Directly operated and pilot operated hybrid multi-connection solenoid valve

A pilot-operated, direct-acting technology, applied in the field of solenoid valves, can solve the problems of blockage of the micro-flow controller, easy water leakage of the main valve seat, etc., and achieve the effect of precise flow control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

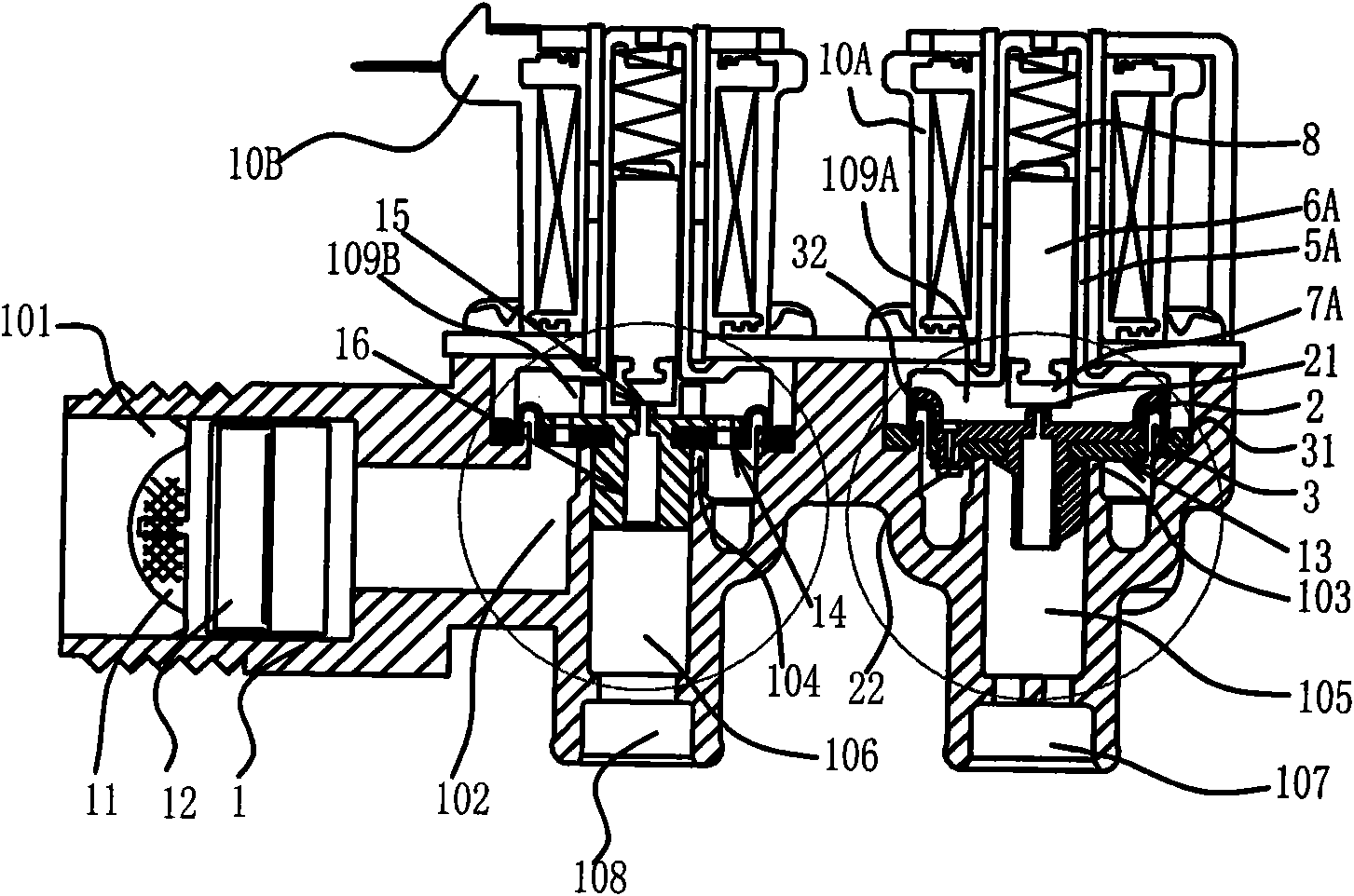

[0043] The direct-acting and pilot-operated mixed multi-connection solenoid valves of this embodiment, see figure 1 , figure 2 , Figure 7 , Figure 8 , Figure 10a , Figure 10b , Figure 10c , Figure 12a , Figure 12b , Figure 14a , including a valve body 1, the valve body is provided with an inflow port 101, a water supply chamber 102, and at least one pilot valve. The pilot valve has a main valve seat A103, an outflow chamber A105 corresponding to the main valve seat A, and an outflow port A107. The main valve seat A103 is equipped with a valve A13 composed of diaphragm A2 and diaphragm A3. Diaphragm A2 is embedded in the convex body of the central hole of diaphragm A3, and a guide hole 21 is opened on the upper part of the convex body. Diaphragm A2 is embedded in the convex body of a peripheral hole 33 of diaphragm A3. A side hole 22 is opened on the body, a conduit A5A is provided in the back pressure chamber A109A of the valve body, and a piston A6A is arrang...

