Processing method, processing system and maintenance equipment for defects of liquid crystal display panel

A liquid crystal display panel and processing system technology, applied in the direction of image data processing, electrical digital data processing, architecture with multiple processing units, etc., can solve problems such as defects, low maintenance efficiency, and low judgment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

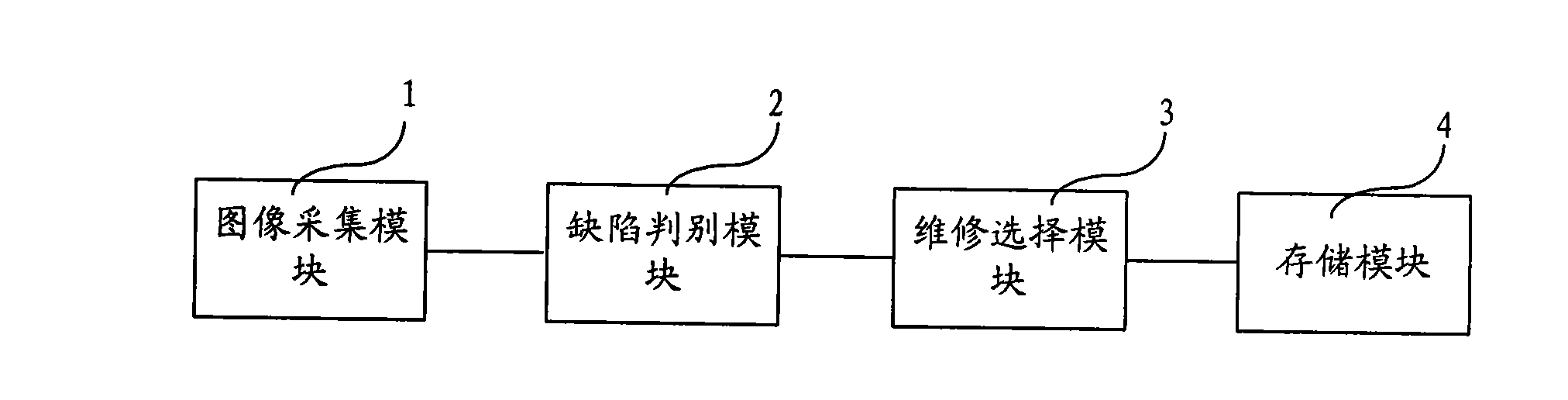

[0055] The TFT devices of the TFT-LCD repaired by the laser repair equipment in the embodiment of the present invention are usually multi-layered and multi-crossed, with high graphic complexity, and the characteristics of defects are also diverse and complex, but at the same time, the same type of liquid crystal The panel device structure is basically the same, and the TFT pattern has strong repeatability. The occurrence mechanism of each defect may require different maintenance solutions. The technical solution provided by the embodiment of the present invention can automatically judge the defect and select a maintenance solution according to the defect type for maintenance.

