Braking vacuum servo force system and braking vacuum servo force control method

A control method and a technology of vacuum boosting, which are applied in the field of brake vacuum booster system and brake vacuum booster control, can solve the problem of brake booster control, cannot guarantee the safety of drivers to the greatest extent, and cannot fully realize the reliability and effectiveness of the brake vacuum booster system and other issues to achieve the effect of increasing reliability and effectiveness and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

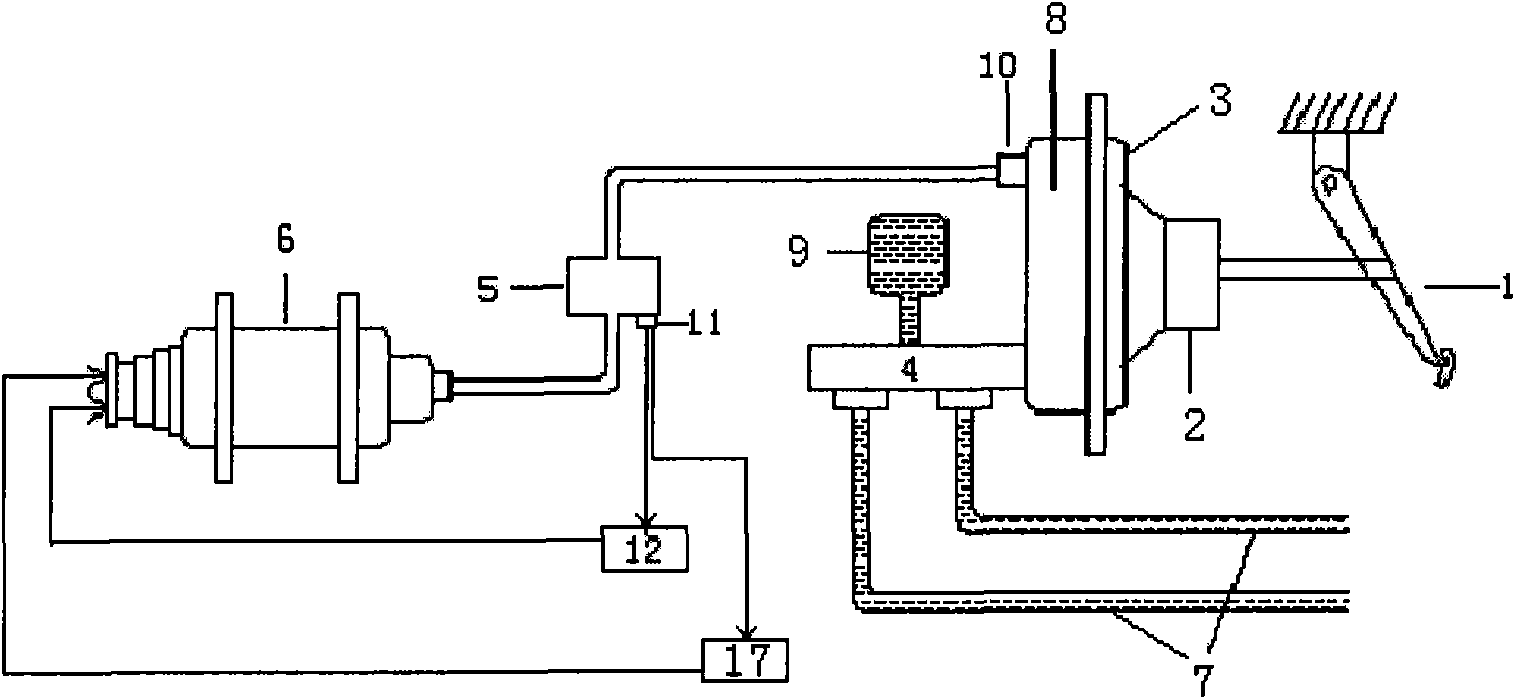

[0012] The brake vacuum booster system and the control method of the brake vacuum booster system provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