Embodiment 2

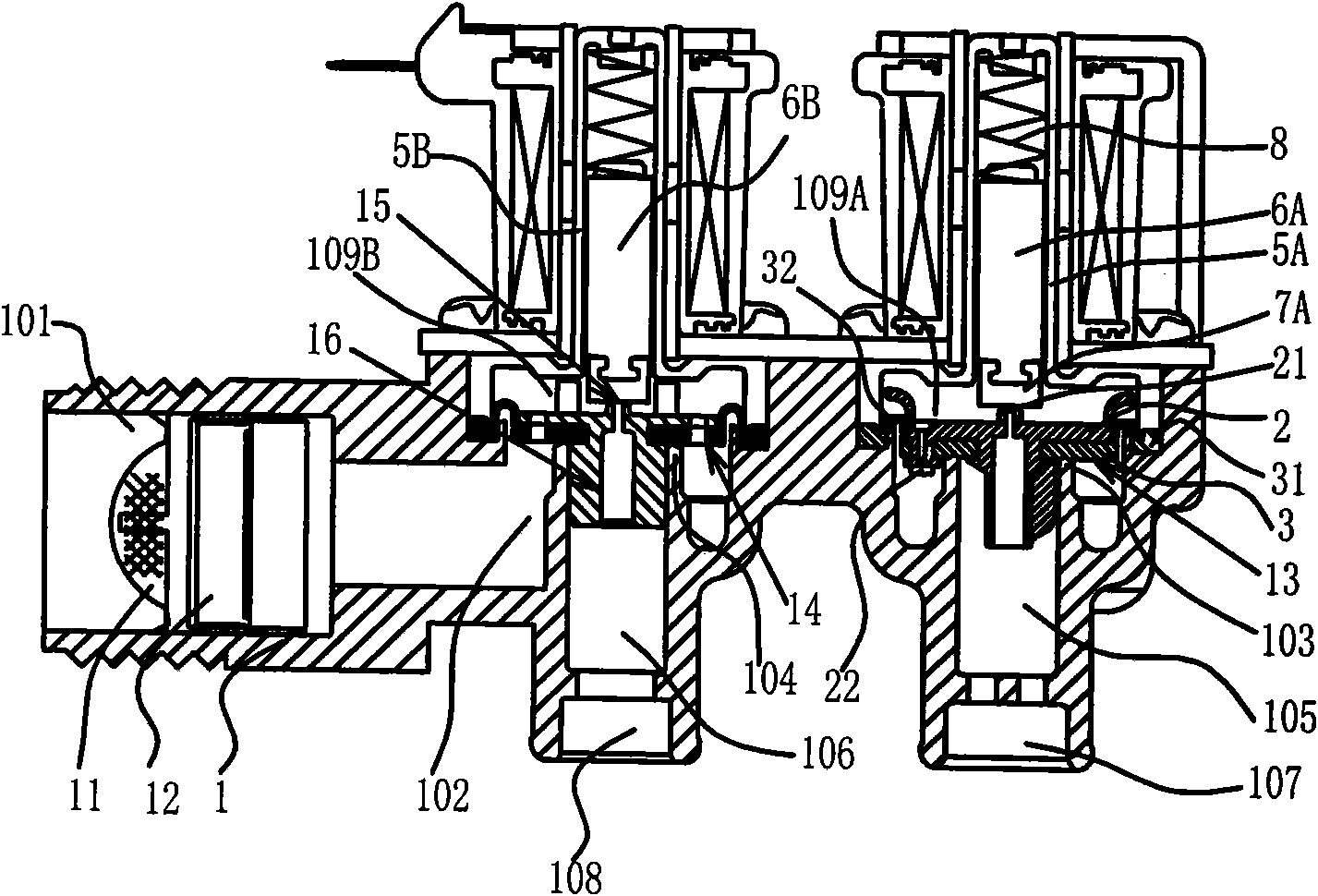

[0051] The direct-acting and pilot-operated mixed multi-connection solenoid valves of this embodiment, see image 3 , Figure 11, Figure 12c , Figure 13a , Figure 13b The difference between this embodiment and the first embodiment is that: the diaphragm plate B41 and the protruding structure 412 may be an integral part or two separate parts. The protruding structure 412 on the diaphragm B41 is in contact with the lower end of the conduit B5B so that the diaphragm B42 is located on the main valve seat B104; 414 is located on the main valve seat B104.

[0052] Compared with the first embodiment, the manufacturing process of the diaphragm plate B41 is different due to the different structure of the diaphragm plate B41. In practice, the user can make a choice according to the needs.

