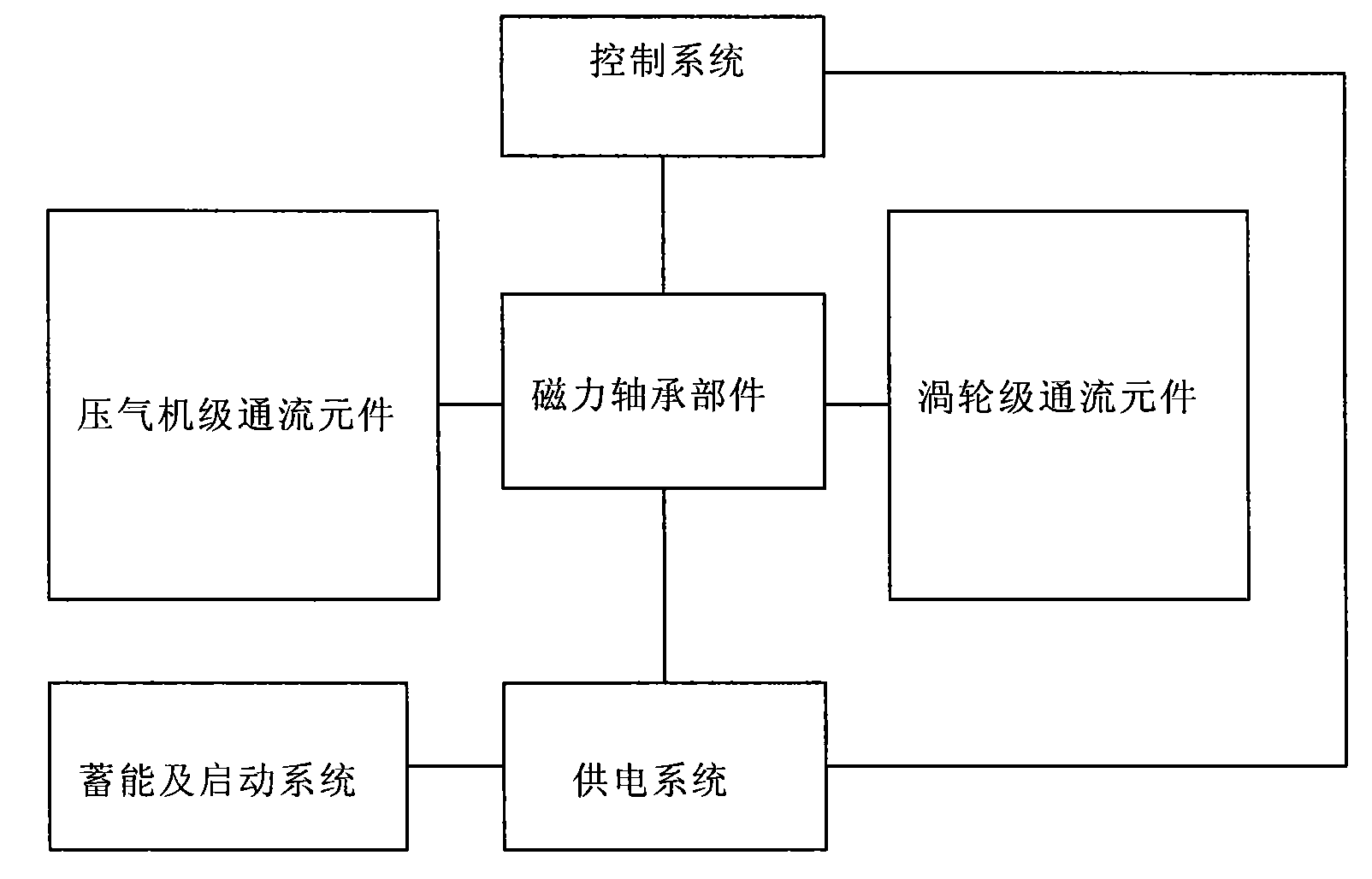

[0017] Such as figure 2 As shown, the structure of the new turbocharger module is: the compressor stage flow element and the turbine stage flow element are respectively located on both sides of the magnetic bearing component, and the compressed air component in the compressor flow element module is the compressor impeller and the turbine flow element. The power turbine in the flow element is connected by the shaft of the magnetic bearing component, which makes the shaft suspended in the center under the action of magnetic force, and the supercharger does not need oil lubrication, water cooling, or oil sealing. The compressor-level flow elements and the turbine-level flow elements form their own independent flow pipelines, and only need to seal the gases in the independent pipelines accordingly, so there are no problems such as blow-by gas, oil leakage and carbon deposits.

