Combined processing technique of garbage percolates

A landfill leachate and treatment process technology, which is applied in the field of high-concentration organic wastewater treatment, can solve the problems of difficult treatment of deamination tail gas, small gas-liquid contact area, high investment and operation cost, and achieve good supplementary synergistic effect and reasonable operation cost , Reduce the effect of civil construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

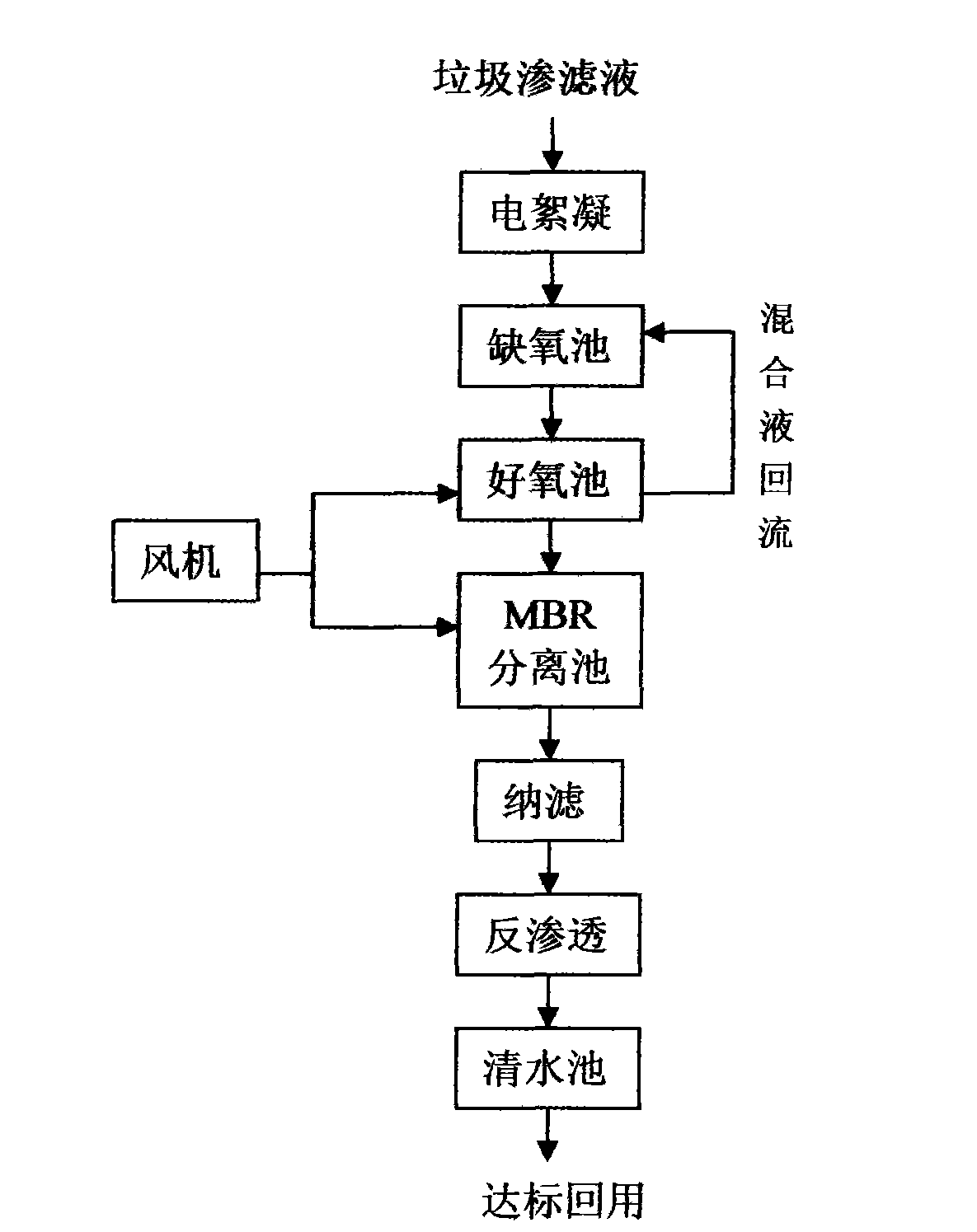

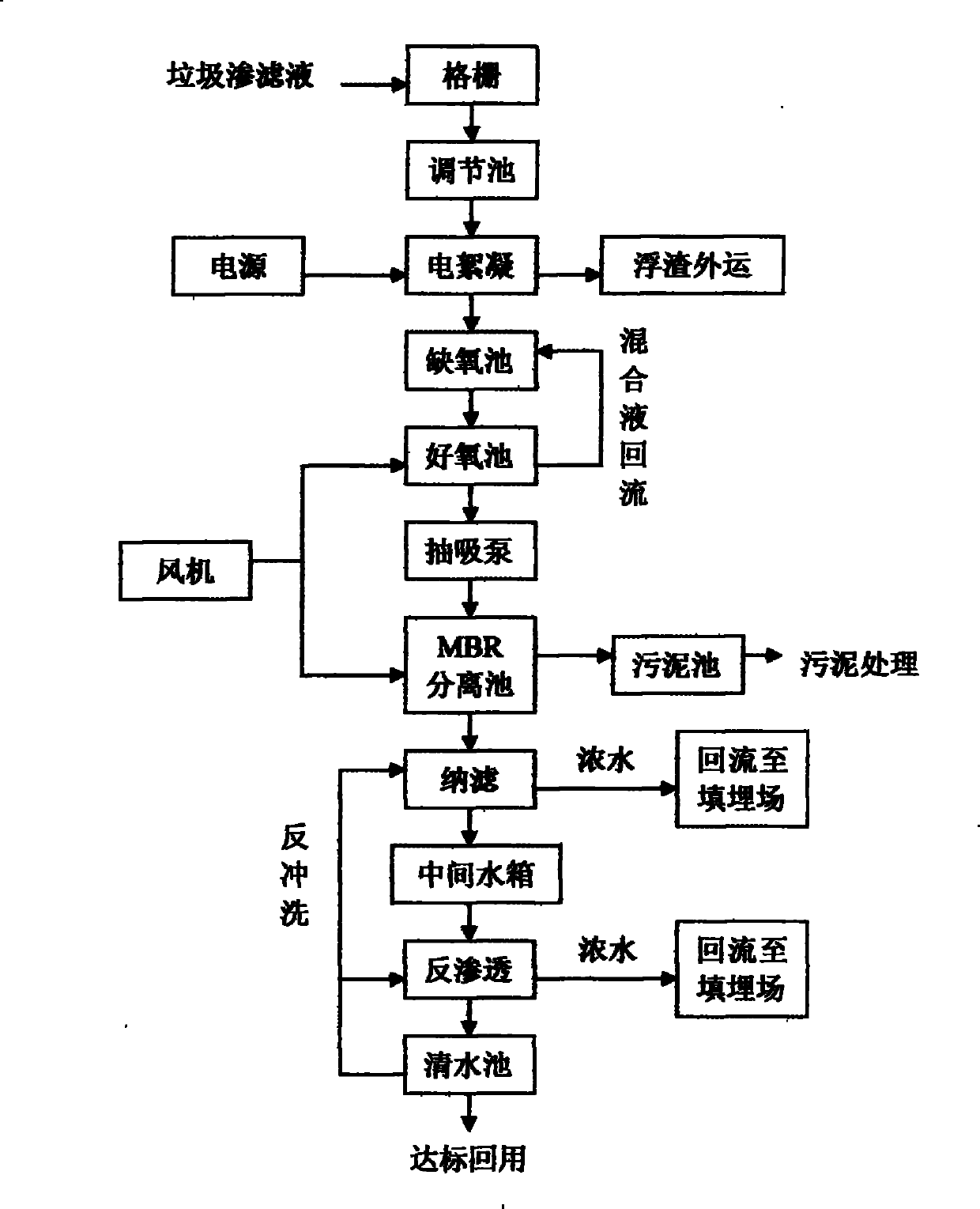

[0014] Attached below figure 2 , process method of the present invention is described in detail:

[0015] 1. The landfill leachate first passes through the grid to trap debris, and then enters the regulating tank. Since the water quality and water volume of landfill leachate are greatly affected by seasons and time, the function of the regulating tank is to concentrate a large amount of landfill leachate so that it can be lifted to the next treatment unit through the sewage pump, and at the same time, it can be uniform in water quality. And, reduce the load impact on the subsequent processing system.

[0016] 2. Lift the effluent in step 1 to the electrocoagulation device, the rising speed of the water flow is 12L / h; the reaction time is 2h, and the current density is 100mA / cm 2 Under certain conditions, more than 80% of pollutants can be removed.

[0017] 3. After the water is discharged from the electrocoagulation device, it enters the anoxic pool, and the residence time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com