Embodiment 3

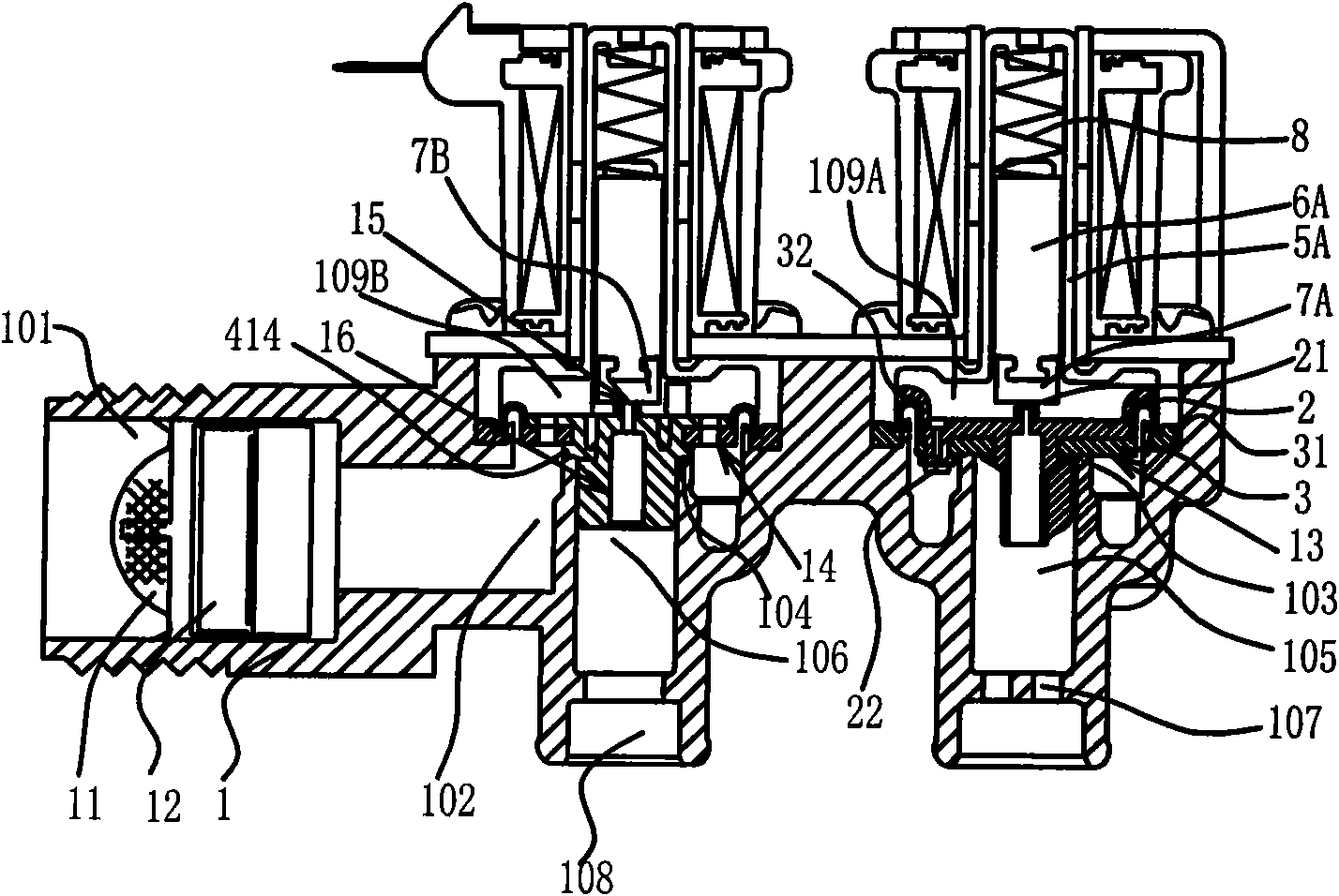

[0054] The direct-acting and pilot-operated mixed multi-connection solenoid valves of this embodiment, see Figure 4 , Figure 9 , Figure 12a , Figure 14a , Figure 16 , based on Embodiment 1, this direct-acting and pilot-operated hybrid multi-connection solenoid valve is provided with a small flow control unit 9 composed of a flow ring 91 and a flow control plate 92 at the lower part of the outflow chamber B106 of the main valve seat B104. The flow control water flows into the back pressure chamber B109B through the water supply chamber 102, the special-shaped hole 413 outside the diaphragm B41, the fine-mesh filter 43, and the special-shaped hole 422 of the diaphragm B, and is always in a communication state. Contact, the assembly of diaphragm B41 and diaphragm B42 is located on the main valve seat B104, so that the valve B14 is always closed. When the electromagnetic coil B10B is energized, the piston B6B is attracted to drive the piston cap B7B to open the central gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com