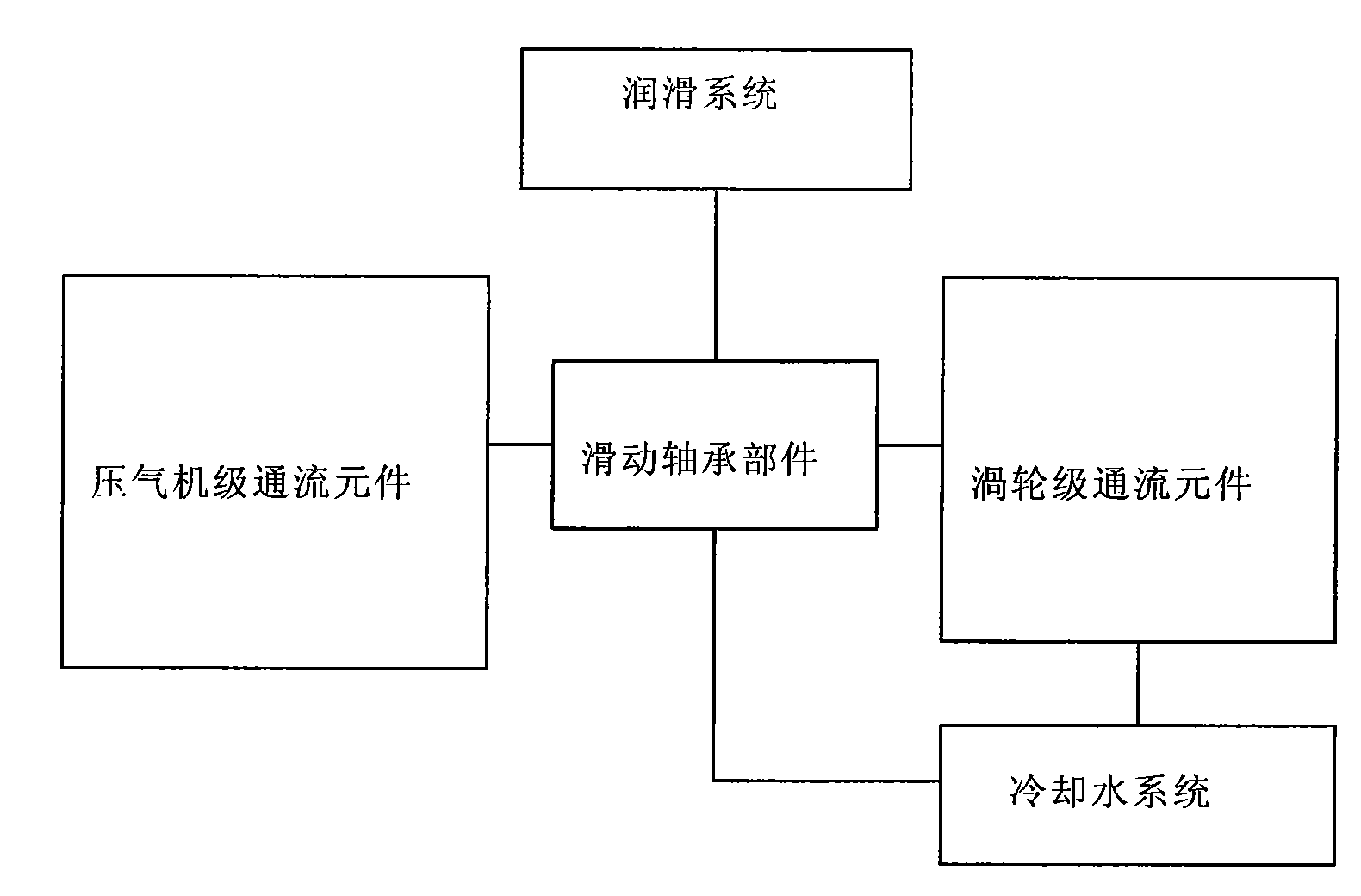

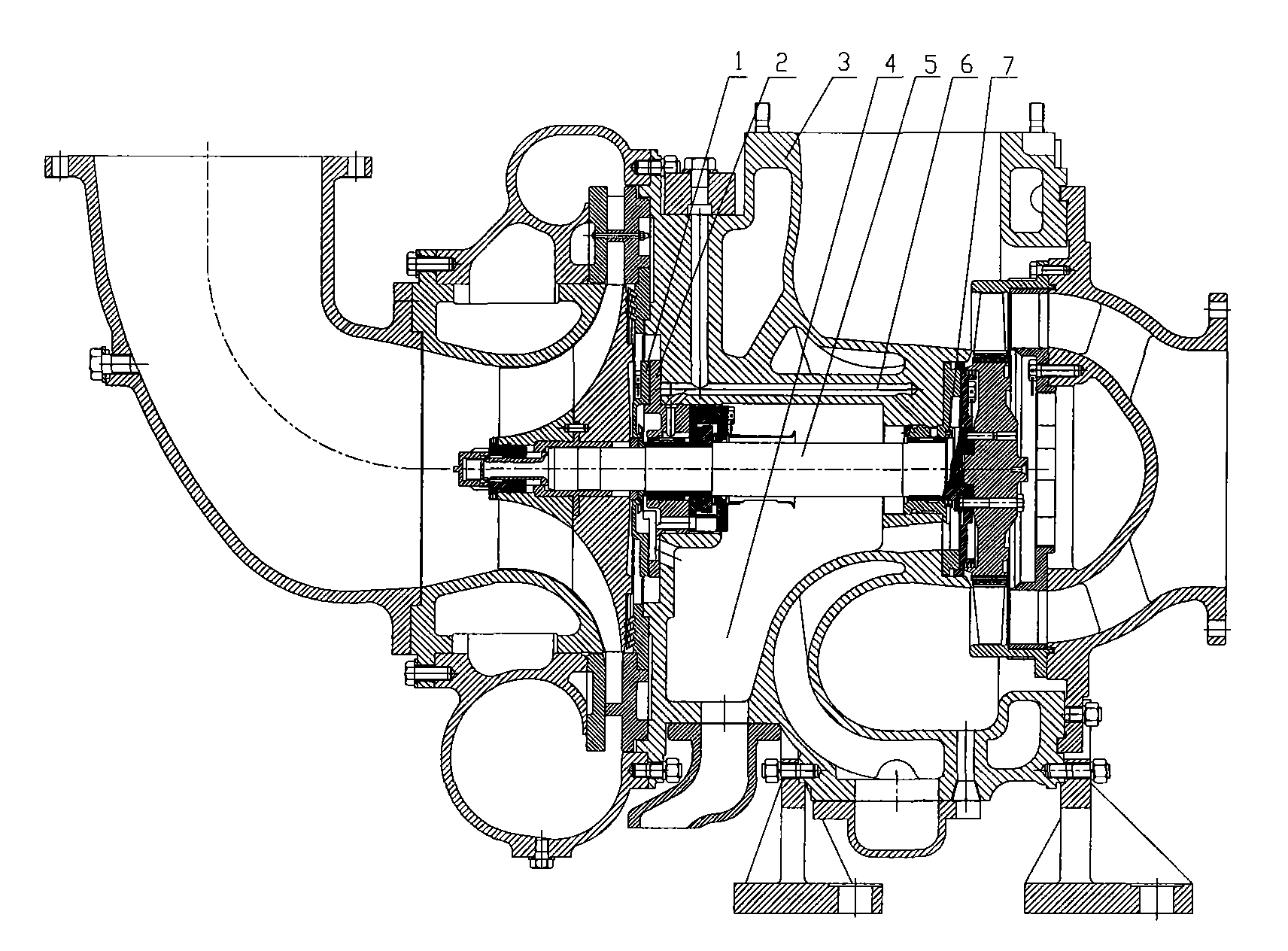

[0018] Depend on image 3 , 4 The difference between the existing turbocharger structure and the new ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com