Method for machining slender friction roller

A roller processing and roller technology is applied in the field of compensating the deflection and deformation of friction rollers due to its own weight, which can solve the problems of long processing cycle, complicated procedures and high manufacturing cost, and achieve the effect of simple processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for processing the slender roller for friction proposed by the present invention is described as follows in conjunction with the accompanying drawings and examples.

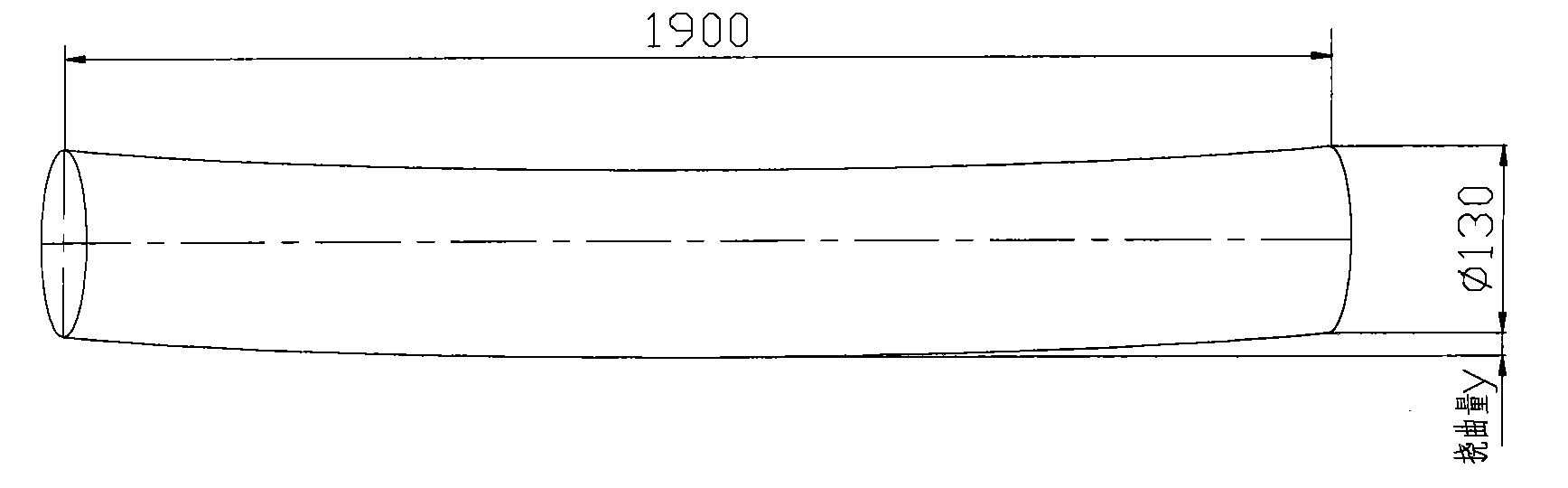

[0024] Realize the special-purpose precision machine tool of processing method of the present invention and comprise precision lathe head box, special-purpose lathe slide plate, precision lathe bed, precision lathe top; The rollers are clamped on the top ends similar to the friction and polishing machines, and the rollers are driven to rotate by the end face of the lathe spindle, and the turning tool cuts under the rollers to directly cut off the deflection of the rollers due to their own weight. Realize the direct compensation of the deflection deformation of the slender (such as φ100~φ200×1000~3000mm friction roller) roller.

[0025] like Figure 4 , Figure 5 As shown, the special precision machine tool used in the present embodiment includes a precision lathe head box 1, a tool rest 2, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com