Plasma processing apparatus and plasma processing method

一种等离子体、处理方法的技术,应用在离子体处理装置领域,能够解决加大、均匀性降低等问题,达到提高均匀性、保证均匀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

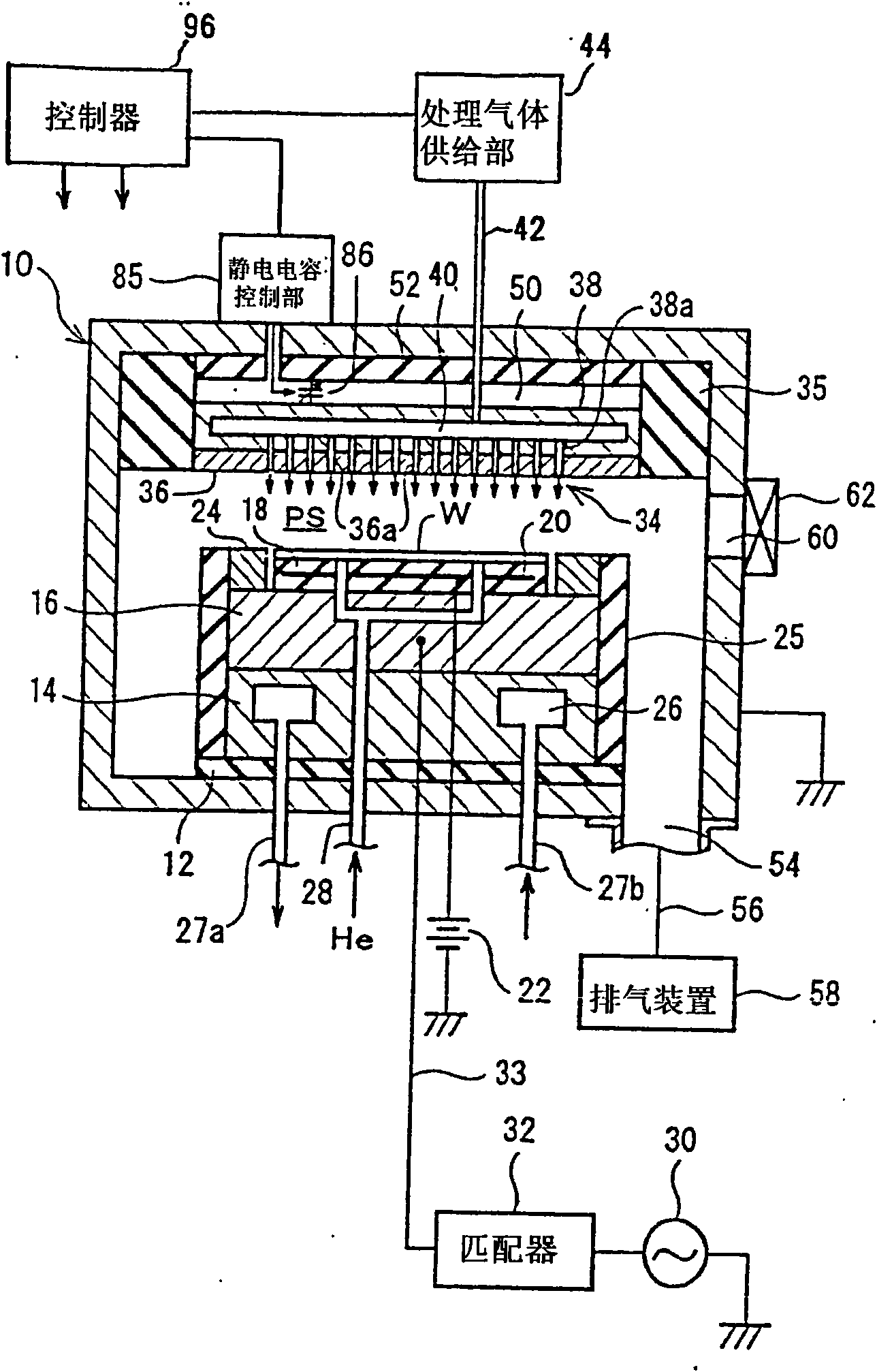

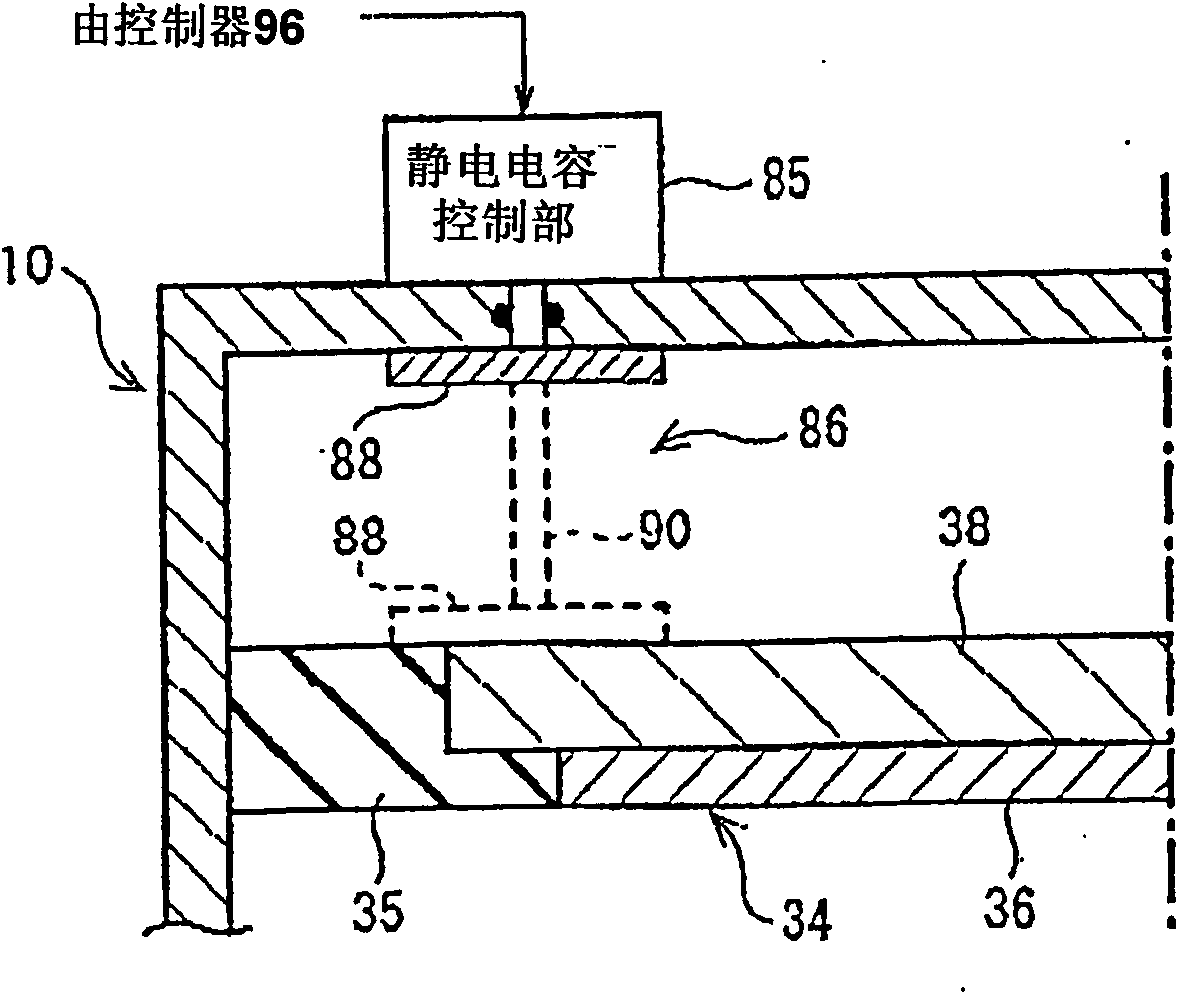

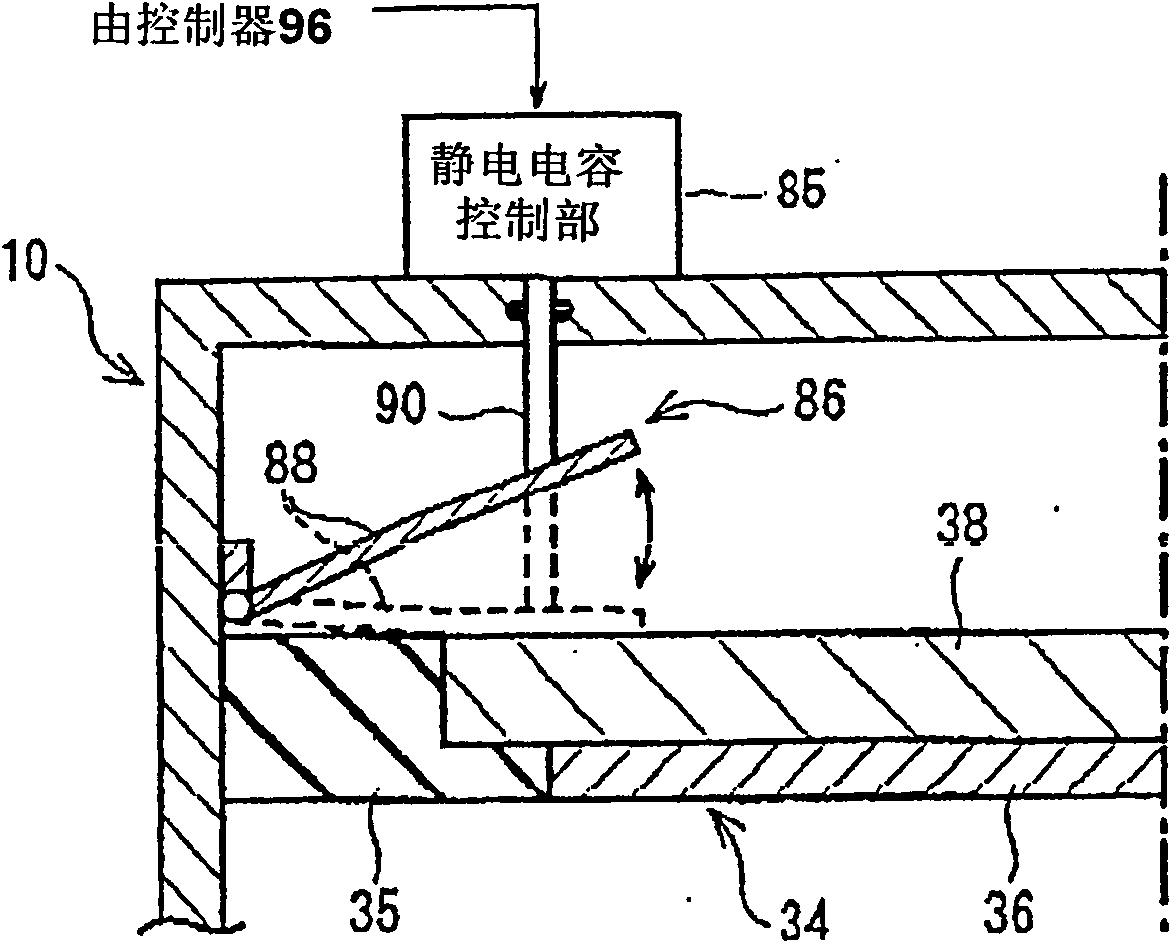

[0048] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0049] exist figure 1 In the figure, the structure of the plasma processing apparatus which concerns on one Embodiment of this invention is shown. This plasma processing apparatus is configured as a cathode-coupled capacitively coupled (parallel plate type) plasma etching apparatus, for example, having a cylindrical vacuum chamber made of aluminum whose surface is treated with an aluminum oxide film (anodized treatment). Chamber (processing container) 10 . Chamber 10 is securely grounded.

[0050] At the bottom of the chamber 10 , a cylindrical susceptor support 14 is disposed via an insulating plate 12 such as ceramics, and a susceptor 16 made of, for example, aluminum is provided on the upper surface of the susceptor support 14 . The susceptor 16 constitutes a lower electrode, on which, for example, a semiconductor wafer W is placed as a substrate to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com