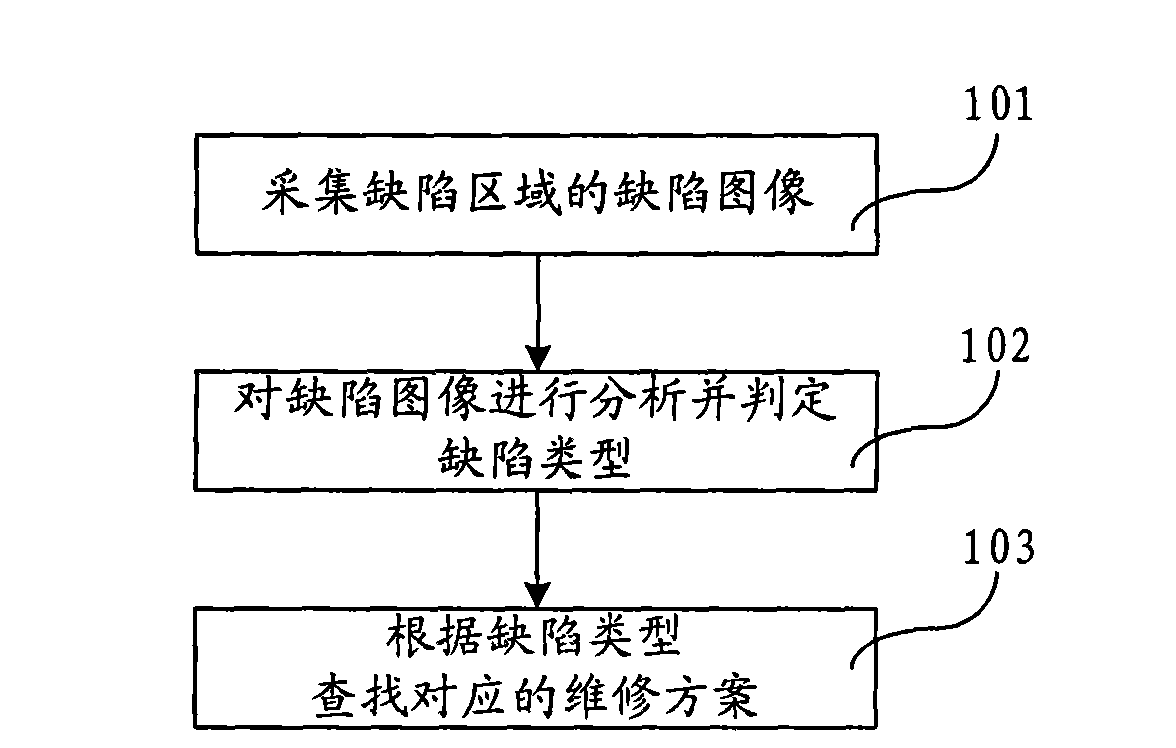

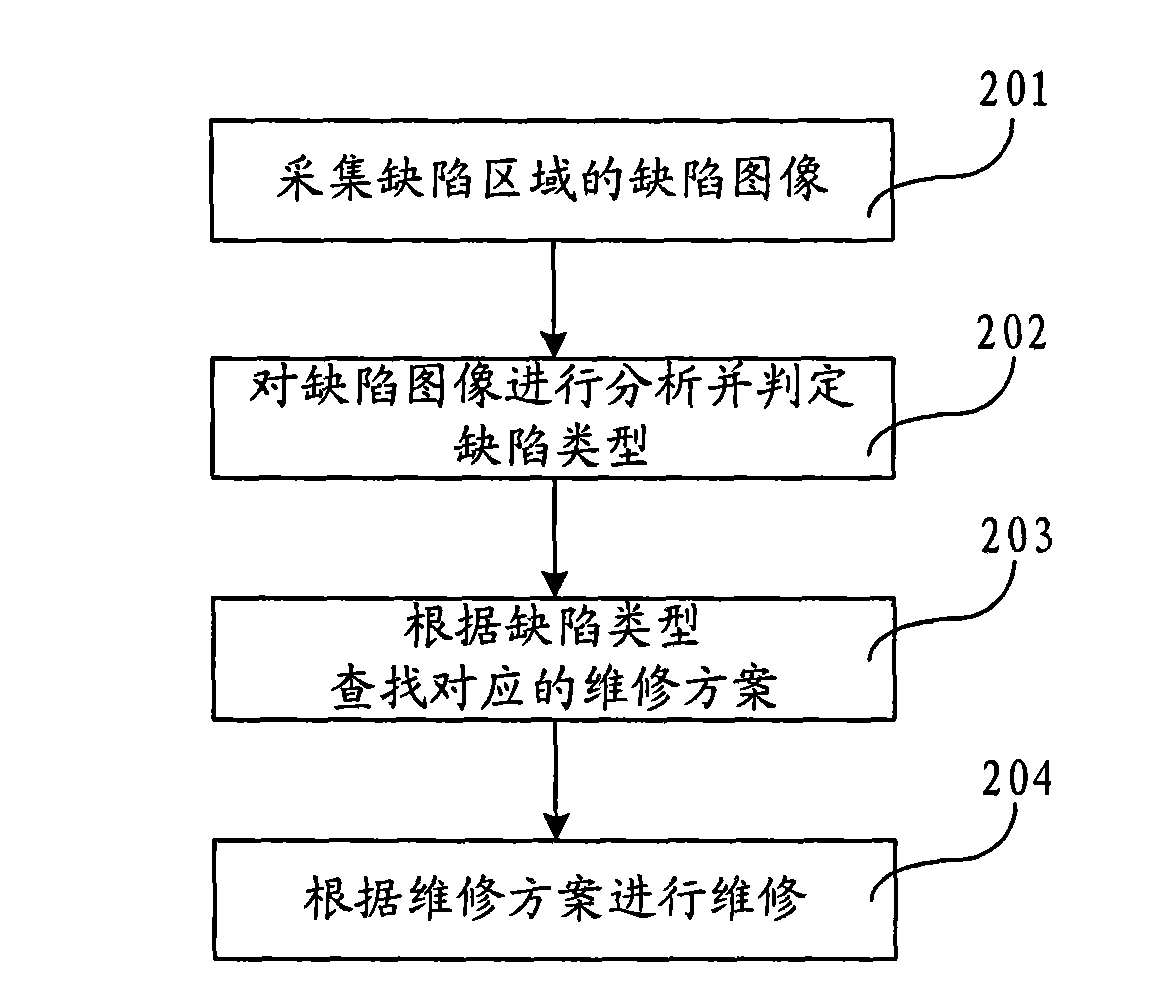

[0056] figure 1 It is a flow chart of Embodiment 1 of the method for processing liquid crystal display panel defects of the present invention, including the following steps:

[0057] Step 101, collecting defect images of defect areas on the liquid crystal display panel;

[0058] Step 102, analyzing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com