Spiral type fermentation turner

The utility model relates to a mixer and a screw type technology, which is applied in the field of devices for realizing forced ventilation and oxygenation of materials, and can solve the influence of the stability and safety of the mixer, the limitation of the accumulation thickness of fermented materials, and the inability of the mixer to move normally, etc. problems, to achieve the effect of shortening the fermentation cycle, reducing energy consumption and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

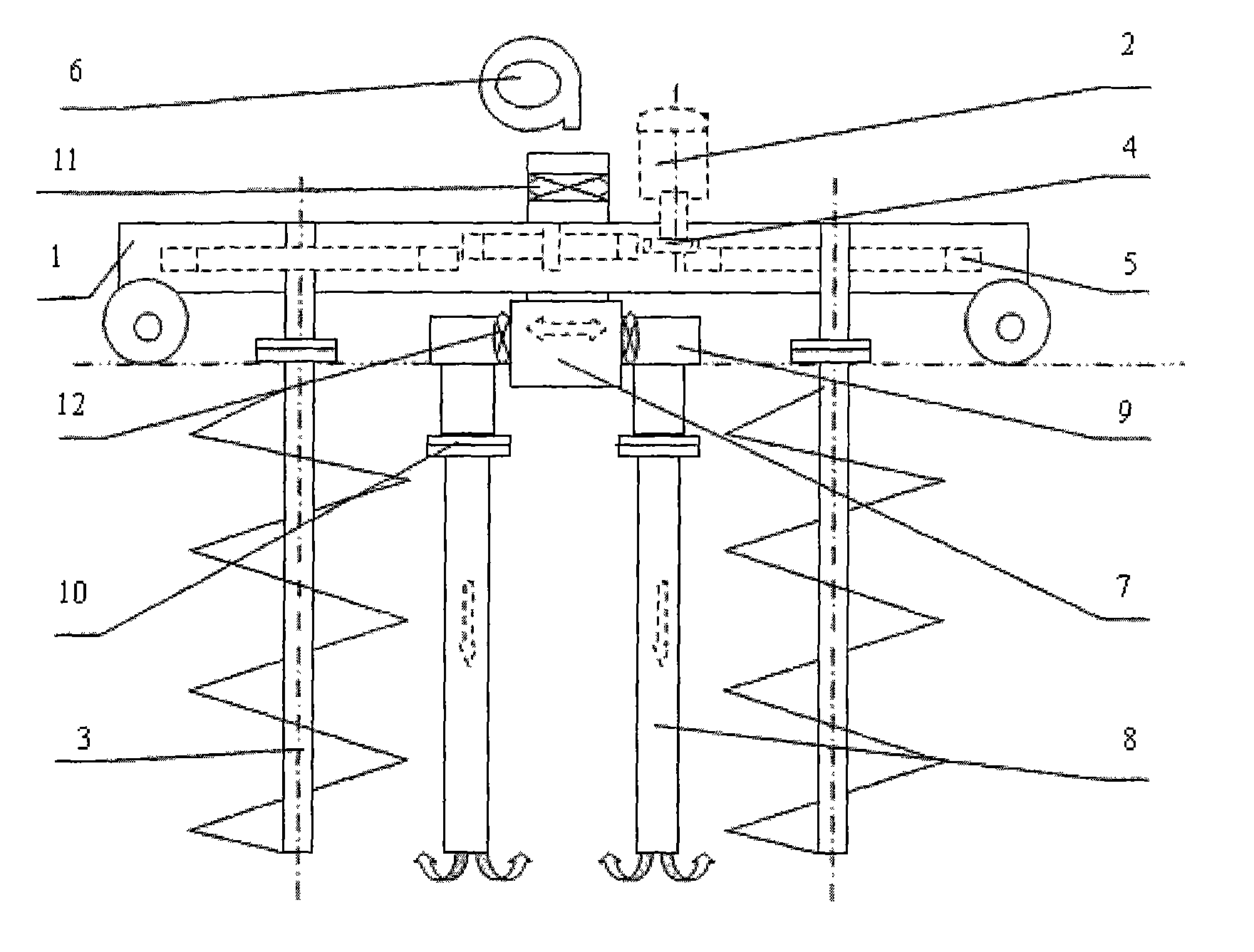

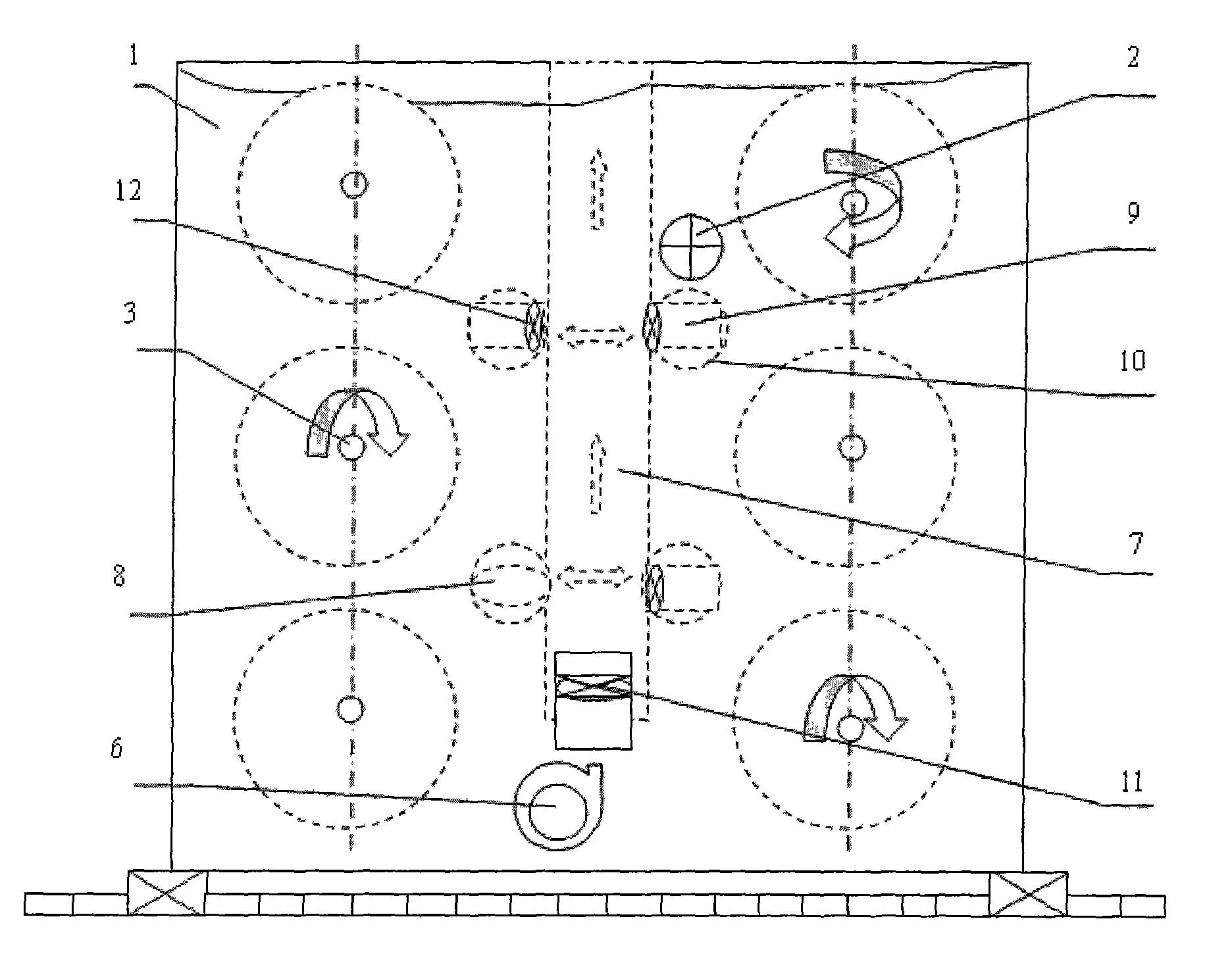

[0015] Such as figure 1 and figure 2 As shown, it includes a spiral turning device driving device 2 and a spiral turning device 3 arranged on a spiral turning machine frame 1, and transmission gears 4 and 5 are respectively installed on the driving device 2 and the turning device 3, and are passed through Gears 4 and 5 are connected.

[0016] The driving device 2 of the screw turning device of the present invention is a motor; the driving device 2 of the screw turning device is a diesel or gasoline engine; the turning device 3 is a screw auger or a screw cutter; The spiral auger 3 is at least one row; each row is at least two; the relative position between the spiral auger 3 is arranged regularly or the relative position is partially regular and partially irregularly arranged; it can also be completely Irregular arrangement and installation; the installation method of the screw auger 3 can be installed vertically or partially vertically, and partly with a certain inclinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com