Process for wetly crushing and processing thick carbon black after pyrolysis of waste rubber

A technology of wet crushing and waste rubber, which is applied to the removal of solid waste and grain treatment, etc., to achieve the effect of convenient operation, no leakage, and elimination of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

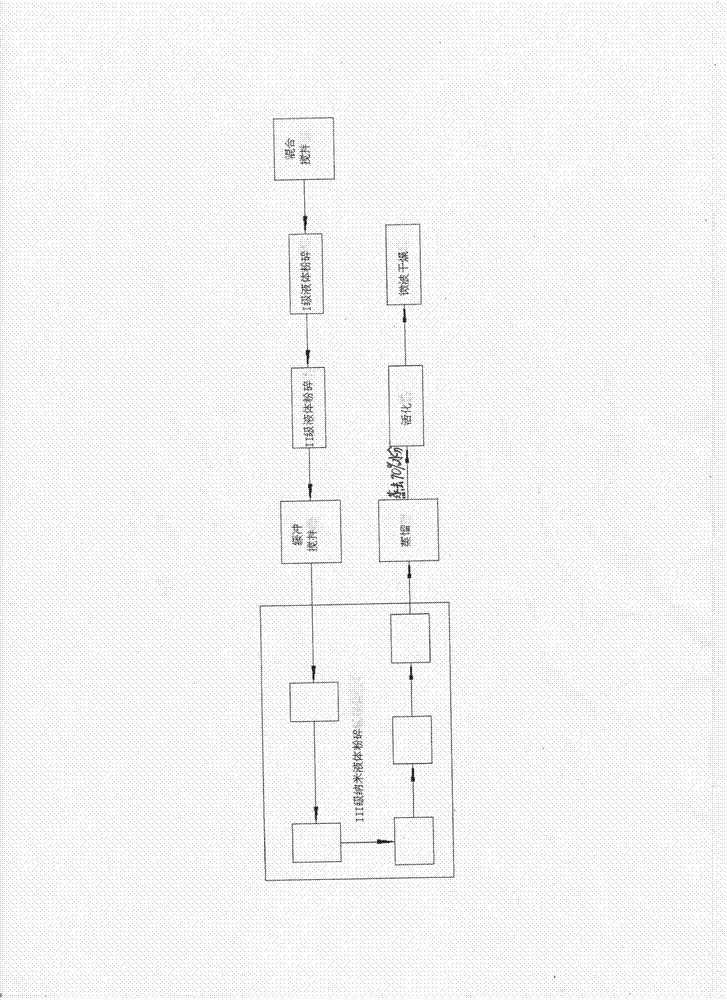

[0007] The equipment used in the process of the present invention has a mixing tank, a Class I liquid pulverizer, a Class II liquid pulverizer, a buffer stirring tank, a Class III liquid nano fine pulverizer system, a still, an activation machine, a microwave dryer, and a Class I liquid pulverizer The liquid inlet of the mixer is connected with the liquid outlet of the mixing tank, the liquid inlet of the II-level liquid pulverizer is connected with the liquid outlet of the I-level liquid pulverizer, and the liquid inlet of the buffer mixing tank is connected with the outlet of the II-level liquid pulverizer. The liquid ports are connected, and five liquid nano fine pulverizers are connected in series to form a class III liquid nano fine pulverization system. The liquid inlet is connected to the liquid outlet of the buffer stirring tank, and the liquid outlet of the III liquid nano fine pulverization system is connected The still, the liquid outlet of the still is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com