Method for manufacturing LED indicator light

A technology of LED indicator light and manufacturing method, which is applied to parts of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., can solve problems such as cumbersome production processes and hidden dangers in product quality, and achieve reduction of manufacturing processes and improvement Product reliability and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

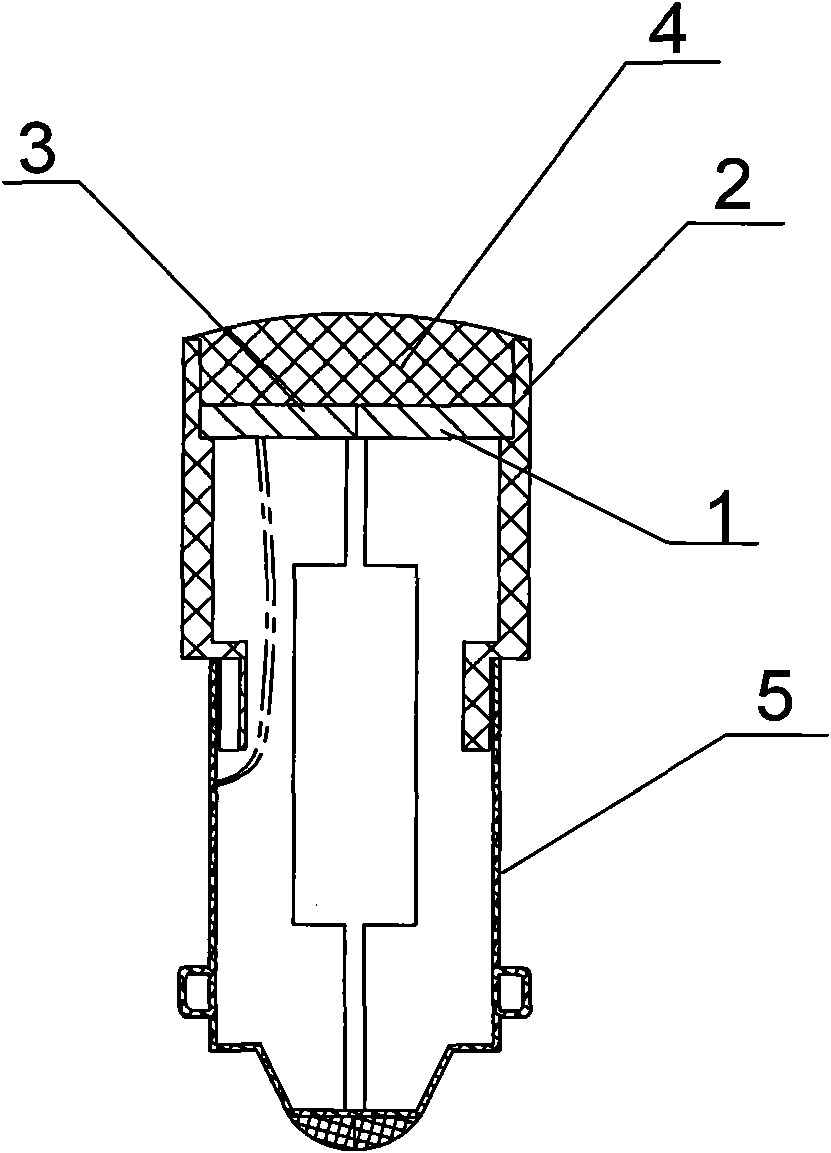

[0015] Such as figure 1 Shown, a kind of manufacturing method of LED indicator light, this method comprises the following steps:

[0016] a. Add silicon dioxide powder in the epoxy resin, the ratio is 6%, and stir evenly to increase the viscosity of the epoxy resin;

[0017] b. Put the PCB circuit board 1 with LED into the reflective cavity 3 formed by the plastic shell 2 and place it flat;

[0018] c. Use a glue filling machine to inject the prepared epoxy resin from the front of the reflection cavity 3, cover the PCB circuit board 1 with LEDs, and form an arc-shaped epoxy resin layer 4 on the front of the reflection cavity; because it is specially prepared epoxy resin glue , high viscosity, the glue will not flow out along the PCB gap to the other side of the circuit board with electronic components, all electronic components are sealed ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com