Method of manufacturing adhesive-free laminate of aramid paper and polyphenylene sulfide film, and insulation material and insulation structure for rotating electric machinery

一种聚苯硫醚层、制造方法的技术,应用在绕组绝缘的形状/式样/结构、绝缘体、车辆部件等方向,能够解决柔软性损失等问题,达到容易环境保护的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

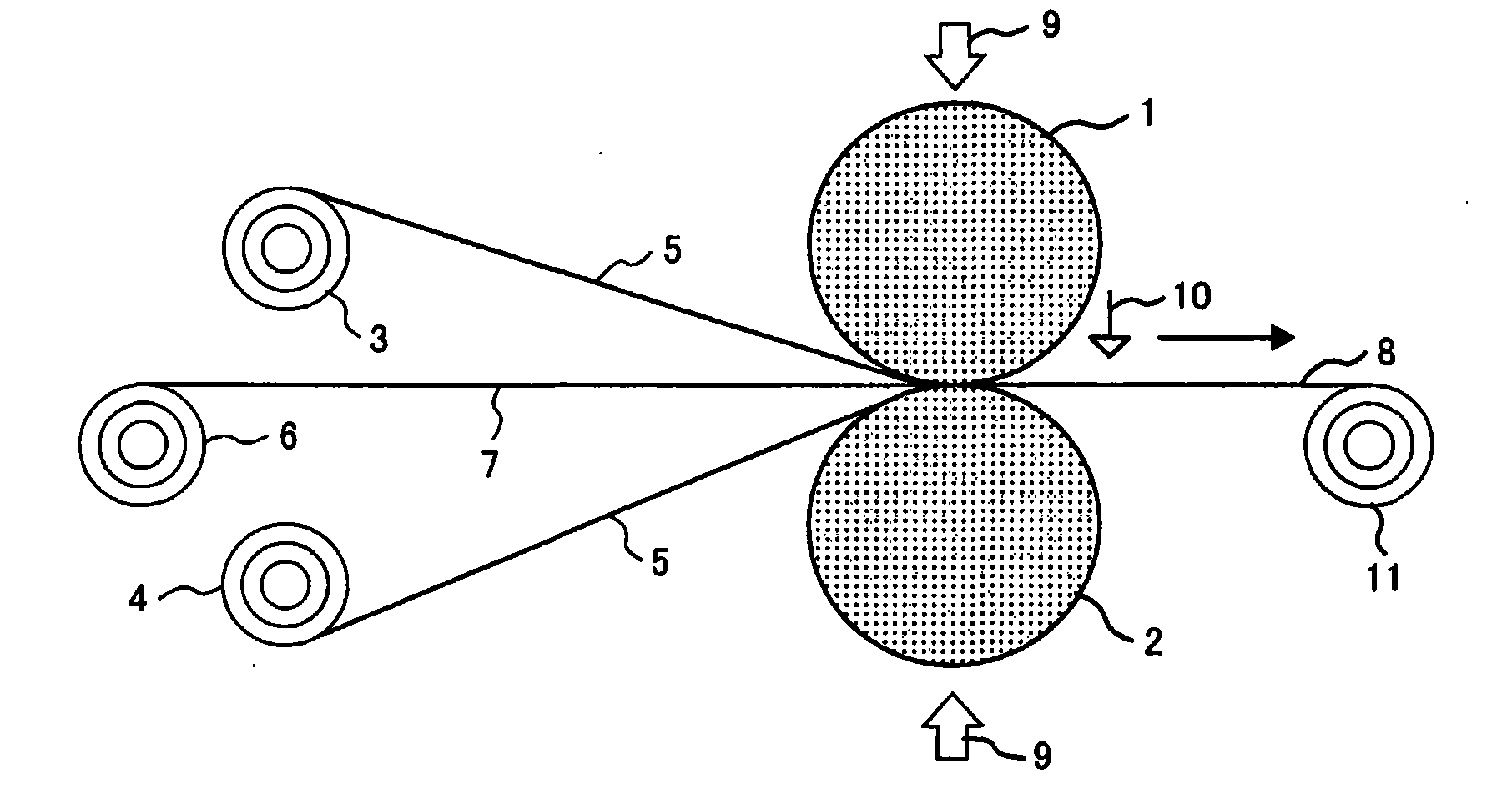

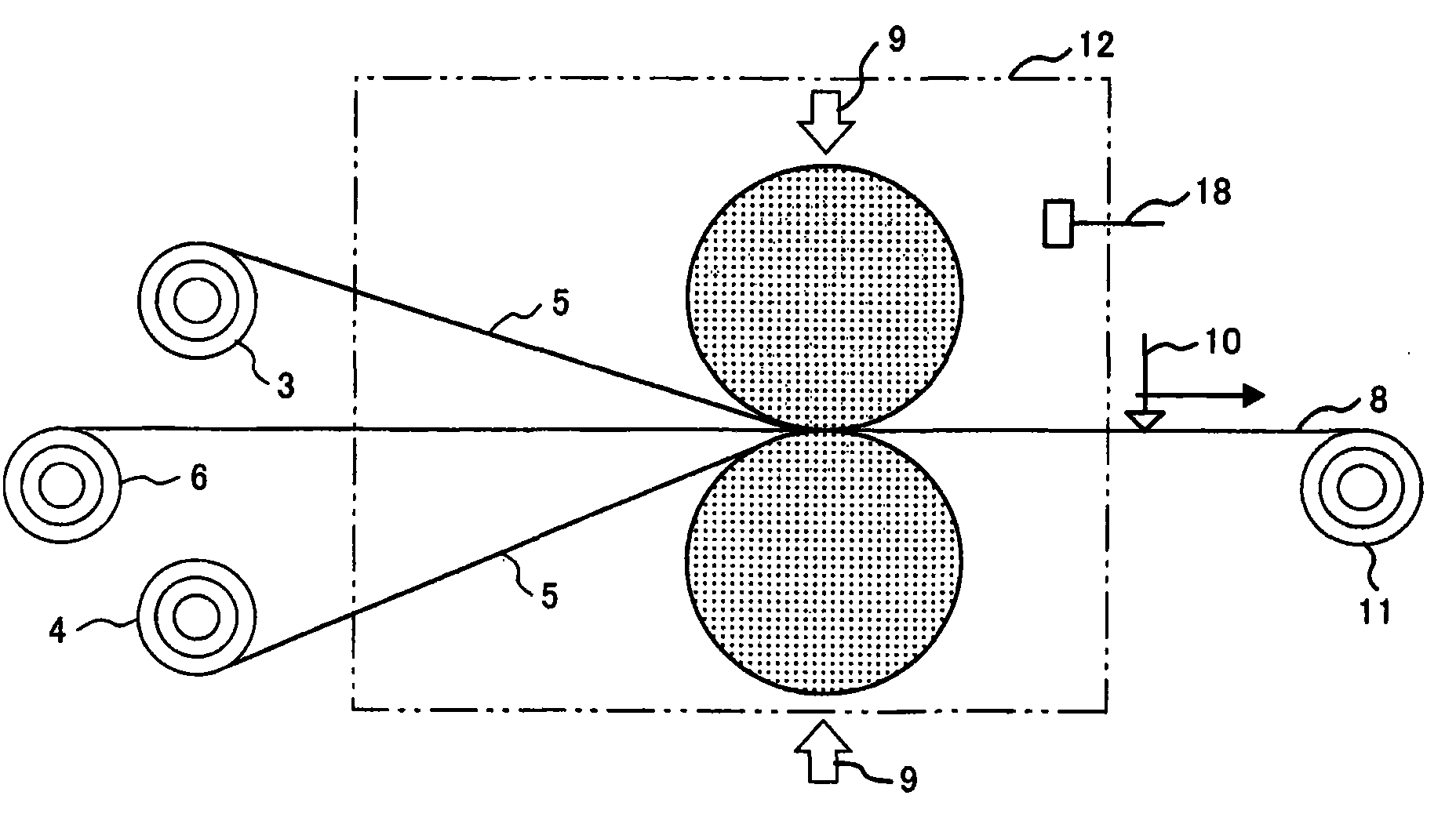

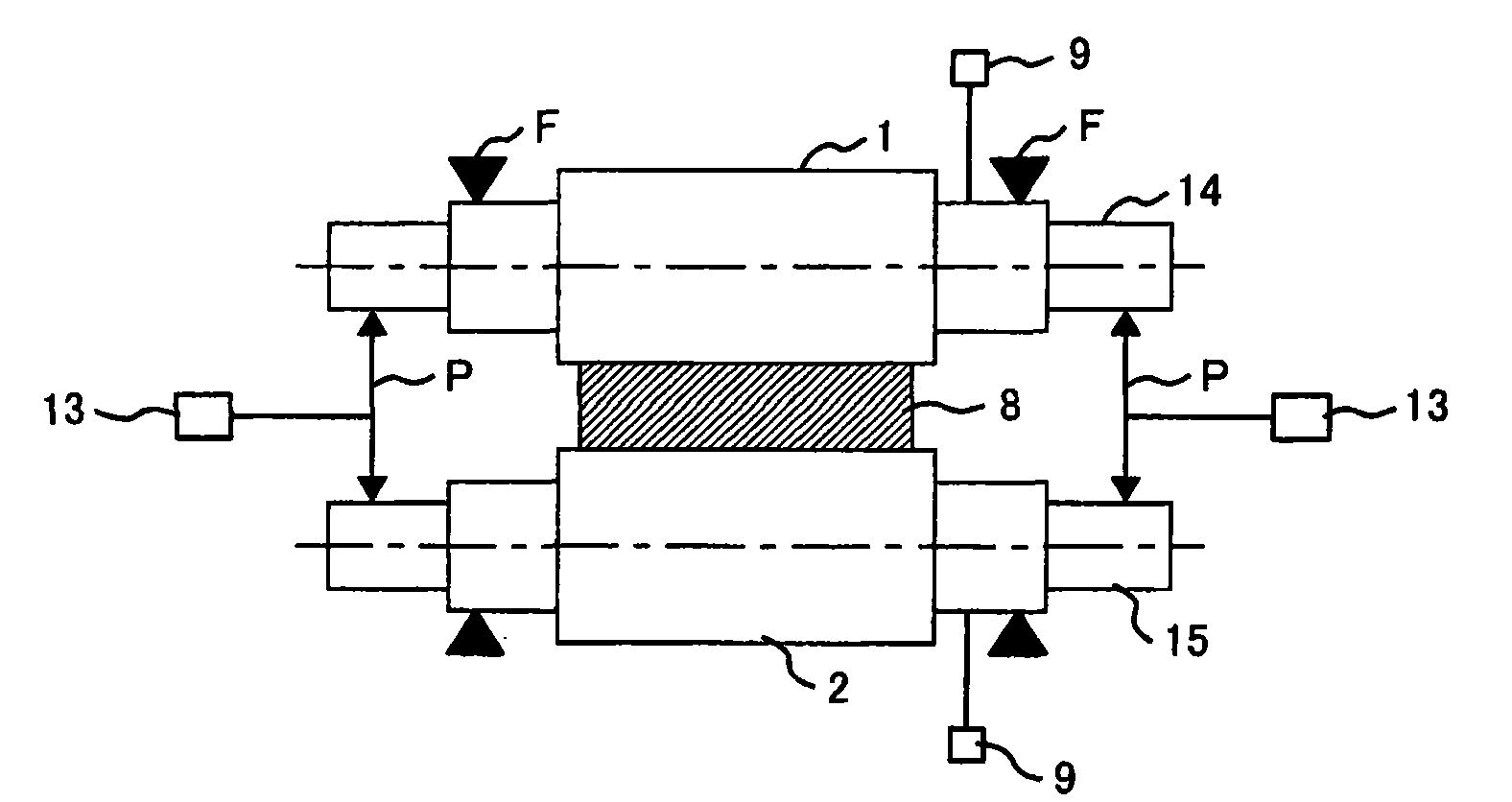

[0031] The aramid paper-PPS laminate of the invention of the present application is obtained by laminating the aramid paper and the PPS film after performing plasma surface treatment, and laminating these components at a temperature of 30°C to 50°C by a pair of pressure rollers. Manufactured by pressing a pressure of 500kgf / cm or more or at a temperature of 50°C to 100°C and a linear pressure of 200kgf / cm or more by a pair of pressure rollers.

[0032] Aramid paper, specifically the m-aramid paper known under the registered trademark of DuPont's ノ-メツクス, is made of aramid fiber and aramid pulp made of polyisophthalamide-containing It is composed of m-phenylenediamide (meta-aramid fiber) or its main component copolymer or mixed copolymer. There are no particular limitations on the component or the amount of the component to be copolymerized or mixed with the meta-aramid as long as the properties of the meta-aramid are not lost. For example, the components thereof include tereph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com