Zoom liquid crystal lens

A liquid crystal lens and liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high operating voltage, increased thickness and cost, and insufficient adjustable focal length range, and achieve the effect of reducing thickness and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

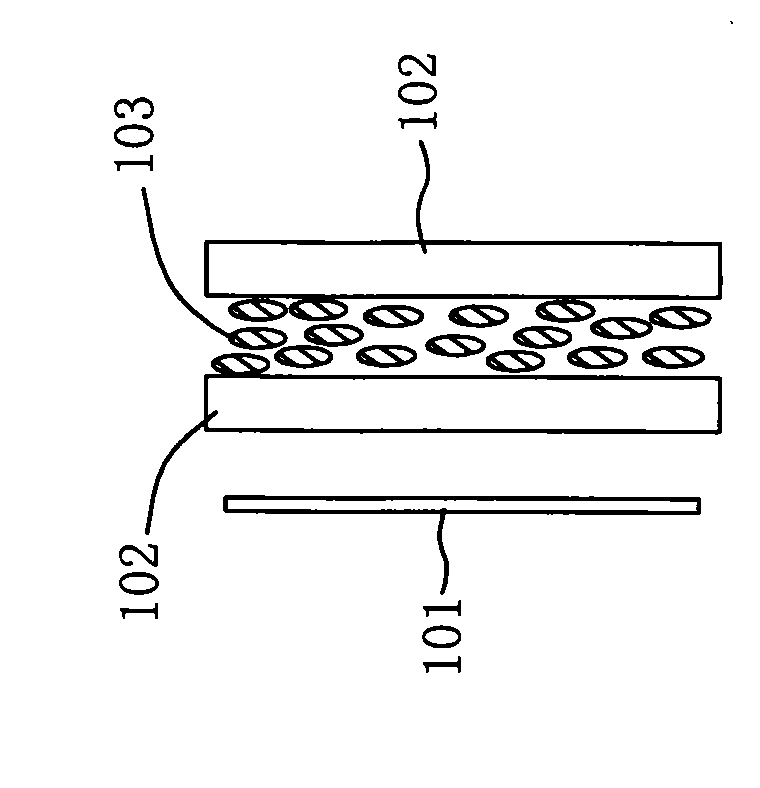

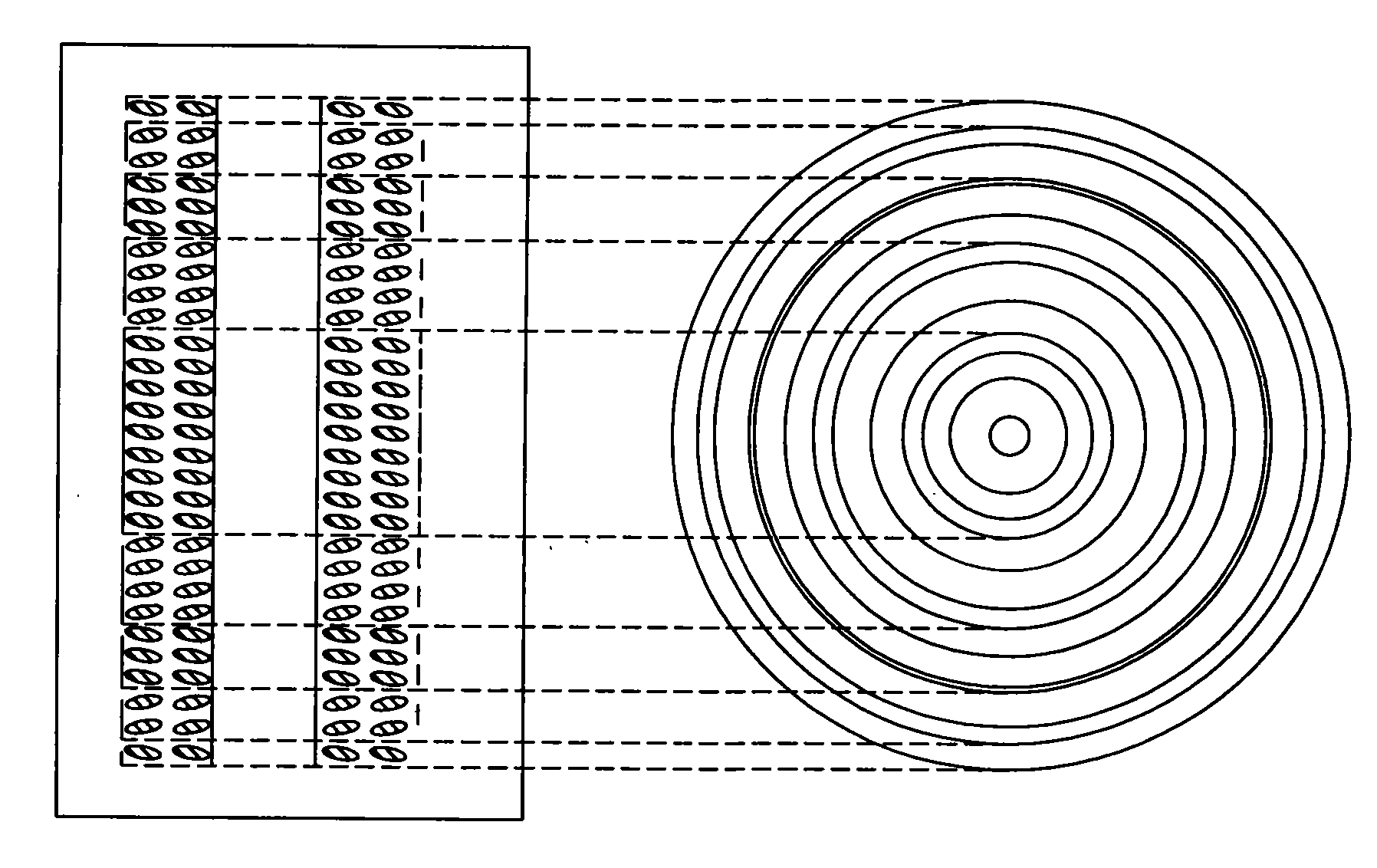

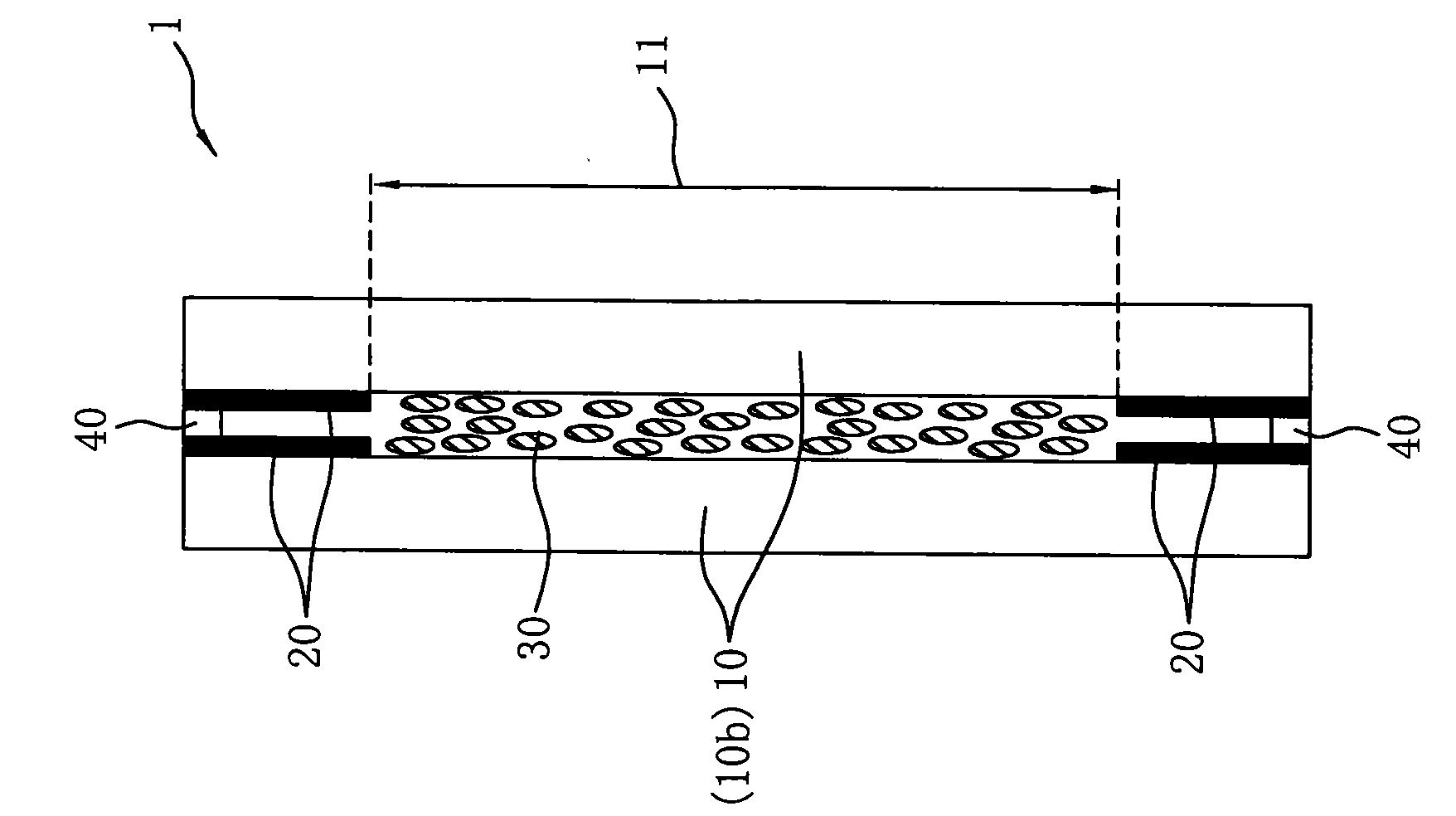

[0036] refer to figure 2 , 3 As shown, it is the basic structure of an embodiment of a zoom liquid crystal lens composed of a single-layer liquid crystal lens unit in the present invention. The single-layer zoom liquid crystal lens 1 of this embodiment, counting from the side of the object, includes: one surface is provided with a surface alignment The glass substrate 10 of the electrode 20 (hereinafter referred to as the single-sided electrode glass substrate 10b), the spacer (spacer) 40, and the liquid crystal layer 30 and the single-sided electrode glass filled in the chamber formed by the single-sided electrode glass substrate 10b and the spacer 40 Substrate 10b; wherein, the spacer 40 can be a ring-shaped sheet or