Touch-control display panel and display device

A touch display panel and display device technology, applied in the direction of identification devices, static indicators, instruments, etc., can solve the problems of low screen printing process precision, reduction, and limited design space of display devices, etc., to achieve the expansion of display screen size, The effect of reducing resistance value and line width, and high process precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] touch display panel

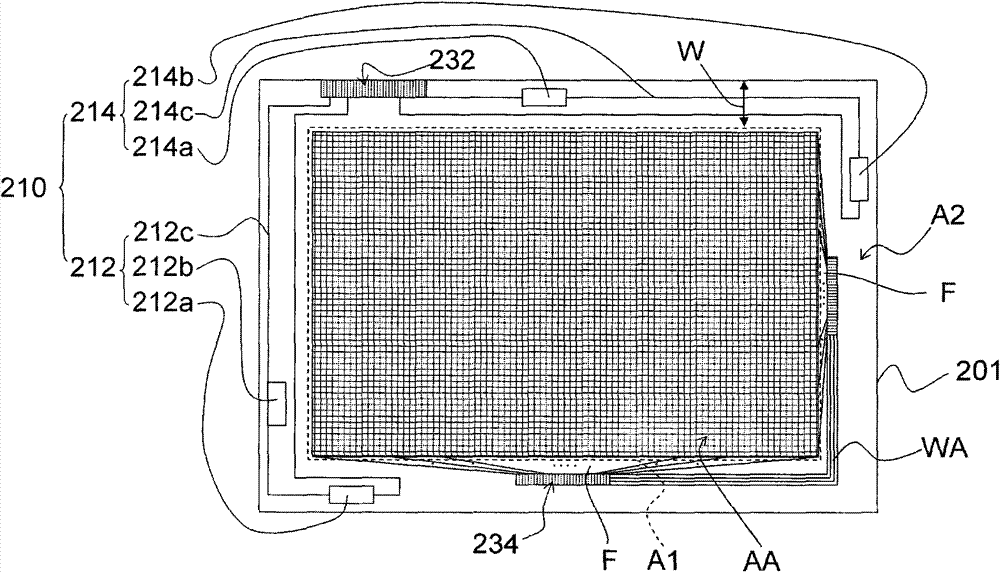

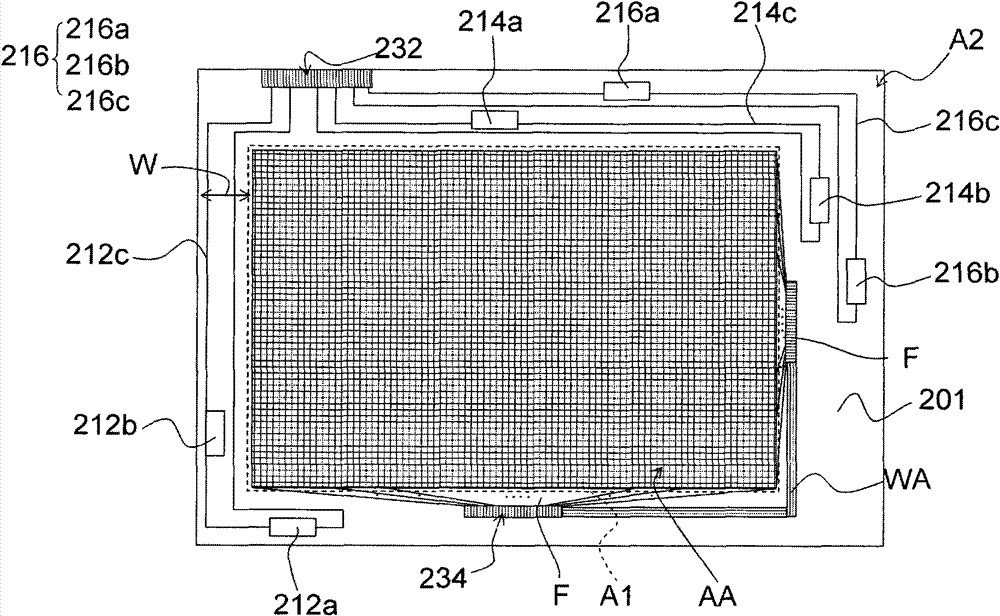

[0051] Figure 2A It is a schematic top view of a first substrate and components disposed on the first substrate in a touch display panel according to an embodiment of the present invention. Figure 3A It is a schematic side view of a touch display panel according to an embodiment of the present invention.

[0052] Please refer to Figure 2A , the touch component 210 is disposed on the first substrate 201 . The first substrate 201 has a display area A1 and a non-display area A2, and the non-display area A2 is located outside the display area A1. The touch component 210 is directly disposed on the first substrate 201 and located in the non-display area A2 , wherein the touch component 210 is composed of two sets of receiving components 212 , 214 .

[0053] Specifically, the receiving component 212 is composed of a piezoelectric component 212a, a piezoelectric component 212b and a transmission wire 212c, and the transmission wire 212c connects the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com