Processing control method of industrial robot based on G code conversion method

A technology of industrial robots and control methods, applied in the direction of digital control, electrical program control, etc., can solve problems such as poor practicability and achieve good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

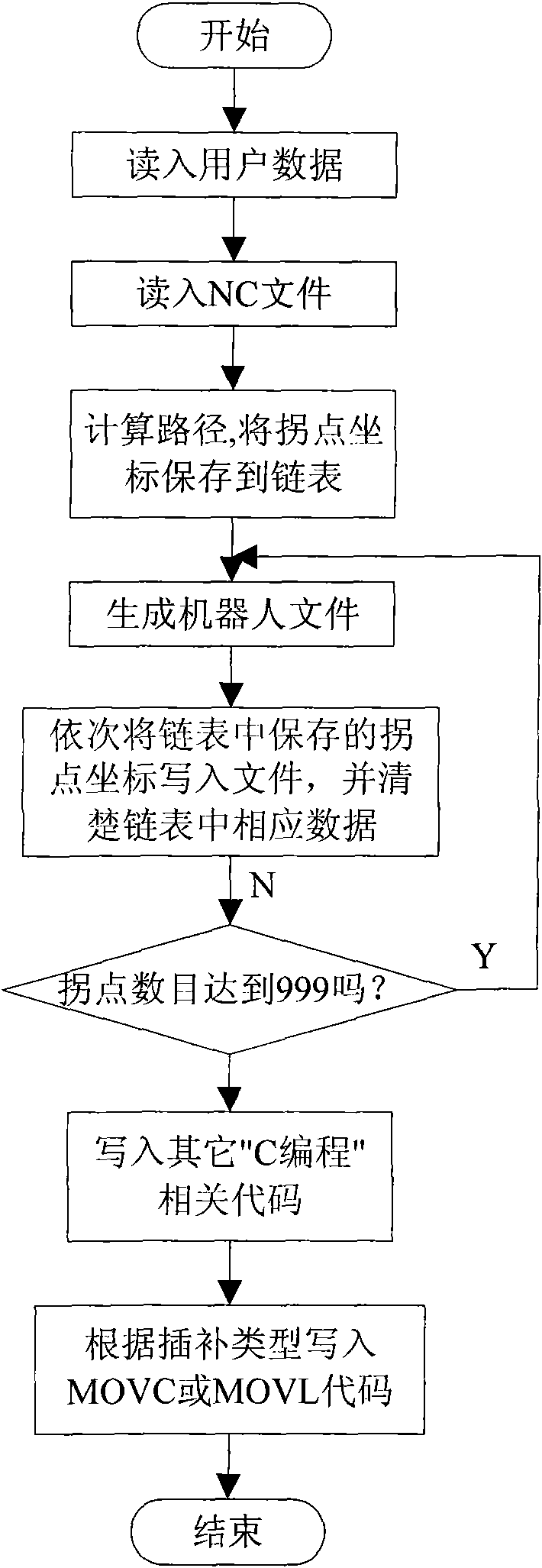

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

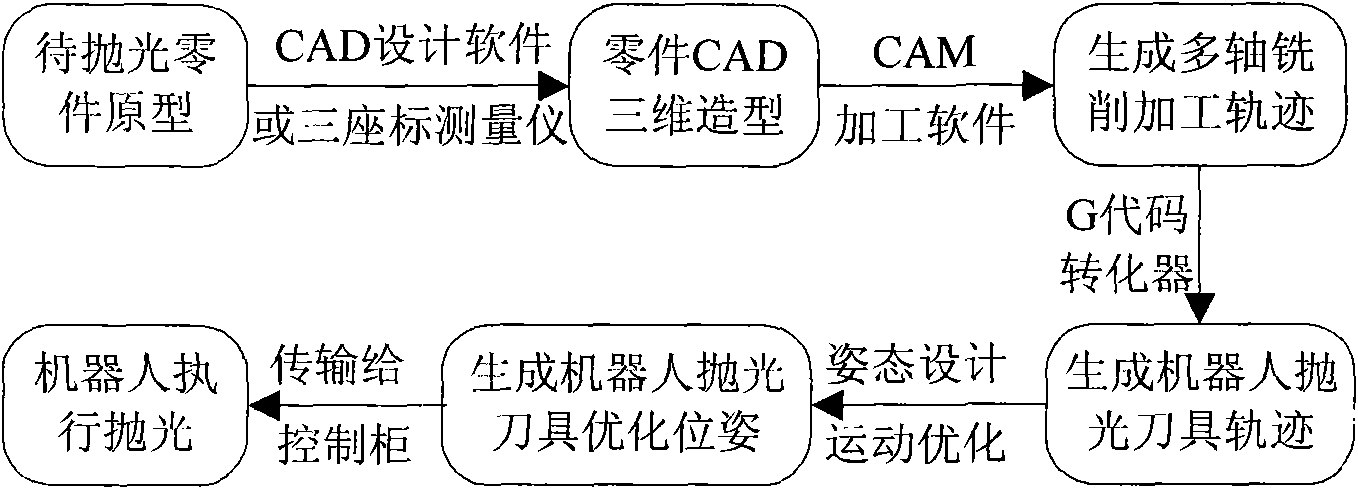

[0025] refer to figure 1 and figure 2 , an industrial robot processing control method based on the G code conversion method, providing a computer software and method, which can convert NC files into work files that can be recognized and executed by Motoman robots, and provide customization means to make G based on this method Transcoders are extensible.

[0026] The control method of the present embodiment comprises the following steps:

[0027] The first step is to obtain user-customized data, that is, input initial conditions and robot information in the graphical user interface, such as the robot’s interpolation mode, interpolation speed, path planning process characteristics, and the initial pose of the robot’s execution end.

[0028] The second step is to import the NC file and calculate the coordinates of the inflection point, that is, read the coordinates of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com