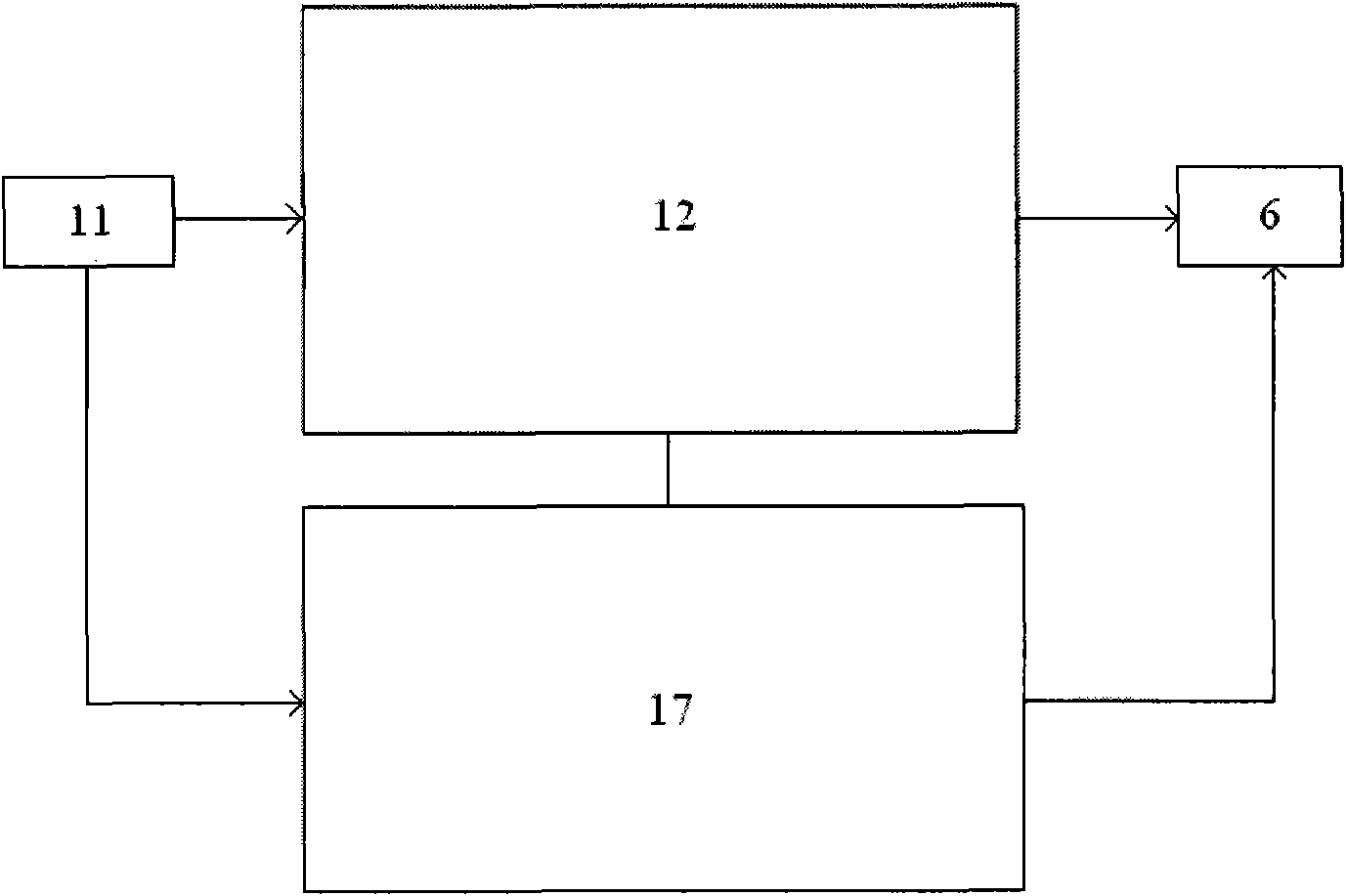

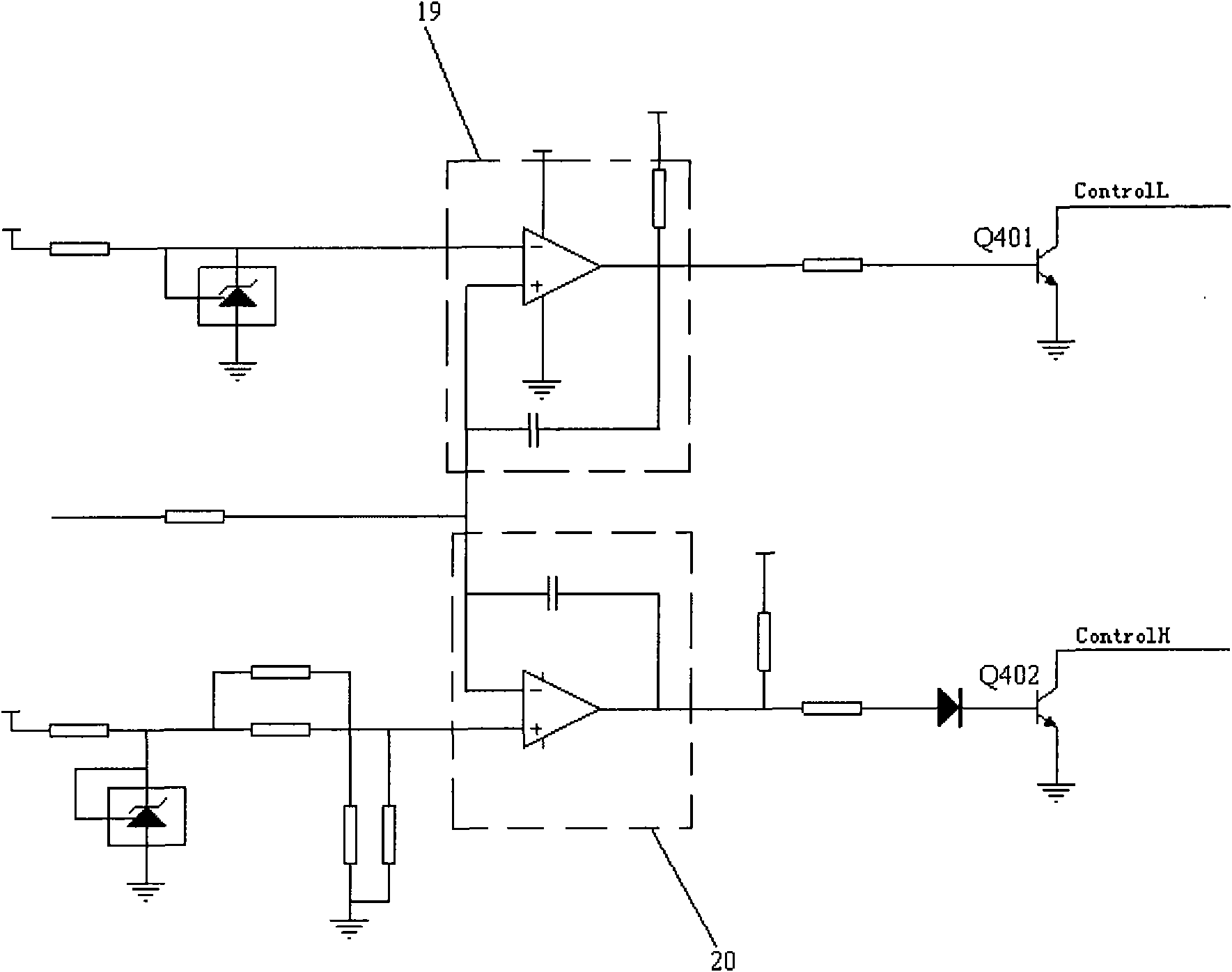

[0013] The brake vacuum boosting control system provided by the present invention includes a main ECU 12 and a main control loop, the main ECU 12 is connected to the main control loop, the main ECU 12 is used to receive an electrical signal indicating the air pressure value, and according to the electrical signal The signal outputs control signals through the main control loop to control the vacuum pump 6. The control system also includes a slave ECU 17 and a slave control loop. The slave ECU 17 is connected to the master ECU 12 and the slave control loop respectively. The slave The ECU 17 is used to replace the main ECU 12 to receive the electrical signal indicating the air pressure value when at least one of the main ECU 12 and the main control loop is in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com