Mechanism and method thereof for detecting clamping force of test piece in flat thermal conductivity coefficient measuring instrument

A technology of thermal conductivity and detection mechanism, applied in the direction of thermal conductivity of materials, measuring force, instruments, etc., can solve the problems of large volume, complex implementation, and no pressure measurement function, and achieve a small mechanism, simple implementation, and improved repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The test piece clamping force detection mechanism and detection method of the plate thermal conductivity measuring instrument of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

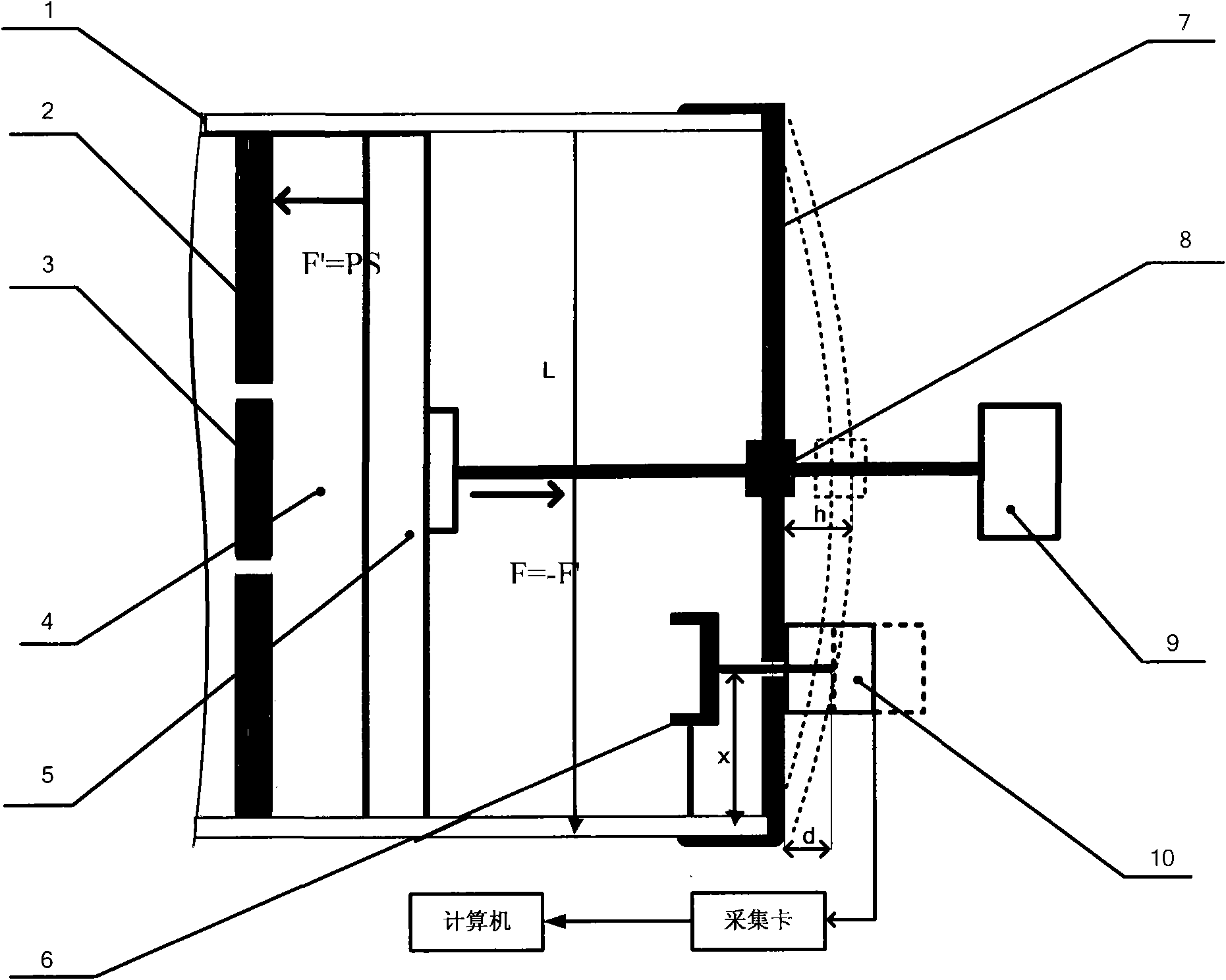

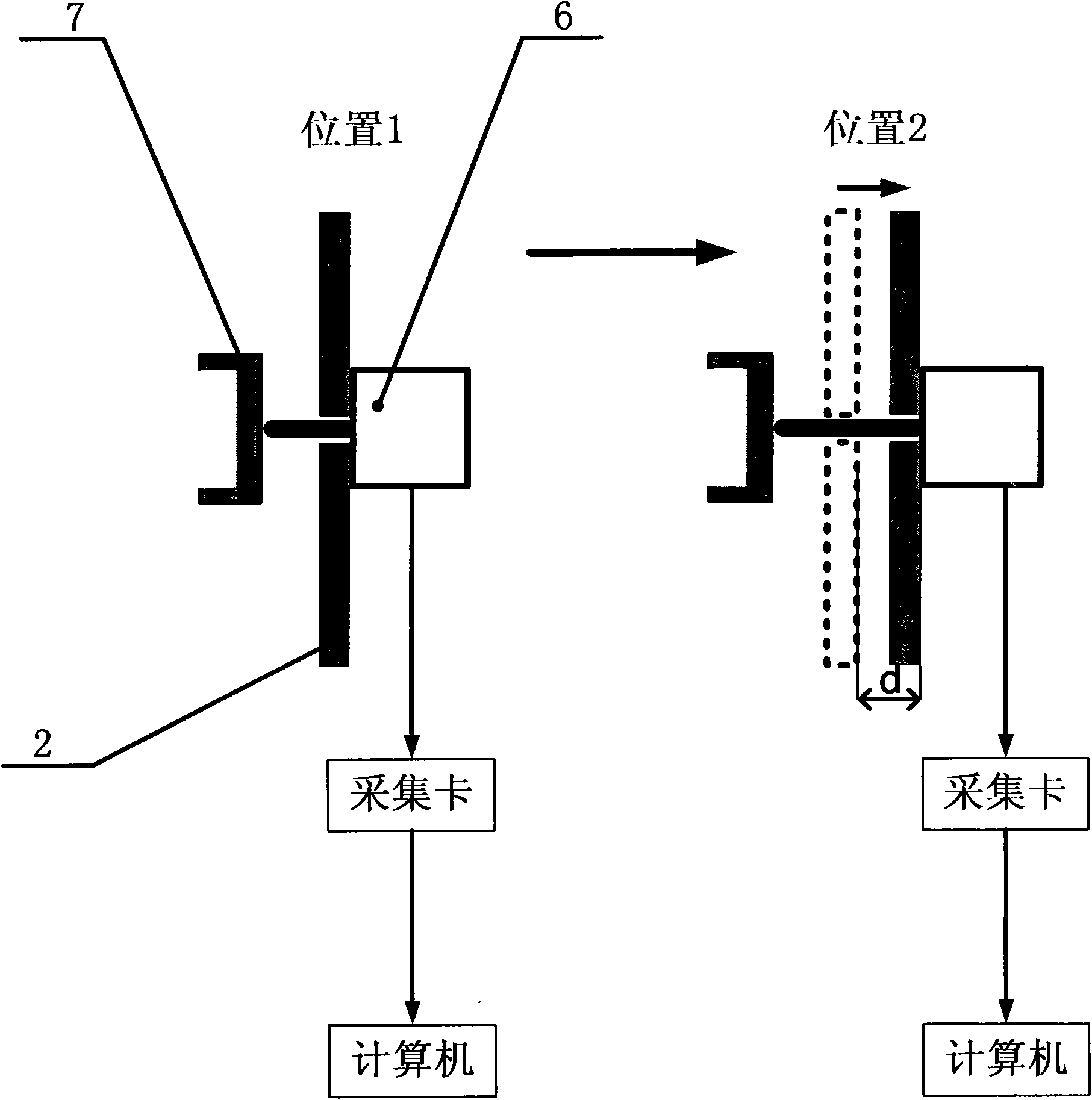

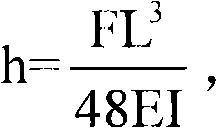

[0014] The test piece clamping force detection mechanism of the flat plate thermal conductivity measuring instrument of the present invention includes a control part, a detection part with an instrument main barrel 1, an instrument barrel cover 7, a guard plate 2, a main board 3, a cold plate 5 and an instrument barrel cover. The contacting cold plate propulsion part is provided with a clamping force measuring mechanism 10 on the base plate of the instrument barrel cover 7, and the probe at the bottom of the clamping force measuring mechanism 10 is arranged on the instrument barrel cover 7 through its own resilience. The fixed beam 6 on the inner side is connected, the clamping force measuring mechanism 10 is electrically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com