several stacked ones; wherein, a surface alignment electrode 20 is attached to the surface of the glass substrate 10, and the surface alignment electrode 20 is formed on the glass substrate 10 A metal film is coated, such as aluminum, silver, or gold, and the ...

no. 2 example

[0053] refer to Figure 9As shown, it is the basic structure of an embodiment of the double-layer zoom liquid crystal lens composed of double-layer liquid crystal lens units of the present invention. The double-layer zoom liquid crystal lens 2 of the present embodiment, counting from the object side, includes: a single-sided electrode glass substrate 10b, a spacer 40 and a first layer of liquid crystal layer 30, a double-sided electrode glass substrate 10a, a spacer 40 and a second layer The liquid crystal layer 30 and the single-sided electrode glass substrate 10b; wherein, between the single-sided electrode glass substrate 10b and the double-sided electrode glass substrate 10a, the thicknesses of the two liquid crystal layers 30 are respectively defined by the spacer 40 . When the incident light refracts for the first time through the first layer of liquid crystal layer 30 of the zoom liquid crystal lens 2, and then enters the second layer of liquid crystal layer 30 of the l...

no. 3 example

[0061] refer to Figure 10 As shown, it is the basic structure of the embodiment of the three-layer zoom liquid crystal lens 3 composed of three-layer liquid crystal lens units in the present invention. The three-layer zoom liquid crystal lens 3 of the present embodiment, counting from the side of the object, includes: a single-sided electrode glass substrate 10b, a spacer 40 and a first layer of liquid crystal layer 30, a double-sided electrode glass substrate 10a, a spacer 40 and a second layer Liquid crystal layer 30, double-sided electrode glass substrate 10a, spacer 40, third layer liquid crystal layer 30, and single-sided electrode glass substrate 10b; between the single-sided electrode glass substrate 10b and the double-sided electrode glass substrate 10a, with The spacers 40 respectively define the thicknesses of the three liquid crystal layers 30 . When the incident light passes through the first layer of liquid crystal layer 30 of the three-layer zoom liquid crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com