Continuous casting machine for lead plate of lead-acid storage battery

A technology of lead-acid battery and continuous casting machine, applied in the direction of electrode carrier/collector, etc., can solve the problems of inconsistent thickness, poor uniformity of lead plate, and many burrs, and meet the requirements of performance and life, consistent mechanical strength, The effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

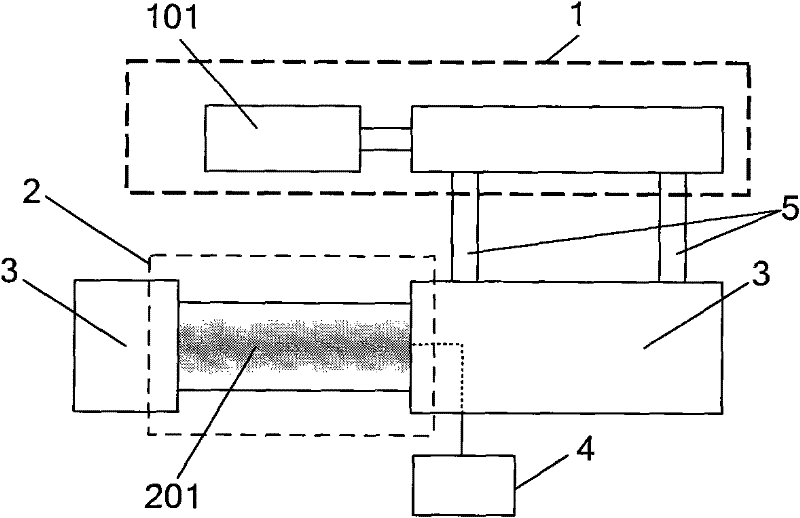

[0028] This embodiment provides a continuous caster for lead-acid batteries, which is a continuous casting and rolling grid lead manufacturing equipment, such as figure 1 As shown, the lead plate continuous casting machine includes:

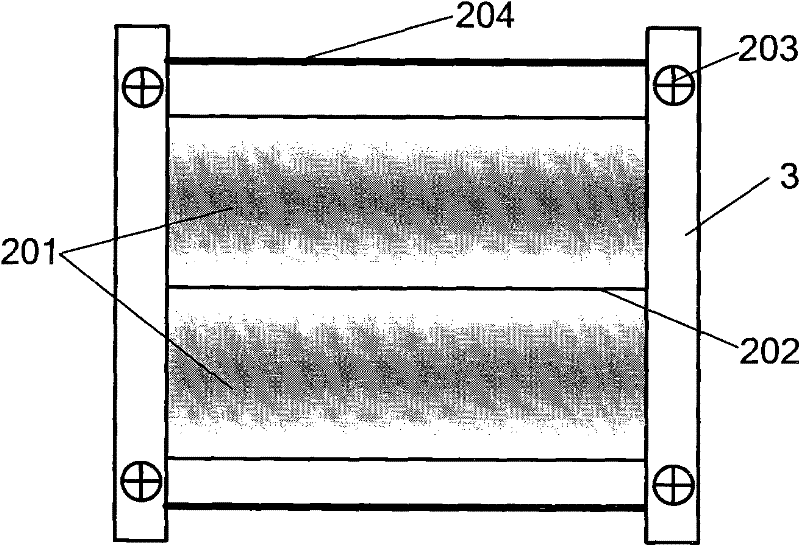

[0029] Lead liquid infusion device 1, roller pressing device 2, fixed support platform 3 and cooling device 4;

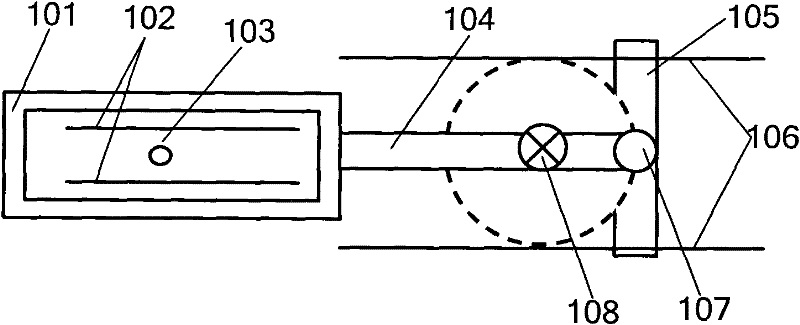

[0030] Among them, the lead liquid infusion device 1 includes: a moving lead spoon 101, a heating tube 102, a lead liquid output pipe 103, a rotating arm 104, a guide groove 105, a guide shaft 106, a movable bearing 107 and a driving device 108; wherein the guide groove 105 is movable It is arranged on the guide shaft 106, and the rotating arm 104 is arranged on the rotating shaft of the driving device 108. The driving device 108 can be a reducer or a motor. One end of the rotating arm 104 is arranged in the guide groove 105 through a movable bearing 107, and the other end of the rotating arm 104 is connected The mobile lead spoon 101, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com